Why on earth would Langmuir make the home location Y+ and X-??? Or why not allow us to change the home location? The only option that makes sense is 0,0. They should put bold print on the website “These are horribly designed, read the install directions before you purchase.” Now I can’t even return this garbage since I cut the cord to length them. I made it years with no limit switches, finally made some sheet guides for indexing, figured limit switches would make loading sheets easy. Slide the sheet on till it hits my guides, home machine, cut. I just wasted time hooking these things up only to discover that the y switch goes on the Y+ side. Unless there is a work around for this, these things are going in the garbage.

Just make your guides square it up with the upper left corner and set your origin there. Has worked fine for me for months.

But you have to do all of your CAM wrong then. So if you’re using sheetcam and you want your cut to be .25 from the edge of the material you’d have to: know the dimensions of your cut exactly, take your y location of your stop and subtract your part y length and .25 and type that in to the Y coordinate when nesting your part. OR… If they made home be 0,0 you’d just have to type in .25. But that would make too much sense.

Or what if you just want to straight cut a bunch of pieces of strap at 39"? If they did their homing switches correctly I could lay them all on the table, home, go to 39" and cut x+.

They set home there because that is where the limit switches are installed.

Could you just do you CAM as you normally would then switch the origin to the upper left corner in fire control?

I bought the limit switches when they came out but haven’t installed them. My procedure without them works for the little bit of cutting I do.

I believe Erik nailed it on the head TWICE:

- that was the most convenient spot to mount the limit switch; and,

- you can mark the origin of your drawing to line up with that back left corner.

I have them installed but turned off the soft limits. I am really not using them so I agree with @MMFab. Had I known how they were going to work, I would not have bought them.

I am still waiting to see if they help with indexed cuts. I have not cut anything larger than the table but if I do, I think the limit switches with be helpful. Scenario:

- Home machine then move to start coordinates.

- Cut pattern.

- Move metal

- Home machine then move to start coordinates.

- Cut pattern.

Your system sounds good. Agreed that you probably did not gain much.

The limit switches go on either end of the Y axis without a problem. That’s where I put mine before I realized that LS did it backwards.

The ends of the machine are the same, limit switch mounts either way exactly the same. Won’t work on the motor end of my table because my expansion gives me like 54" of y travel but my water table is 49". So if I want it to zero on the water it has to be at 0,0.

I just can’t wrap my mind around why anyone would want it to home anywhere other than 0,0. If they wanted it home at that side of the table then the y axis should be reversed. It makes zero sense.

You’d think it would be easy for them to allow you to pick your home corner. This is the only way that makes sense to me.

Maybe that’s the problem. I am glad LS did it the way they did because if they hadn’t everyone but you would be pissed. ![]()

But why is home not 0,0? Standing at Y 0 is the only location where your arrow keys on your laptop actually move the torch the same direction. Which is conveniently at 0,0.

I don’t understand what you mean sorry. I don’t use a laptop so maybe that’s why. My arrow buttons work just like I would expect

Ok so maybe I get it now. I have a XR so my monitor goes on one corner of the table only.

if you were to move your lap top to another corner would it work the the way you want it too?

What determined where you mount you laptop?

and your laptop is in the same location as my monitor. Standing where your lap top is my table homes back and left

I get what he is saying and that has been the major source of confusion with these limit switches, even on the XR. Most programs have the origin at X0/Y0 by default and that point is the front left corner. This is the source of every one of the new XR owners complaining that their project is “outside the table limits” when they load a program.

Most of the world is just used to the “home” position being X0/Y0 with any movement from there being in the positive direction. Langmuir’s break in prgram for the Crossfire and the Pro both start from the X0/Y0 point at the front left of the table. Since the introduction of the limit switches with the “home position” at the rear left, there has been no shortage of people who can’t figure out how to run the break in program. The reason being that the origin in at the front left and, when they load it at the “home” position, the whole program is outside the table limits.

you are correct this was confusing for me at first also. Now I don’t even think about it. Now If I had one that was one way and one that was the other that might be tough for me.

I really don’t pay much attention to where I place my origin in fusion anymore as long as Z is up. If I go to cut it and its not where I want it, I move it with FC. I really dont think much about it

Most of us can learn to work with anything.

In the OP’s case, the "home- position is outside the water table on his extended table.

