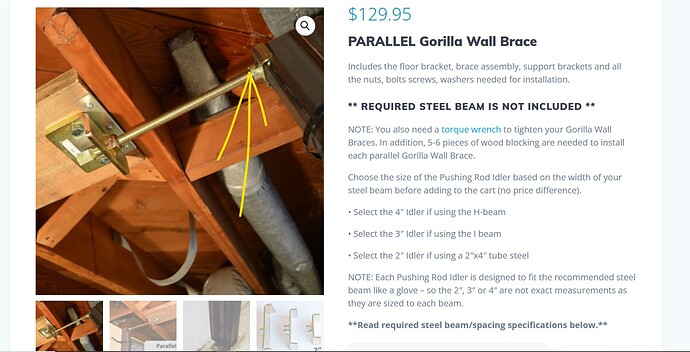

Take a look at the all thread, how would you make up this connection?

would you just have the all thread bottom in the bottom of the female receiving piece?

or maybe some bronze thrust washer in the bottom? (Solid piece no hole)

Or just machine end of bolt flat and flatten bottom of Female piece.

I guess its not going to turn much and very slow, maybe I am over thinking it

It looks like it’s dead head inside the cup on the right, machined off the threads, or just a good slip fit.

Left side has a hex head welded on the threaded rod, then the brace plate has a nut welded.

Easy peasy make out of 1/4 - 3/8 flat stock and some 3/4 all thread and a few nuts

So you’re thinking on the right hand side they just cut that all thread off and bottoms out in the hole ?

I was wondering if maybe It had some type of a bronze washer in the bottom to help keep it from galling being steel on steel

This might work. They have multiple options and sizes.

I wouldn’t worry about galling, I presume this is a one time use thingy. Even 5 times you should be ok as long as the end of the rod is square to the push plate.

Add a dab of grease on the end