I bought the crossfire pro as a hobby garage / side hustle…. But I have only cut ONE file I got off fire share because it is one single small cut a THUNDERBOLT I don’t know why I keep getting error code F07 on my titanium 65 I’ve rewired checked and replaced consumables!!! It will only cut a single drop line not multiple up and down or pause and cut not sure if I’m explaining correctly…… but I am very frustrated… let not even get started on my cad skills ![]()

![]()

![]() I feel like I bit off more than I can chew and made a $5,500 investment foolishly…

I feel like I bit off more than I can chew and made a $5,500 investment foolishly…

Can you share what was the reason for rewiring anything?

I ask because it can help us help you diagnose your machine.

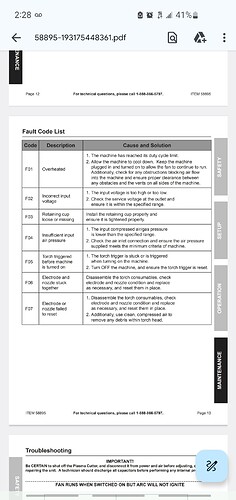

Based on the error here in the manual, it seems to be related to the consumables, which is why I ask about the need to rewire anything?

What are your settings for these cuts? Too long of a pierce delay, too low of a pierce cut, etc can all easily damage an electrode which would warrant replacing just as the error code suggests.

Please provide pictures of the consumables you had to replace, as well as your air supply, settings used, pretty much all information we would ask of you that’s missing here.

So you are saying “the torch touches down, lifts up, fires and cuts a “contour” and then the torch lifts up and moves to another location and …”

Can you complete the above sentence?

Does it throw the error after it touches down a second time? or does it not even get a chance to touch down again?

Another topic: consumables. Show us how the torch is stacked with your consumables. You may not have the ability to upload a photo yet but you will be able to soon. Keep responding to our questions and it will open up for you.

And Welcome to the forum!

post your gcode also helps.

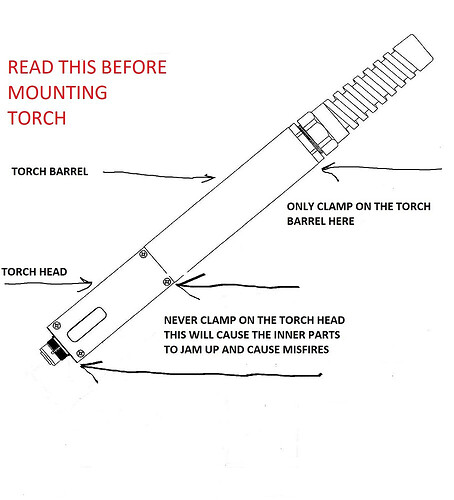

That is sounding like maybe the torch is clamped wrong? Hand torch or machine torch?

I’m not sure why I can’t post pics on here… I think the spring can be stuck but I’m not sure how to repair or replace that…. I’m running a 30 gallon (I know 60+ is way better and will be getting it soon) compressor which throws 6.5cfm at 90 psi with a 3 stage decassant filter (also know I need a dryer will also purchase soon)……

Yes sorry was frustrated and late night post… after first contour cut and it touches back down for the second it makes a popping noise and does not fire and throws the code……

If it fires the first time, the spring isn’t stuck.

What is your air pressure when the air is flowing?

If there isn’t enough air pressure, it won’t blow back the electrode to initiate the arc.

You need to have 10 posts before you can post pictures.

You may also need a longer pierce delay (.6). Most common failure of second cut in the same program is too short a pierce delay.

I move the pierce delay on the fire control on the +/- percentage if it’s a downloaded file when I download a file with its own settings I’ll put it in there…… I’m a beginner at this and a decent welder… I really want to cut out collapsible grills and make custom fire pits , smudge pots etc…… not sure if anyone has files for sale or specs?

We started a topic sharing some camp stoves a while ago. There may be something interesting there for you.

I’m actually right in the middle of making a collapsible new stove design. I’ve been printing scale models on the 3D printer to check my interlocking parts before I cut one out of stainless or steel

It’s the one the machine came with, how would it be clamped wrong? I don’t tighten too tight not sure how high or low the l bracket is really supposed to be!?

Also forgot to mention on the THC test of the live voltage out of 5 times I do it it only fires the full 3 times 3 out of the 5 the other 2 times it throws the f07 code on the second fire……

THC does not fire the torch…

It’s about where you place the torch within the clamping jaws. It can restrict movement of the nozzle/electrode if clamped too low.

I have a regular hand torch??? So where would I clamp?

I’m talking about the live voltage test…. Again I am 100% new to this…. Sorry if I do not know terms or what some functions do… ![]()