How much cutting have you done with those consumables? Did you had tried to cut the 316 prior to the 16 ga? There is a good chance you consumable got trashed.

Post pic of fine cut tip and shield

I put together a new stack of fine cut consumables (all I have until tomorrow) and ran some tests on 16G. It cuts night and day better than last night. I believe trying to cut the 3/16" yesterday initially sent some material where it shouldn’t go and the issue just progressively got worse. I was under the impression I could cut 3/16" with the fine cut consumables just based on the cut chart info. I will be getting some non fine cut consumables tomorrow, re-checking everything and trying some more cutting. So as of now it looks like the thicker material trashed the consumables from the jump and me being very new to this world just did not check them after the first failed cuts. Hopefully I didn’t too much of anyone’s time with this, I greatly appreciate all the responses and help.

I tried the 16G @ 220ipm, 45amps, verified .060 cut height. It cut easily but I am now dealing with a pretty decent positive bevel. It seems to be on all sides of the test part and the consumables look great so I don’t believe its an issue with those.

That is good news. Yes, you can trash a nozzle pretty quick and the fine cut have that smaller orifice so you are projecting all of that energy through it.

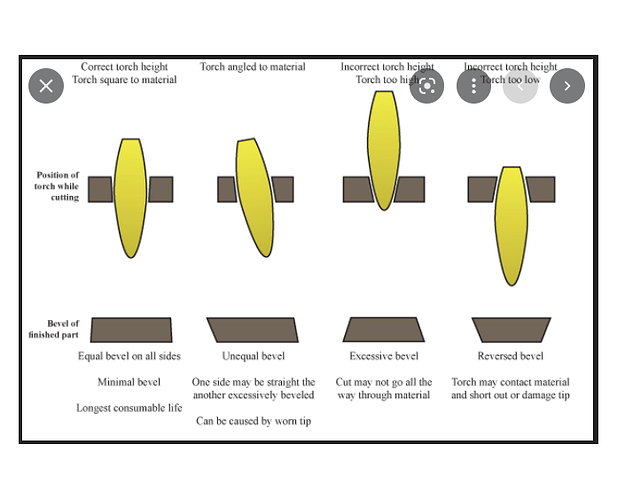

I am sure you have seen this chart/visual. Some bevel is to be expected but when it gets more exaggerated, it merits further investigation.

@ChelanJim I will be digging into the bevel issue more tomorrow when I am back at the shop. I’ve seen other charts but that one is a great visual. It almost points to a torch height issue by the looks of this chart. I know I verified cut height but it seems I’m missing something.

Double check that your torch is mounted square to the table in both directions

Let’s consider THC is deciding it needs to raise the torch to achieve a specific voltage determined in that first .25 inches of cut. Your cut height may be changing.

To take THC out of the picture you could do what Tin says he does: He usually uses the voltage setting, based on Hypertherm’s charts. He states further that when he knows the consumables are wearing and does not trust that they are at their peak, he will then use THC and continue cutting until the consumables need to be replaced.

To try this you make those changes in FireControl:

- Uncheck THC

- Enter the voltage

It is a very valid strategy; especially since you are pretty confident that you cut height is where it needs to be.

Make sure you are cutting the correct direction. Plasma has a good side and a bad side of the cut. You want the bad side on the waste material.

Inside cuts should go counter clockwise and outside should go clockwise

That is very true.

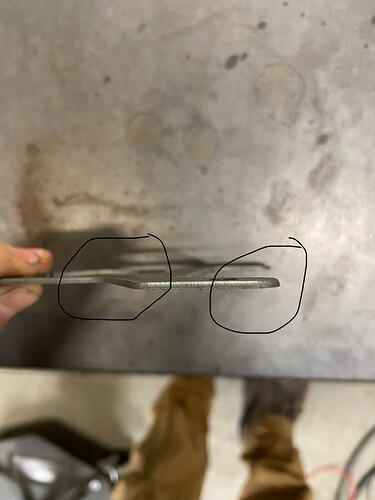

@SpecBuilt, it would be helpful/illustrative for you to share a few photos of your cuts: especially while the pieces are still on the table before separating from the stock piece of metal.

As David mentioned, there could be times that the CAM operation reversed your direction of cut.

Here is how I like to remember the “good” side of the cut. It may seem ‘grade school-ish’ but this seems to stick with me:

All cut directions are correct. I changed to non fine cut consumables this morning and ran a test. I will post pictures of the bevel I am seeing all the way around the part.

@ChelanJim here is a picture of the most recent cut. I even manually input the voltage and the cuts are identical to the cuts utilizing the THC.

I came across a smokin deal on Menard’s (like home depot) this morning on some bluetooth lights. i had to get me a few of these for my trailer. My hope is to wire them in trailer wiring and plug in the 12V inside vehicle when needed. No wiring to switch. Selling out fast. was 1500 when i purchased and 15 mins later only 600 left.

Dang…they sold out fast!

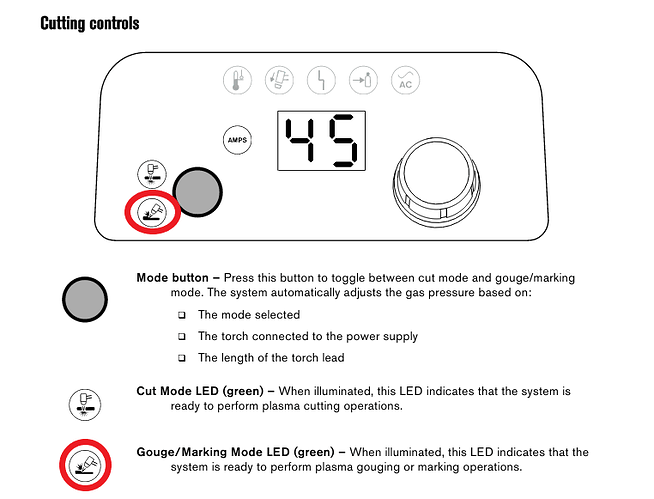

@SpecBuilt - You don’t by chance accidentally have the gouge button pushed/mode selected on the Hypertherm do you? Left side of the control panel, soft button, and two green LEDs. Top one should be lit for cutting.