Langmuir stands behind their stuff. Just last week, my Z axis had worn out completely. They sent me an entire Z-axis at no charge. My table is five years old. Your problem has a common denominator. Whether it is the control system or the plasma cutter’s fault. Sorry to say, you need to eliminate things one at a time to figure it out.

At this point I think throwing parts at the Langmuir side of it is just a waste of parts and time

800-643-9878 Tel (Technical Service) Hypertherm

Here’s your manual for the Hypertherm

troubleshooting starts on page 85

I think it’s been assumed but you have tried a brand new set of consumables, right?

I used my fine tip and regular tip so yea

What is air pressure supply from air compressor to inlet of plasma cutter, have you gone into the plasma cutter menu and actually see what the air pressure set itself to and what do you have for air filtration? maybe there is a restriction at filter on plasma cutter inlet or at filters anything is possible don’t assume there is plenty of air volume getting to torch…

80 psi I have a air regulator with 4 compartments 2 are drying needs and on the plasma is a water

catch

Bypass all that and just plug your compressor directly in the plasma cutter and try again. NOT OVER 135PSI INPUT

I’m starting to think that all these restrictions are adding up to a lot of static pressure drop akin to an orifice. And that this SYNC does have an automatic reset for air pressure.

My non sync 65 will reset itself for a low air pressure issue. I am sure the sync will as well. The only time I have to reset the plasma is when I remove the consumable stack.

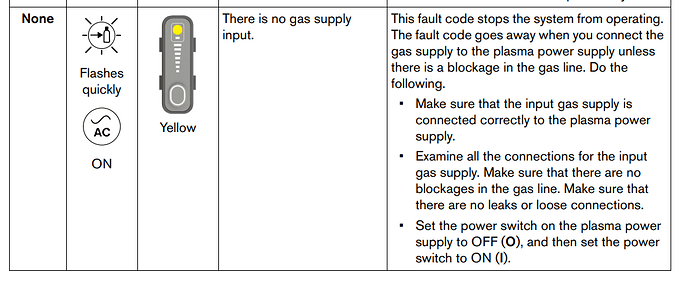

YES @Phillipw Once air pressure supplied the fault will clear itself. I guess it’s every other fault that needs a manual reset besides the air… even with the XP.

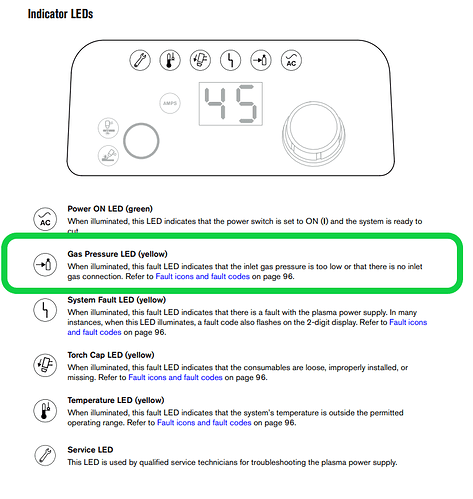

The OP must have seen this warning light come on during all these tests

So there is a possibility he is running out of air and the plasma resets before seen.

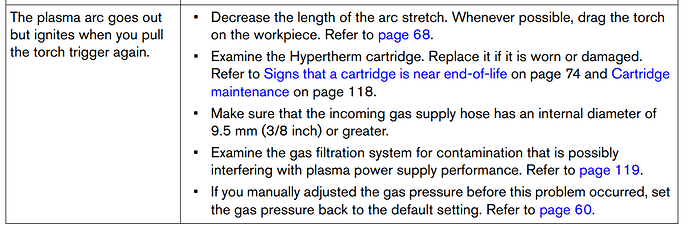

I think we’re zeroing in on an answer. His pressure drop is so extreme that it’s acting like an orifice he only gets 7 inches of cutting before it cuts out the ARC. But then recharges enough to clear the code and be able to perform another 7 inch test.

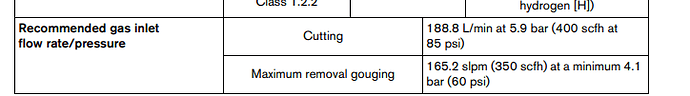

I nothing else is on the air compressor besides cutter . I also switched out for a fatter hose. On the plasma itself it’s set for 60 psi. Max is 69psi And it still firing a partial arc.

That worked

That’s great. I can mark this thread solved?

I have not dryer on my plasma

I guess so

You should have a dryer but you’re gonna have to figure out what’s causing your extreme air restriction

My air compressor definitely spits out a lot of water. I’m not gonna lie on that like I’ve only had my aircraft presser running twice in the beads are already pink in the dryer itself.

Well that’s nowhere near the amount of desiccant required for a system like you have. You should at least have a quart of desiccant myself I use a gallon. Plus you should have some kind of water removal system before the desiccant to take the load off the desiccant. Like 20 feet of metal pipe or even a refrigerated air dryer. Most plasma cutters want you to have at least 20 feet of pipe between the compressor and the plasma cutter with the drip tee this will help the air cooled down and release its moisture.

If you had a pressure gauge right at the inlet of your plasma cutter I’m sure you would have seen an extreme pressure drop from static to dynamic once you fired your torch. In a properly piped system you should only see two PSI drop.