ok thank you guys when i get home will try it and let you guys know thank you so much.

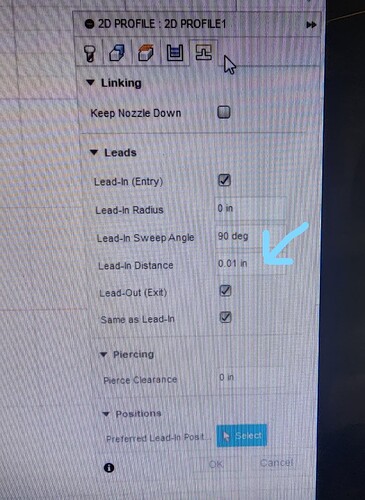

Watch your lead in/out length on narrow cuts like that. If they are too long, the cuts will be discarded.

i had read that sometimes they put them to o. or what would be a good lead in /out

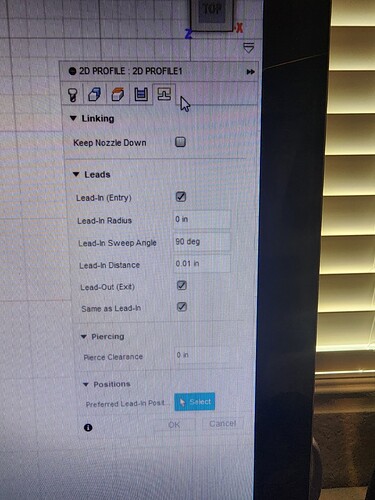

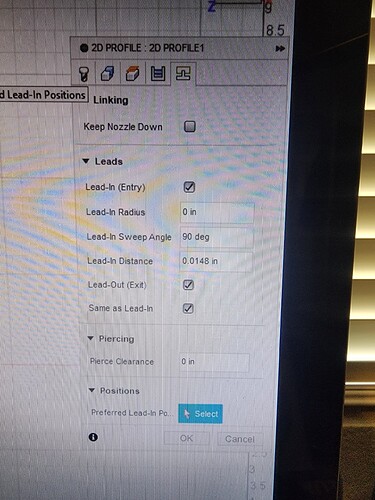

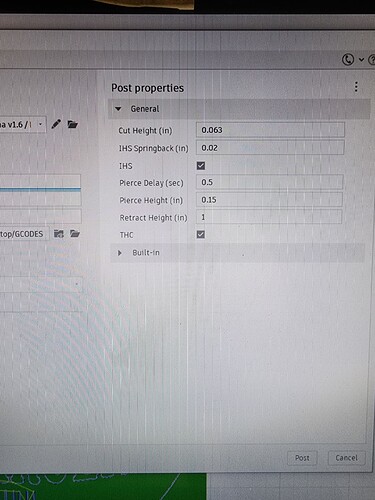

You might have to make it zero for small openings. Always set the “pierce clearance” setting to zero, because it adds to the lead in.

I normally use .1" lead in, but I will cut it down to .060" for small areas. I use Sheetcam, so it will automatically delete the lead in, if it doesn’t fit.

