What’s the best lead in and lead outs and length of them. For a Hypertherm 45 sync machine ?? Trying to learn new things on how to cut with it compared to Razorweld 45…

There’s no reason why they should change at all.

If you have your CAM settings down, then you shouldn’t have to change how you implement rules.

Proper CAM by itself can make a cheap plasma cutter create great quality cuts. Bad CAM can create bad quality cuts even with an expensive plasma cutter and table.

Would you arc in and no lead out work best ??

I’ll preface by saying, I’m no pro as I’m completely self-taught.

With that said, I make tons of parts (and even a few signs, although @ChelanJim will probably say more than just a ‘few’) and I will say that there is no “best” when it comes to lead ins and/or outs.

My lead in types, lengths, and angles (and arc if applicable) are dependent on the geometry I’m cutting out, and more importantly, where I decide to place my lead in.

In other words, some items get absolutely no arc, others do, some get no lead out, where others will.

That’s what I’ve learned through personal experience, and I cut tons of parts with great quality I think, with lead ins that are barely visible.

These two are when I first started CNC, cut on a PrimeWeld CUT60 with PTM-60 torch.

These were cut with about 1 year of experience, on a PrimeWeld CUT60 with UPM-105 torch.

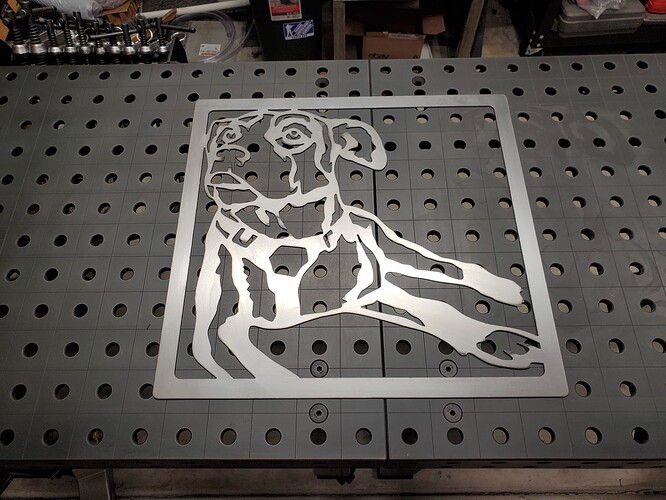

And these were done with 2 years of experience, cut with my Hypertherm 45XP with Duramax machine torch.

I see you’ve been here since 2021 - you definitely have a lot more experience than me. You should use what CAM settings you’ve already developed over the years.

In other words - you got this!

Thanks for all the help !!