Also looking at pic. To me it looks like the lead ins are on wrong side of the cut

Try a shorter pierce delay and see what works. My Everlast works fine with a .2 sec pierce delay.

Make sure you change your plunge rate in Sheetcam. The default setting is something like 3.9 IPM, which is way too slow.

Book calls for 0.1s Pierce. So I’m set at

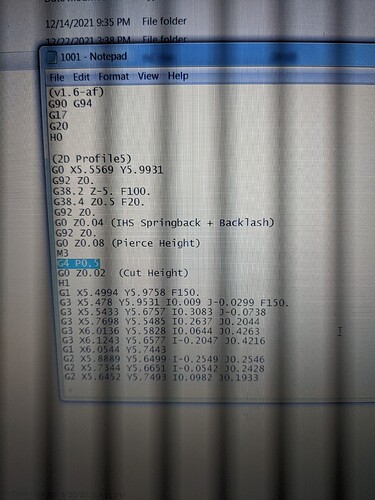

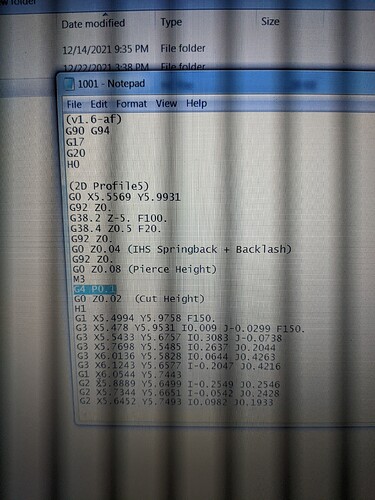

0.5s . I think you’re right about editing the gcode. I’m not sure where . I’ll look at the g code and see if I can figure out where to add the 0.4 s

In sheet cam set pierce delay .5,

post your file to create gcode should set all pierces times to .5. then you need to open the cut file with a text editor, I use notepad. Change the first G4 line to P0.1 as the first pierce does not have a delay.

I went back and changed the first g4 to p0.1 also changed from inside NO offset to outside offset . It looks like it should work , I try again tomorrow

Thanks For you help !

Problem solved . Lead in was wrong.

Can I see how to add that g code.

Running some stainless steel with that g code @madman ?

Those are pretty cool.

That’s silhouette came out awesome

Silhouette came out good , but the rings need some work. next one I widen The rings alittle. To create a little less heat.

Thank you for that information that was a world of help I was unable to completely understand what was going on with the cables because I don’t know anything about plasma tables I’ve been a welder and cutting for years I wish they would clear up the information on how to hook these up when you have the direct connect