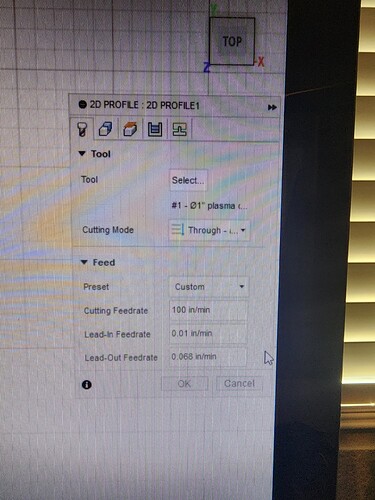

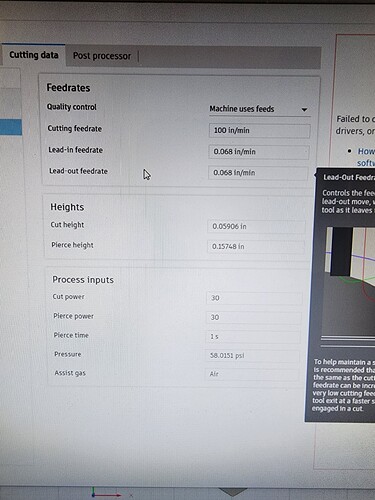

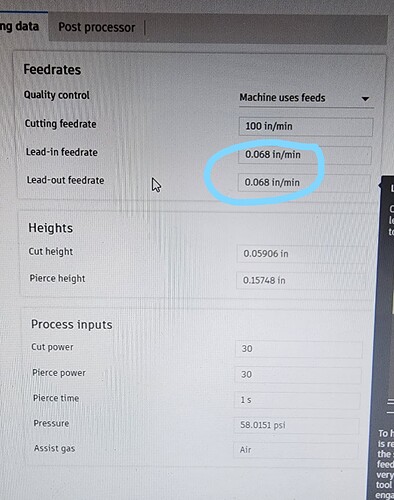

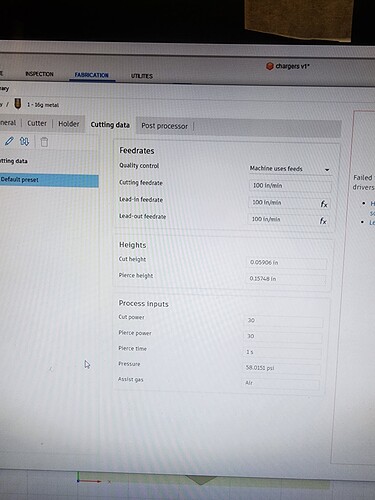

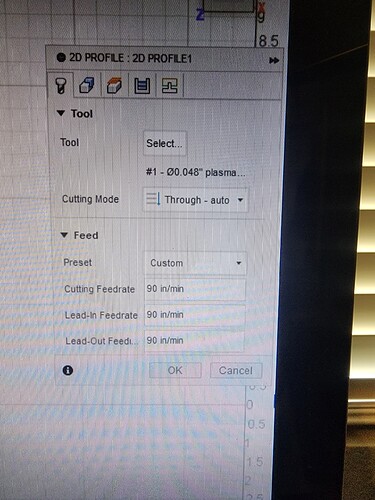

Watch the values for your lead in and lead out feed rate, They do not look right.

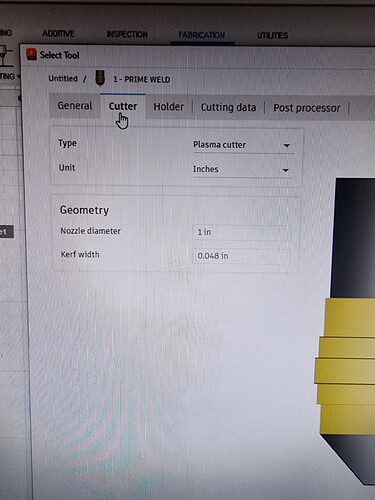

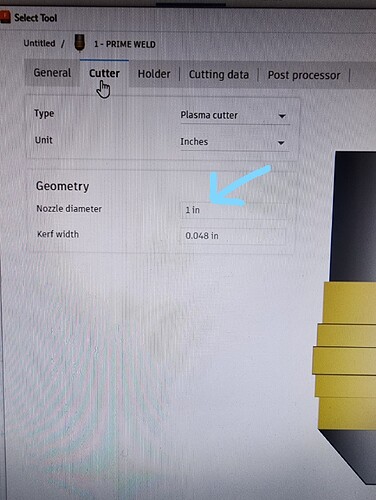

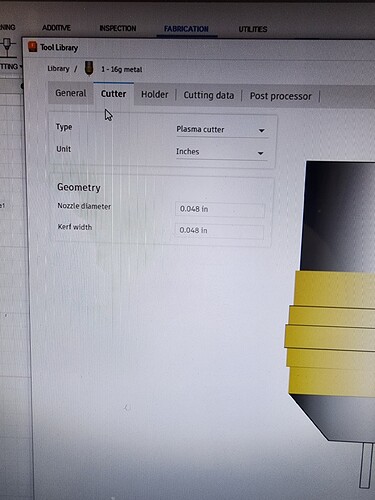

And if you switch your nozzle diameter in your tool parameters to the same value as the kerf width your simulation will look a lot better

As Tin said, change your lead in/out feedrate. It should usually be the same as the cutting feedrate. With the super slow feedrates you have in the lead in and lead out, the torch will burn out before it moves through the lead in.

