I will go out after dinner to get change the deli height and for the programs

When I change it to the 14ga I ran it at 220ipm

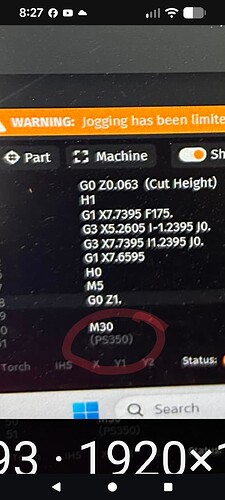

Hell when I first cut I had the first cut at 350ipm and each cut after I dropped it by 75ipm

Change Pierce time to .75 changed cutting height is at .2 piercing height is at.15 and curing at 220ipm and it’s 14 ga

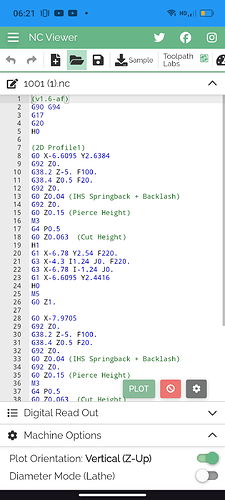

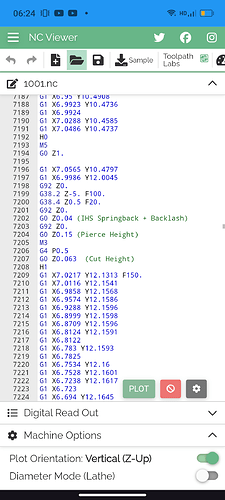

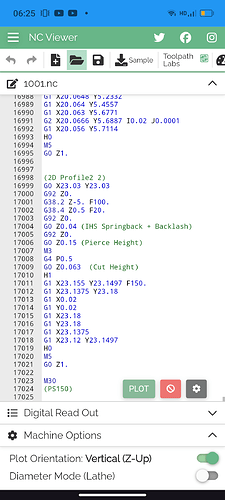

1001.nc (649 Bytes)

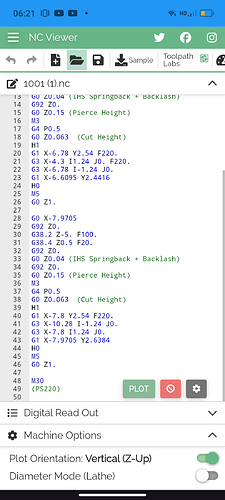

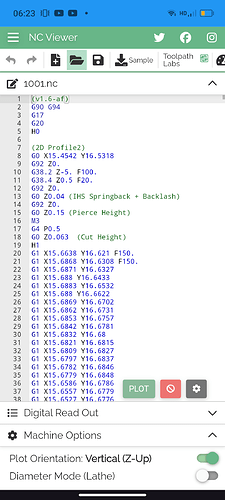

1001.nc (333.6 KB) good program

I’ll chime in tomorrow when I look them up; can’t find my controller and don’t want to dig for it with the kiddo asleep ![]()

According to what you posted above your cut height higher than your pierce height? Is this a typo? Did you mean you set your cut height to 0.02?

Cut is .02

P h is .150

Sorry about that

I figured it was a typo. Just wanted to verify the typo was in the message not the input.

I’ll wait to hear @Kwikfab analysis of the nc file.

I am also going to call tech support tomorrow see what they say. I only been cutting for a week

Looks like fusion didn’t change anything. I have changed the all that multiple times I may be doing it in the wrong area.

I want to thank y’all for all your help.

I just got off the phone with Langmuir and I have a faulty motion control board

But I really appreciate everybody helping me thank you so much