Any Tips or Tricks or advice on cutting signs with my NEW Hypertherm 45 Sync ?

So you got it David! Congratulations.

People will develop their own likes/dislikes and preferences but with fine detail, you will want to limit the dross so you don’t damage the pattern. To limit as much dross as possible the cut height is so very important. Use nominal voltage not smart voltage. For small contours to work out, you still want your cut height to be very close to the book settings so check your cut height with Phillips file.

This file will not fire the torch so you will not waste any metal. It will cycle the IHS by touching down to the metal and then lift up to the cut height of 0.060 + 0.02 for springback. Measure with feeler gauge. If you are within a few thousands, you are golden. If the metal is 14 gauge or thicker you won’t need the 0.02 springback so CAM accordingly or cut back on your cut height setting to improve the “realized” cut height.

cut height test.tap (224 Bytes)

In FireControl, set the nominal voltage to what the Hypertherm charts show and you are going to be looking at the “Quality” settings, not “Production.” You are going to be most satisfied with the Fine-Cut since the kerf width is so much thinner so you can get finer details. Remember that Hypertherm is now recommending a slower cut speed if using a water table. Reduce your cut speed up to 20% depending how close the water is to the plate you are cutting. You will know you are too slow if you get undermining of the plate or more backside dross.

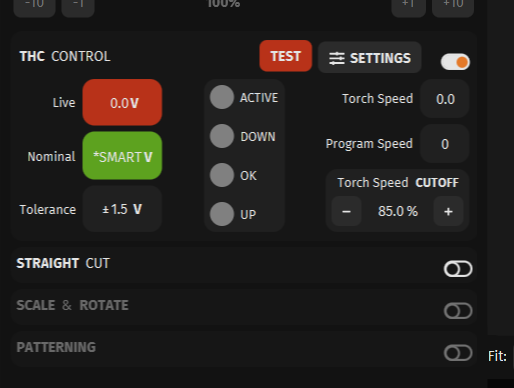

Edit the THC Control portion of FireControl to put the voltage value in where you see “*SMART V”. A value of “0” reverts this back to Smart Voltage.

Now this is assuming that your THC is working correctly.

So all of the above was to establish the best, dross free cut.

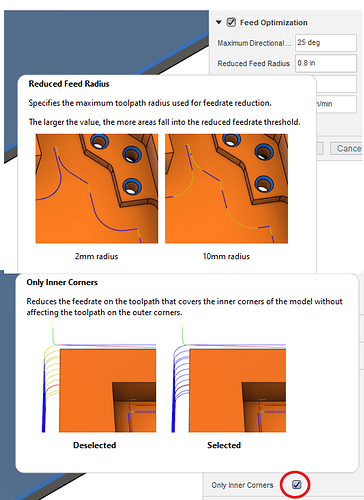

I can’t remember if you use SheetCAM or Fusion but if you have mounting holes that need to be precise, put them on a separate tool path and use feed optimization:

Feed Optimization will improve the cut of the column of the walls of the hole but is likely to increase bottom-side dross. The holes will have enough metal surrounding them that dross removal will not jeopardize the integrity of the sign.

Others will likely have their tips. Hopefully the resident “Sign Master” @Kwikfab will weigh in on this topic! ![]() (Not so private joke…Nelson denies that he makes signs…not true. He makes a lot of very cool signs but “Don’t put that Evil on him!!!” Which means we put lots of “Evil” on him about it!!!)

(Not so private joke…Nelson denies that he makes signs…not true. He makes a lot of very cool signs but “Don’t put that Evil on him!!!” Which means we put lots of “Evil” on him about it!!!)

Good luck and enjoy that new machine!

Don’t listen to Jim, for me signs are a complete waste of time and steel ![]()

But yes, Hypertherm engineers have stated for the longest that their speeds (just like every other plasma cutter) need to be adjusted around your setup.

Seeing as how they perform all their development on a downdraft system, using a waterbed means you should run at a slower speed than book.

I’ve also found to get the best results when the water level was a good inch to inch and a half below the steel being cut.