Hey everyone,

Just wondering how long consumables should be lasting me . I cut signs on 14 gauge steel on a hypertherm 45xp and I can get 4-5 signs done before I start losing the precision . I’m doing a lot of trial and error. Another thing I’m thinking what’s happening is too much moisture in the lines but if anyone is experiencing same issues let me know . Got a pre filter, air dryer and that helps a bit but if anyone has info …

What’s your pierce count and torch time? Post some pictures of your consumables.

You do realize that we have no idea how big your signs are? Are you making 6 inch signs or 48 inch signs?

Ya signs range from 12-20 inch mostly . I’m curious how long they should last . I’m leaning towards having moisture in the line

I also use the 45xp.

Plunge rate should be 60. What amps are you running? At 200 IPM you are using the standard shielded consumables not fine cut.

Unless your signs have an insane amount of interior detail you should be getting far more out of your consumables than that. I’ve quit keeping track of how long mine last because they seem to last so long now that I’ve got all my issues sorted out.

Pics of the cuts and the consumables will tell us more.

I run a harbor freight refrigerated dryer, into a standard filter, then desiccant, then to a motor guard. I’m adding a copper manifold soon as well for good measure.

Thanks for responding back !

Hey guys I’m about to pull the triger on buying the 45xp how was connecting it to the machine? I’m scared to cut into my new plasma lol

You won’t need to open up the machine. Just get either the HT CNC cable or make your own (there are posts with instructions here if you search). For the Crossfire Original you’ll just need the two trigger wires. For the Pro with THC you’ll add the two voltage wires. It’s 10 minutes of work and some parts you can get off Amazon for the CNC port connector.

Iv used the 45 and 65 for a while. With good air and only cutting 12g, you should easily be into the thousands of pierces. Pierces are what put the bulk of the wear on them. I cut 11g, 3/16 and 1/4 alot. Mild steel and I get 2500 up to 4500 pierces with thousands of inches of cut. Lots of variables in your settings, THC and air. I also clean my consumables 2-3 times a day def helps. I still get on average 10 misfires per 3k pierces. Still can’t figure that out but I have a good system of keeping track of everything.

I also prefer the copper plus electrodes. and def have only used hyp consumables. Also I add about .2 seconds per the hyp book pierce suggestions. On 11g I pierce at .4 I do believe. Reason is the delay with LM and plasma. If you are piercing too short, too long or too high things will wear much faster. Your 2 second delay would be too long. It would be more like .3 or .4 for example.

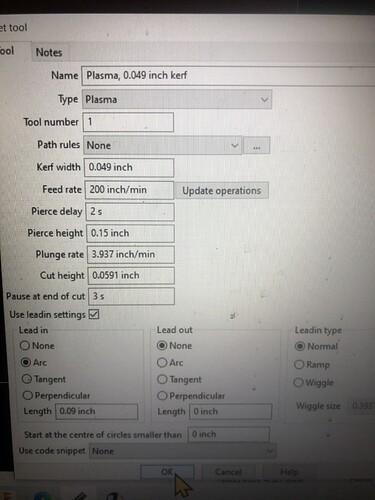

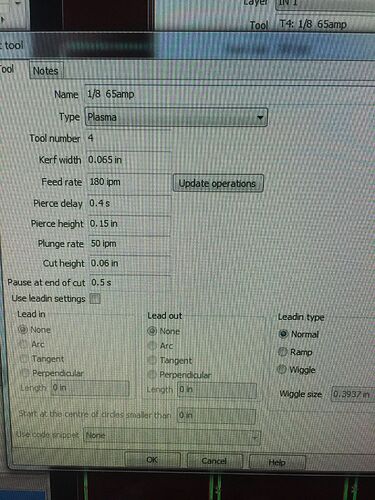

Mind showing me your tool settings on fusion 360 for the hypertherm 45 xp? (if you use fusion) I’m having a hard time wrapping my head around the CAM part of it all. Gotta finish this one job im doing then can finally assemble my table.

I use sheetcam, do yourself a favor and learn it and buy it (cheap) so much easier IMO than fusion. Much faster for me editing stuff also. Once you learn the basics its really easy. Here are my toolsets but keep in mind this is with 65 amp. So just look in your hyp book and it will tell you the kerf with whatever consumables you are using. Your speed will change also. Do you have the PRO and or THC? that to me makes a big diff in the settings. When I used only the XL with no THC the metal was always inconsistent so the cut height was and then that effected speed settings.