What is the best setting for hole cutting you have experienced on Lead in / Lead outs. Tangent / Arc / etc… I use Sheetcam for Cam… And how to set up Sheetcam for good holes ??? For lead in / out

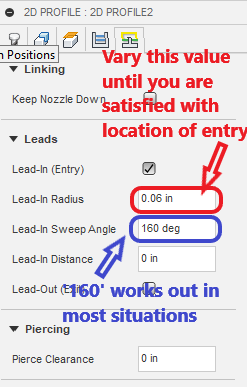

Recently I switched from tangent (90 deg) lead-ins / outs to arcs with no lead-out. My hole cutting quality has definitely improved.

The holes are .080" and .125" in 18ga.

Totally agree with @Simsworx!

With SheetCAM, you can select to start holes in the center. I don’t use SheetCAM but I know this can be made a default setting and then the torch will spiral outward to do the cut.

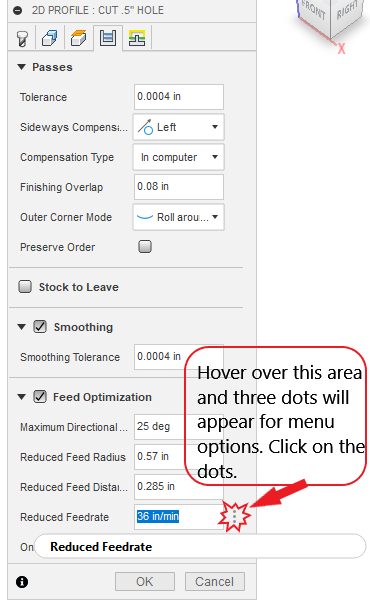

In Fusion360, with some simple experimentation you can get a similar result as follows. (You will vary the micro radius amount until you are satsified with the starting location. It does not have to be exactly in the center to cut well.)

This tab “Passes” shows optimization settings (speed is slowed to improve cut of holes) as well as decreasing tolerance to improve selection of holes. Adding a “finishing overlap” assures a complete cut out of the hole when a lead-out is not used.

holes are best also cut at 60% slower that the rest of the cuts and in a counterclockwise direction.

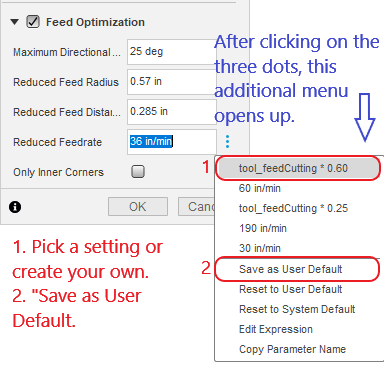

I don’t have to think about the optimization setting anymore since I set my speed to always establish 60% feedrate once I pick “Feed Optimization.”

This is yet another tip I picked up from one of Tin’s videos:

Most of the options in CAM in Fusion 360 can be modified so the default setting matches what you normally pick. Here is how you do it:

Now the real magic starts:

Now, everytime you open up a tab with choices, you can choose to change them this once or click on the three dots for additional quick response or set a default.

This works throughout Fusion 360. I have done this with Pierce Clearance (0.0), Finishing Overlap (0.01), Lead-In Sweep Angle (160) and all of my post properties (Cut Height, IHS springback, Pierce Delay, and Pierce height) and many other areas. This has really cut down on trying to remember all of my settings.

Edit: I have since realized that the post-processor values just re-populate with the last settings that you used in Fusion 360. The 3-dot menu does not appear to give the same option to “Save as User Default.” I found this out when I loaded someone else’s f3d file and went to the post processor menu. The next time I was trying to processor g-code for myself with another item, I saw all of these “foreign” values.

Great tips Jim! Thanks!!

I see that OP has edited the original question and SheetCAM is what he primarily uses.

@Simsworx or @ds690 do you have a way to explain specifically how you would set up cutting of holes in SheetCAM or is it fairly self-explanatory. That is out of my wheelhouse.

Sorry for perhaps overstepping OP in this dialogue.

I might suggest that this be moved to the SheetCAM category. If that is okay with @Allcutup, we could move it or you could move it. You might get more pertinent information.

I use the “start at center of circles” feature for anything smaller than .75". I have tried overcut and lead outs and neither seems to improve the quality of the holes over just using the start at center feature with no lead out.

Here’s a comparison:

Same pattern (1x3, .125, .250, .375 holes), top piece is start from center. Bottom is arc lead in, no lead out. (.07" length) Dimensionally, start from center was .004" closer to true. (Arc was wider on one axis for .125" hole)

Same parts, back side, un cleaned. The arc in has a touch more dross at one side of the hole, presumably lead-in location.

Personally, they both look really good to me!

Indeed and I LOVE the scientific methodology!

Don’t you know you’re supposed to change 5 parameters, material, and patterns in some random fashion so you have the most coverage in your experiments? ![]()

That you even ‘experiment’ is somewhat unique!