Just use the leveling feet. Raise them up all the way. Stick a block under the metal frame/leg. Repeat 4 times and lower the feet and take off…… no Jack needed.

id recommend at a minimum build an angle iron base around the bottom of the legs. Be best to do X straps on two sides as well. You try and push that thing too hard up a 1/2" cement joint and might have problems

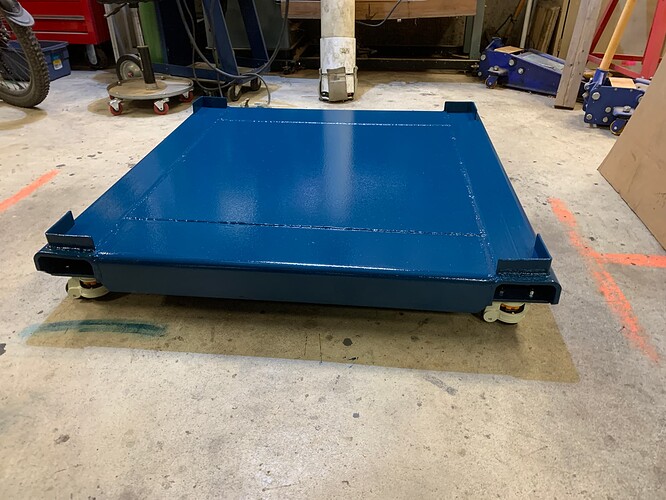

I built a base using those casters/stands, seems to work well. I overbuilt the base because I happened to have some heavy steel lying around from a previous job and I tend to overbuild anyways. I just poured the concrete so no moving the machine for a month at least … but the only reason I put casters on it is if I sell the shop or move out. I eventually cut the legs down 6" on the MR-1 so the working height is maintained, otherwise the rear of the machine would be harder to reach.

Hey i havent gotten my machine yet but id like to build a skid with caster wheels before it shows up. Could you let me know the measurements of yours as a jumping off point?

Sure. The outside measurements are 41" deep by 40" wide. The L shaped holders for the feet are 1 1/2" tall, and are spaced 39" deep (inside to inside) x 38" wide (inside to inside). WIth the L shaped holders, I had to notch them out after these picts where shot to allow for the mounting bolts for the levellers that I bought for the legs from Langmuir, since they protruded out.

The platform ended up being 6 1/2" high, so I lopped off that much on the legs and redrilled the holes for the levellers. Lukily the four legs on the base tub are parallel so they stay at the same spacing.

Hope that helps.

Cheers,

Mike

Does anyone on this thread have dimensions for the stock threaded block they use for the levelling feet? I’d love to make a new one with levelling casters in preparation for my fully assembled machine. Thanks!

All be aware that the casters also come in a ratcheting type and are FAR easier to adjust…