Not selling… YET!

Ok… so I’ve had it the table for about 4 months… no cuts yet… trying to stay away from splicing and cutting wires in plasma… bought a new hand torch(one arm) and cnc cable… only to find out it doestn work with hand torch… so bought a new machine torch(the leg) and still getting the same error… WTH am I doing wrong? Thanks.

you need to supply us with more information please…

what plasma machine do you have?

what model hand torch…what model machine torch…

where did you buy the CNC cable from…information on that also.

do you have the crossfire Pro?..or the 2x2 crossfire?

do you have THC on your table…?

what design and post processing software are you using?..

that is the start…

Thanks… I have the crossfire with xl kit and water table. Trying to use Hypertherm 45… tried factory hand torch and now T45m machine torch

still need some information…

you have the following

2x2 table

XL kit with THC

Hypertherm 45

Factory hand torch and T45m Machine torch

CNC cable?

design and post processing software?

Are you also using Firecontrol?

laptop or PC?

Xl kit no thc(height control)

Yes for cnc cable

Using Firecontrol along with Sheetcam…

PC…

now we are getting somewhere…

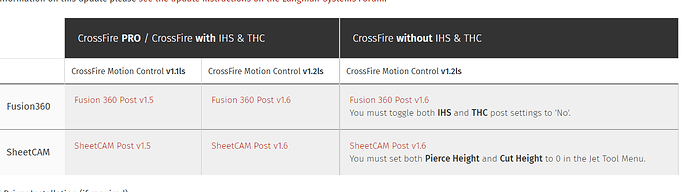

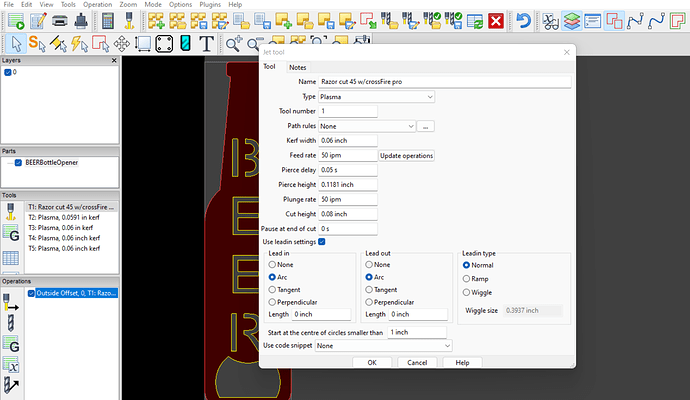

I believe you have downloaded the wrong post processor for sheetcam

you need to download and install the postprocessor for sheetcam that without THC and IHS…that way you will not get the error.

best way I think …delete sheetcam and all related stuff…then reload sheetcam and download the proper

post processor…the one on the bottom right of the picture. and follow the settings recommended.

then try again…

There is only one Post Processor for Sheetcam (and Fusion360 also), so you need to set the Cut height and Pierce Height to zero in Sheetcam. Otherwise the Post Processor will insert the IHS(Initial Height Sensing) loops in the file. Your machine doesn’t have a Z-axis, so it is looking for IHS data that doesn’t exist.

Ok for you that chimed in… thank you so much…I really do appreciate the help… the torch is working… it was the pierce and cut height. I’m very green to this stuff so again thank you…

I have the crosfire pro from languir and I can not get to cutting without something going wrong !