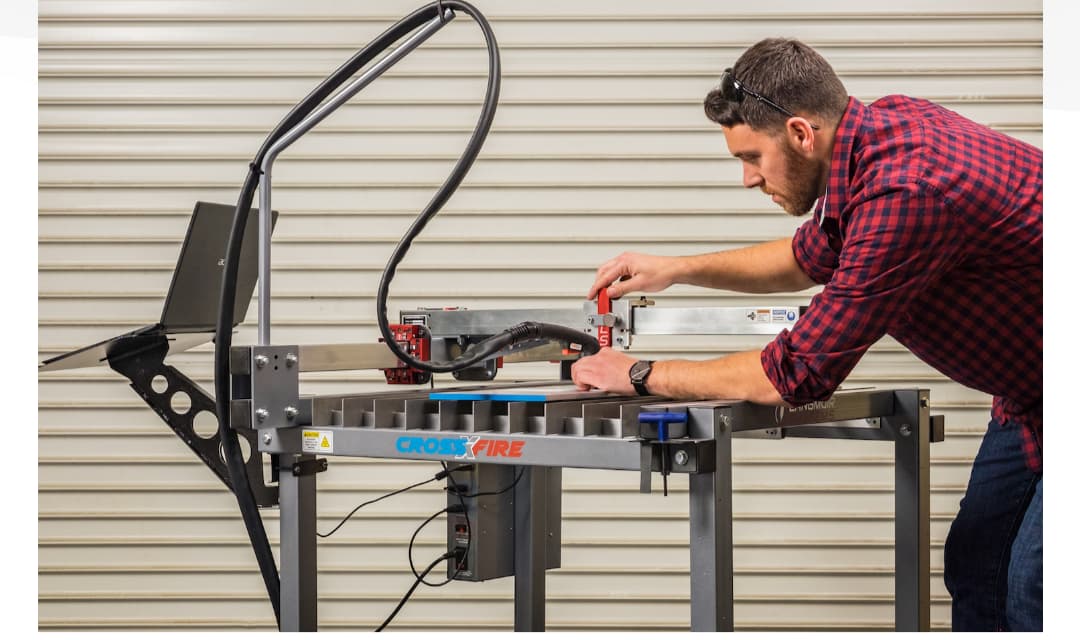

That’s a photo of where langmuir puts the laptop on the OG table. If you put your laptop there and push the up button, the torch jogs to your left. Push the left button? It comes back towards you. Also if you were to feed a sheet under the y axis to index cut, you are now standing in the way. If you turn the laptop so you’re standing at y0 looking y+ then the buttons correspond with the correct jog direction. You can also see better because there isn’t a y rail in your way.

Well I agree that is pretty stupid. I guess what got me to even respond to your post, was how you went about wording it.

You have a legitimate gripe, the problem for me was how you came in looking for help (at least I think you were) and went off the deep end.

I can tell you right now there are maybe 3-4 guys in here that will put up with that shit. My suggestion would be to find some posts that have lots of responses and see how they worded there request for help.

Back to your problem. I would have seen what other people would have done to try and resolve this. If none of them seemed like they would work for me, I would have then put my thinking cap on and try to find a way to fix it or learn to live with it. I find fixing things like this (if I can)very rewarding.

Lets us know what you decide to do, maybe someone else can benefit from your post!

Thanks, but I don’t need a lecture from you on how to communicate. I don’t post here much but I’m no stranger to forums, I even was a moderator on a pretty large one for many years. I didn’t ask for your advice on how to type, so keep it to yourself. My complaints were clearly not directed at any members here, just langmuir.

I bought a LS table within their first year of business. Dealt with all their instructions, followed all their material. Have done thousands of cuts. They have a history of referencing using x0y0 as a location to base their cuts from. Even their fire control videos on YouTube have all their parts in that orientation. It would only be reasonable to believe when you purchase a homing kit from them that it would be consistent with how they have operated in the past. It should at least give you the option to choose which end is home. The switch mounts identical on either end of the y axis. It seems like adding a simple option would ease a lot of customer complaints. I’ve heard maybe 3-5 people in all my searches of this forum who are pleased that they purchased the switch kit. Maybe that’s a hint?

I have a pro with limits and use fusion. I actually really enjoy my limit switches on the pro. It does “home” wrong I agree. However I think if it more as parking and a zero reference so it knows where home is. I’ve ran large CNC band saws that find zero by homing at the top of the stroke and not the actual zero point.

On the pro when you send it home it gets the torch and gantry out of the way so you can load your steel. I have to think that was the design intent in addition to having a constant reference point. Fusion makes you pick your zero anyways so it’s a step required no matter where zero on a machine. Also I screw up enough cuts that the homing switches let me go back and finish a lot easier as well as aid in index cuts.

Maybe we could get them to rename the button to load position?