Thanks so much for the responses concerning torch height. I have used the numbers

Z0 for IHS Springback

Z3.81 for pierce height

Z.68 for torch height

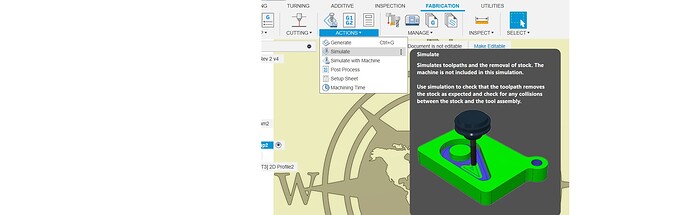

I have created a simple 2D circle profile in Solidworks and exported it to fusion 360 as a dxf file. Using these numbers in the gcode program - When I run this program. I get a cut (hole burned) when the torch first lowers to the material and then a torch fire at each 30 degree (estimated) travel around the circle. Is the problem in my dxf file or some setting(s) in the FireControl software?