Got my cross fire setup and ready, but I cannot do anything with fusion, I have 12-15 hours in trying to make it work, and never getting close to making it work.

It just is not clicking for me.

Much of the problem seems to be that my screen does not look like any of the tutorial screens, I don’t have “model”, “ plasma” “cM” buttons,

So, what can I use to do a design, and save in dpf, then G code, and move to machine.

inkscape (free) and sheetcam ($150)… worth the money though.

Not sure what tutorials you have been looking at, but I’d recommend Lars’s videos on YouTube at https://www.youtube.com/user/cadcamstuff. He has some good beginners tutorials and they helped me alot get going. There are also many other good tutorials on YouTube that may help with a little searching. A workflow that I’ve been taking advantage of is that once you have your sketch in F360, you can export to DFX format and use Sheetcam to generate the gcode, which I find a little easier to use than the CAM in Fusion, but F360 can do this as well. Hope that helps a little…

James5. It would have to be easier, I do not even have a “cam” button

Does the Fusion 360 cam not work? I see sheetcam mentioned a lot

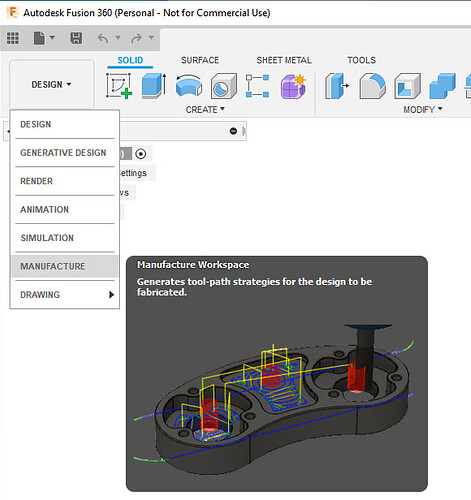

Fusion updated its UI last year.

Once you are ready to program your part, you want to enter the manufacturing workspace. Then click on the fabrication tab. Click on the setup icon to create your setup folder, setup your workspace, and origin.

You only have one toolpath funtion to pick from, called 2d profile under the cutting tool.

Sorry - should have been clearer - it’s call Manufacture now. This is where you tell the program how to ‘cut’ your design. It’s also used for making 3d parts in mills and lathes and other devices, so it’s got alot going on - but it’s not too bad getting a path setup for plasma. I’m pretty new to it as well.

F360 cam works well, but it can get pretty in depth. It’s designed for 3d models - our stuff is 2d flat cutting, so as long as you don’t get tripped up on the 3d stuff, you should be fine in either F360 or SheetCam. Sheetcam is a little more ‘purpose built’ for plasma cutting IMHO - it’s a little dated from a user interface perspective, but it works and is functional.

My problem/advantage…whichever it really is  depends on how you look at it. I come from cnc mill, lathe, wire edm side.

depends on how you look at it. I come from cnc mill, lathe, wire edm side.

I think all I need to do luckily is figure out which plasma specific gcodes I need and build a post for my cad/cam around it. Learning new anything is going to be hard.

OP, sorry for hijack

Are there .pst for sheetcam that work for him?

I know there are posts for F360 and Sheetcam.

Been looking at the Langmuir Tutorials, but they may be outdated, because the buttons that Langmuir Tutorials show are not on my newly downloaded version.

ConFusion 360 can be just that. I feel for those who got it after they changed it so much. Once figured out its an amazing program.

Went with Inkscape to sheetcam, to Mach3, watched some tutorials, got the G code loaded, going to try it out in a few minutes.

I will figure ConFusion 360 out later. I think it will be handy later, although via cad interests me.

The sheet metal module is very useful if you make things you bend with a brake. I’ve got things where I can eliminate 60% of the welds by bending instead and Fusion takes care of calculating the bend radius & everything when it unfolds it for cutting path generation.

Try solid edge from Siemens. It’s a nice program

My friend uses this for his water jet system

I can understand your frustration!

F360 is a powerful program, I use it exclusively now, for all my manufacturing needs.

It’s the interface that sometimes is confusing, but once you understand the logic behind the different screens, you will appreciate its flexibility.

I have a Tormach 1100m mill, the Crossfire, and a CNC lathe and a CNC router.

What I really like about F360 is all the different post (machines) I can do with one program.

Like I said before the flow of the menus will become more apparent when you see how F360 does this, i was lost in the beginning also, where are all my icons to get started???

F360 really simply breaks this down by what you are doing to your project at the time needed to produce a part.

Design & Manufacture are the categories I use the most in F360, and you will toggle between the two often.

“Design” is for actually creating your project, just a simple 2D sketch of something, then extrude. (Turn it into a solid) it helps looking at your part before you plasma cut. Especially extruding to the thickness of your stock material that you are about to cut !

Then jump over to the manufacture menus, and click on the appropriate tab for your process.

From there, it is probably best to go thru the setup information that Langmuir provides, it can be a little overwhelming on how the “post processing” works ( machine setup for f360 to talk to the Langmuir controller)

It sounds overwhelming, but Langmuir and YouTube have pretty good videos on the subject.

I think it will be great once I get it figured out

Using Inkscape and sheetcam, but I will keep hacking away at Fusion. There is a lot of design power in that program.

I feel your pain “BUT” keep at it. Autodesk pushed a revision last year that changed the icons and renamed many of the functions. They are all there but don’t sync with many of the the training videos on tube and others. I am in the same boat as you… wading through all the software but I think I have the CAD and CAM portions mostly figured out. Keep in mind that Fusion 360 has some additional functions that are bad-ass. While I don’t have it figured out F-360 allows you to perform stress analysis on your designs. This is huge if you’re designing structural components and want to test them in software. Anyway, don’t throw in the towel just yet.