First off, I apologize to any Machinist, Weldor, or seasoned Fabricator. What you are about to see is simply “what I know” and I mean no disrespect and do not claim to be a “tradesmen”.

I’m just a guy that likes tools and metal working; I am in no position to “give advice”, just having fun.

Carry on!!!

So there I am, wanting to use my hoist to lift my tractor to work on it.

After some “looking around” I find an idea that intruiges me.

I wish I could remember where it was from, and who came up with the idea, but I can’t.

Anyway, its basically “large footprint hoist pads”, so you can drive up on them, secure the front tires, and safely lift my tractor.

The first one I made, was “Pre-Langmuir” so I drilled everything “old school”

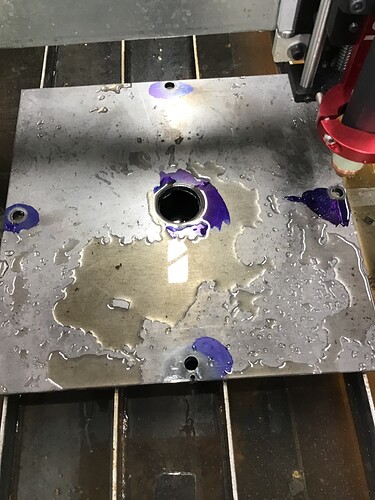

Howerever the next 3 were cut using my Crossfire!!!

Wow, that is a game changer for sure!!!

Here I am cutting out the “plates”…Took about 45 seconds per plate, after I got them “aligned”

from a different thread, I had to use “witness marks” to try and get each plate cut “about the same”

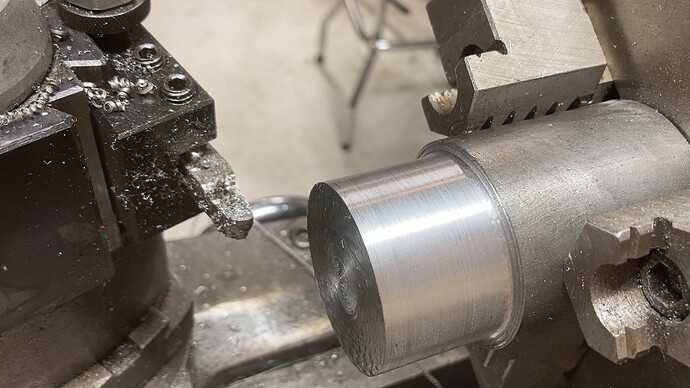

Then it was off to the lathe to turn down the ends of the parts that will go into the hoist and eventually be welded to the above “plates”.

First I “face it”

Now I turn down one end to go in the “hoist eye”

I haven’t learned how to use the cross slide to actually measure how far I have cut, so I just have to “creep up” on it, and keep checking it.

Not a great finish, so I “cheat” and get some “emery cloth” to clean it up a bit.

Now I flip it and turn the “plate side”, but my battery died, so here is the end result of the “turned pieces”

I since they are so big, I decide to “pre heat” them so I put them in the oven at 500 degrees for about 1.5’ish hours.

Here is the first pass…My “welding positioner” crapped out on me, so I had to go “old school” and had to keep stopping to turn the piece.

1st pass

2nd pass. For some reason my subsequent passes, never look as good as my first…

3rd pass