Ok everyone, I have/had been looking around for a bigger/better/more robust lathe for my “retirement shop”.

Now my “plan” is/was to buy the “big tools” while I am still “working for the Man” and I have been earnestly looking for the “Mac Daddy” lathe.

Well I got a little carried away at the last auction, (which is damn easy to do BTW) and this little fella “accidentally” got bought.

Ok, full disclosure: I am not sure/doubt if this will actually be my “forever lathe” as promised to Mrs. RWS, but it is probably the biggest one I could actually fit down the stairs.

Kinda like that 44 Magnum Henry rifle that was gonna be my “last gun”…but I digress…

I “guesstimate” that it weighs in at a “svelte” 1,000 lbs’ish

But first things first.

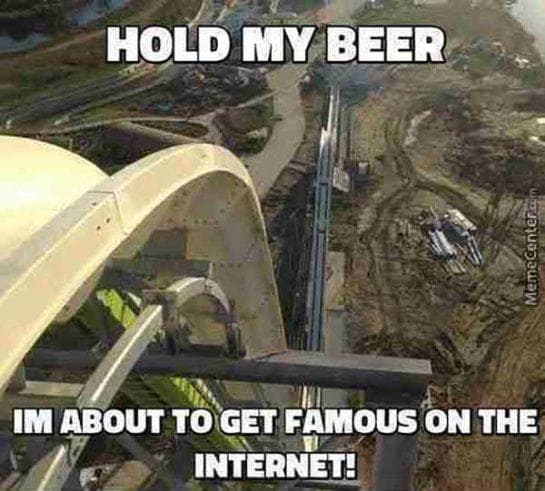

I am pretty sure my stairs could handle the weight, but this picture of me and my “new to me” lathe, crashing through the stairs and landing in a crumpled heap of blood and twisted metal kept flashing in my mind.

So I decided to “hedge my bets” and “shore up” the stairs.

Last time I did this (for my big safe) I used a series of 2x4’s cut and placed strategically. here is the area before.

instead of timber I decide to use my “hoist jack stands”.

But the small “footprint” is not sitting well in my already crowded mind…

Hmmmm…what to do?..what to do???

Ah ha!!! It’s off to the “newly organized” scrap pile…

And they they are…the remains of the “failed PHD stand”

This is will give me a “bigger footprint” but I am still not “lovin it”

I decide that they would be better employed on that middle “stringer” so off to the drill press to make some mounting holes.

Then I attach them to the middle “stringer” with som lag screws/bolts?

This gives me that “warm and fuzzy” feeling I was looking for.

After that, it’s out to the garage.

So I borrowed my BIL’s “cherry picker” to get it on the porch. (what an odd name…Cherry Picker)

then make a ramp to get it into the “foyer”