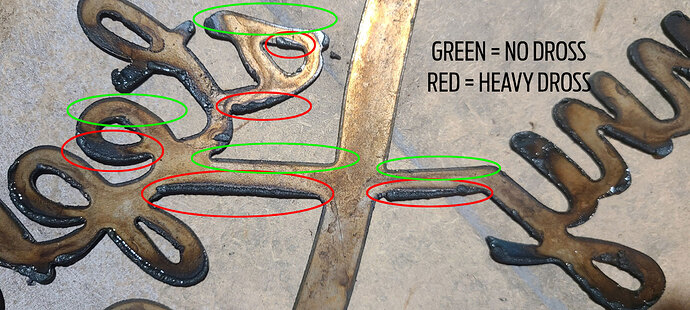

I am getting heavy dross / slag on the right side of the cuts. On the left side, there is virtually nothing! It would be great to get the left side to cut just as clean.

I attached a picture of the bottom side for reference.

I am cutting at 75 psi and 80 ipm on 16 gauge cold rolled steel.

Any ideas? I thought I might need a new swirl ring.

Original Crossfire

Viper Cut i30 torch

x45 torch head

Fire your torch manually out in the air while looking at the plasma cone. If it’s not reasonably symmetric then you need to change the consumables.

1 Like

Thanks for the response! I do a lot of cutting and change out the consumables quite often. For the piece in the picture, I only had about 17 minutes of cut time on the consumables. I write down the cutting time on a white board after every cut. So, the consumables are fresh.

Something else that occurred to me is air pressure. If it’s set too high that can cause weird things and too low doesn’t cut. The plasma cone out in the air should be symmetric and if it’s not then that’s what you need to look into. When it happened to me I had a symmetric looking cone except for a small jet shooting out on one side and changing the consumables fixed it.

1 Like

As said, try a new cutting tip. It is also over heating the side with the dross for some reason. Air pressure is a little high. You are also at a disadvantage using the X45 torch as you only have a 1.0mm/50 amp tip to run at 30 amps.

I believe I figured out that it is the swirl ring. I rotated it 180 degrees and the dross is heavy on the other side now. Ordering a new one now!

1 Like