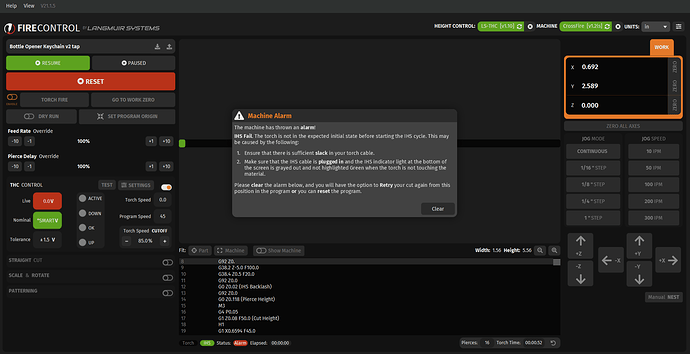

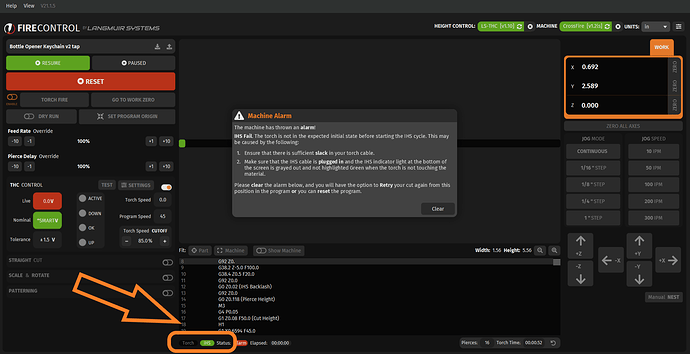

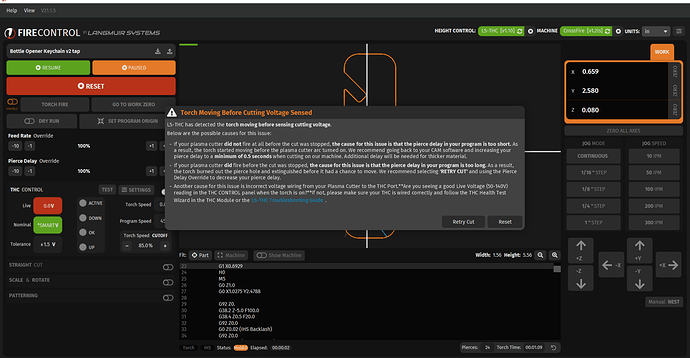

sorry sent it with out the information needed , just getting frustrated , the error below is what i am getting , i a m using the razor weld cut 45 with THC.

if you manually move the torch up and down with the pageup and updown keys at 10 or 50 ipm . Does the IHS light go on and off as you touch off and come back up?

how high up is the torch mounted in the holder?

The blue light will come on and off, not the greenlight. THC screw is about at the halfway point of travel with the torch about 3/16 from material, the letter L on the bracket is just below the hold down strap.

I do a dry run and the THC does not move up and down .

If I am using a 220 v plasma cutter should the selector switch inside the table control box be set at 220v ?

all z height commands are disabled during a dry run

should I have an IHS cable hooked up to the table controller? this is the message it keeps giving me even with the height control off.

the IHS cables are hooked to the langmuir electronic box. where are they hooked to now?

Have you made any cuts on this table before?

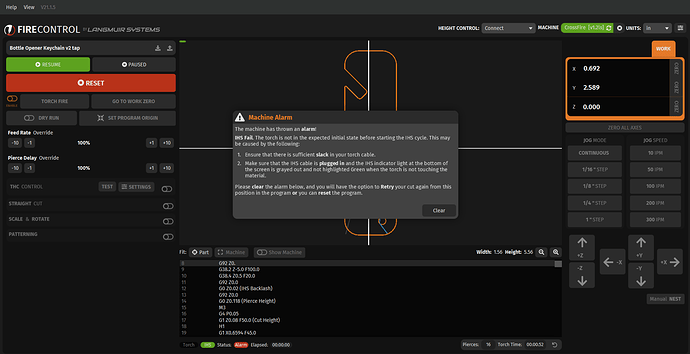

IHS issue resolved now, but I am getting the error below. I have not done any cuts yet. I appreciate the help.

How long is your Pierce delay set for in your program?

.5 sec minimum length to trigger the firing relay.

What ended up resolving your IHS issues?