My crossfire with Hypertherm 45XP 14ga at 45amps has been cutting fine until today. Now it will start to cut then stop with a message saying the torch started moving, or something to that affect. The cut is not penetrating completely through the metal.

Work clamp? Consumables? Pierce delay needs to be .5

The ground is attached, I changed consumables. I followed Hypertherm’s cut charts, but will experiment with pierce delays and try your setting. What is baffling me is that I loaded a file that I know cuts with it’s saved setting and I had the same problem. Very frustrating because I have two jobs pending.

Ok lets think about this for a min. If your loading a file you know worked before and has not been changed, you probably need to look elsewhere. Think about any changes you have made from when it was working to when you started having trouble.

Double check all the basics

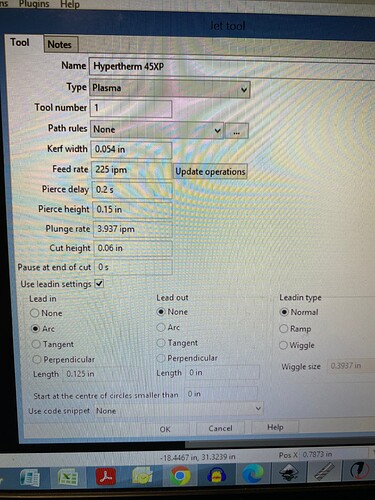

When looking for help from everyone make sure you give complete info.

This is pretty vague, take a pic or a snip of the error.

Ground is attached to part? Cable tight in the clamp?

How is air supply? Looks like there isn’t enough. Maybe a blockage or water.

I’ve been cutting with no problem. I have a gauge I can put at the end of the hose to check the pressure there. Thanks for the input

I’ll check the cable. The plasma cutter is pretty much brand new but I’ll check the cable just the same. Thanks

Yeah I agree it was a pretty vague description. Unit was late, I was tired and at the end of my rope lol.

Trust me, you will reach the end of your rope many times during this learning curve. It’s much harder then people think.

Your hypertherm is capable of a .2 delay but langmuir products need at least .5

@Jmen I looked again your plunge rate is very slow I have mine at 100 Ipm. Also if air pressure drop is your problem you need to be able to check it while cutting

Hi im having a similar problem just trying to do straight cuts hypertherm xp45 it wasn’t cutting just scoring .25 steel now i can’t get the torch to fire at all pauses saying the torch moving before it fires?

What is your pierce, speed,and amps? What kinda shape is your consumables? Where do you have your work clamp?

If it was a tap file that previously worked, the. Use that exact tap file.

Or did you use a previous design file, created the tap with the settings you showed us, and now are experiencing problems?

It will absolutely not work with the settings you showed us, no way those same settings produced a useable tap file for the crossfire.

Trying to cut .25 plate 30 ipm ,pierce delay is .6 sec ,amps 35 i think the first time i tried it xp was on mark\ gouge settings but not the machine torch won’t even fire in test mode so somethings wrong??

Just using the straight line cutting option on fire tried various way thc or not cant get the torch to fire?

any warning codes on the plasma? I would turn amps to 45. you may have damaged consumables with on mark setting.