hey its bender just wanted to introduce myself to the forum. just got my brand new xr running with hypertherm 65sync. having some issues with plasma creating bevels. does anyone have ways to correct this? any thing would be greatly appreciated thanks!

Welcome! Can you send a few photos describing your bevels?

How bad are they? You will never get a perfect edge. Like Craig said post some Pictures

Also need your settings? cut height, speed, amps, Etc.

what thickness material?

Uh, Newbies can’t post pictures…

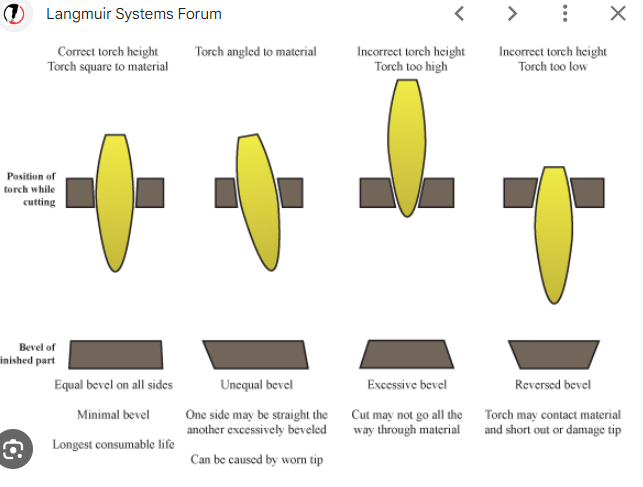

Seems to me @toolboy had a diagram showing the causes of bevels.

welll…helllooooo…darling…

yup…I am back and here is a picture…

At first sight, it looks like your torch isn’t too physically straight up and down. Anyone comment on this?

That’s what it looks like to me. Bevels in the same direction and only on one axis from the photo.

i made some adjustments to the z axis rollers to level head and its running better. i did notice now the paint is pealin off on the top where the roller contacts. i didnt over tighten it…did anyone else have paint peelin off

Welcome to the forum Bender!

I see you are already on the way to solving your bevel question. This might be a good time to look at some other reasons for “cut angularity.”

Troubleshooting plasma cutting system cut quality problems - cut angularity.pdf (669.7 KB)

thanks man! i appreciate everyones help on this forum so far!

@Bender welcome to the forum

Check the cut heights for the Hypertherm SYNC they a much higher cut height compared to the Hypertherm PowerMAX.

yea i believe im running at .125.

thanks man!

Great post on the bevels. Looks like I need to adjust

I am going to erase that graphic from the internet if it’s the last thing I do.