This setting is how fast the torch moves during the lead in/out. These should be the same as the cutting feedrate.

This is where you set the distance of the lead in/out. .010" is not long enough. It should usually be at least as large as the kerf width.

This number should be the same as the kerf width, so that your simulation image will show the actual width of the cut paths. It won’t affect cutting, but it makes it easier to see where the torch will travel.

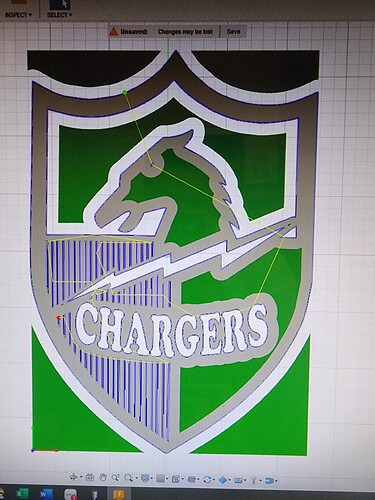

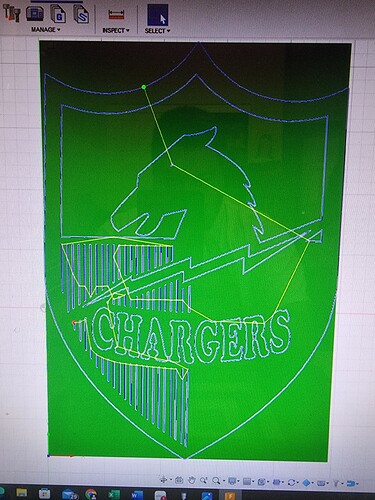

I’m worried about all the small lines.

I wonder if there’s a way to just do single line cuts (you’re likely going to end up with a pierce starting bite anyhow with the micro lead-ins on those slots) or bridge several cuts so let’s say three slots could be cut with one pierce. Thermal distortions going to be a concern.

You could increase the thickness of the lines and make less of them? It might work out just fine.

When I have projects that are busy like that sometimes I’ll have a pitch of water and just pour it on the sheet while it’s being cut to keep the heat down.

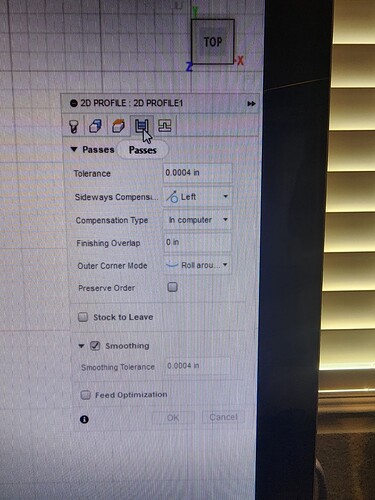

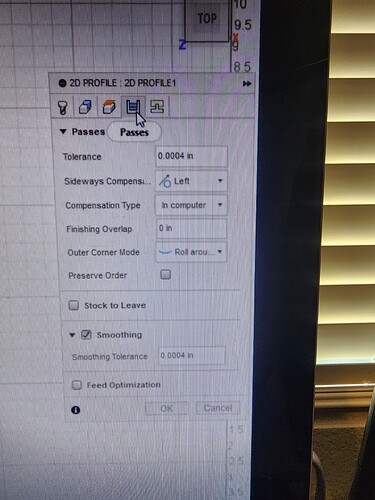

I usually like to drop smoothing and tolerance by one magnitude.

The bridge between the a and the g may be problematic as well.

Think about getting rid of the lead out and replacing it with a small finishing overlap instead. Or no lead out or finishing overlap

Gave it a try will clean up tomorrow and see how it comes out cleaned up

Looks ![]() great

great

If you are into sports signs, I’ve posted several on Fireshare. NFL only ones requested by friends; Steelers and Patriots.