Since Fusion 360 update a few weeks ago, I cannot get my setup to run anything. If i load a previous file into Fire control, the machine works correctly. Fusion 360 added a bunch of new features and it seems to have made it more complicated.

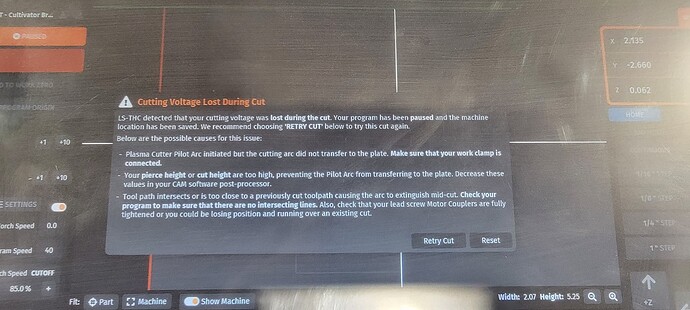

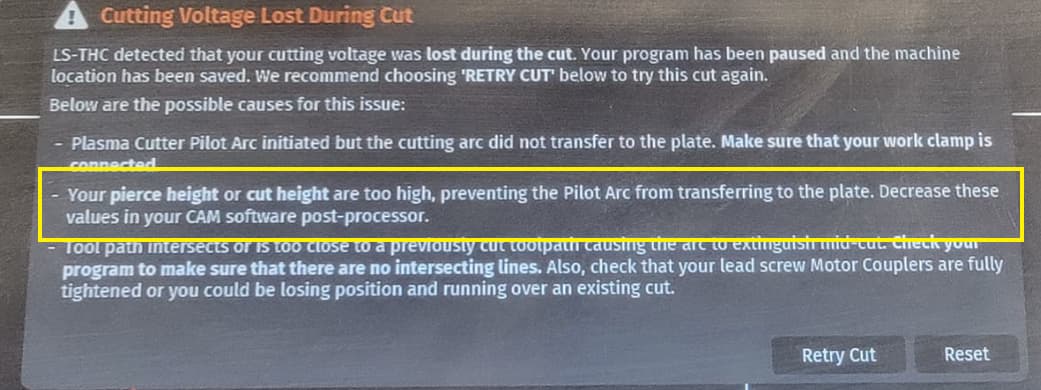

THC - Torch comes down, touches, moves up, fires and starts to cut and the torch turns off and the program continues to run. Sometimes ill get the voltage sense error and asks if i want to retry the cut.

Im using a Miller 875 with an XT60M machine torch for the last year or more with no issues until Fusion 360 updated.

Also, sometimes the THC control will drive the head into the part and on the screen it says down as it starts to drag the plate.

Lots of issues im trying to resolve since the update to Fusion 360.

Is anyone else having these issues? Is it possible for Langmuir to update the instructional videos on the correct way to set up Fusion now with the new options and settings?

Thanks

Post your F3D and maybe we can isolate the problem.

Yes between Windows updates and fusion updates there has been some issues over the last few months.

It seems like it only affects certain computers with certain versions of Windows 10 and certain gpus and CPUs.

I have one slightly older machine I run Windows 10 on and fusion 360 and I have a brand new machine with Windows 11 and f360 but no problems to report

1 Like

here is an example of it trying to cut a circle with multiple attempts to retry the cut. Starts the leadin the quits firing.

says i cannot upload attachments as im a new user…

Comment on other few posts and it’ll unlock that feature for you.

1 Like

It could just boil down to one incorrect setting in the new code can you copy and paste the first 50 lines from the Gcode you’re running as text and paste and posted here

v1.6-af)

(Machine)

( vendor: Autodesk)

( model: Miller Spectrum 875 Plasma Torch)

( description: Miller Spectrum 875 Plasma Torch)

G90 G94

G17

G20

H0

(2D Profile1)

G0 X4.1223 Y3.8425

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.12 (Pierce Height)

M3

G4 P0.75

G0 Z0.0625 (Cut Height)

H1

G1 X4.0614 Y3.6553 F40.

G3 X4.4519 Y4.0067 I0.1952 J0.1757 F40.

G3 X4.0614 Y3.6553 I-0.1952 J-0.1757

G1 X4.254 Y3.6962

H0

M5

G0 Z1.

G0 X4.1503 Y0.7519

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.12 (Pierce Height)

M3

G4 P0.75

G0 Z0.0625 (Cut Height)

H1

G1 X3.9972 Y0.6282 F40.

G3 X4.5161 Y0.7098 I0.2595 J0.0408

G3 X3.9972 Y0.6282 I-0.2595 J-0.0408

G1 X4.1809 Y0.5575

H0

M5

G0 Z1.

G0 X0.609 Y0.6805

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.12 (Pierce Height)

M3

G4 P0.75

G0 Z0.0625 (Cut Height)

H1

G1 X0.5481 Y0.4933 F40.

G3 X0.9386 Y0.8447 I0.1952 J0.1757

G3 X0.5481 Y0.4933 I-0.1952 J-0.1757

G1 X0.7407 Y0.5342

H0

M5

G0 Z1.

G0 X0.6292 Y3.7593

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.12 (Pierce Height)

M3

G4 P0.75

G0 Z0.0625 (Cut Height)

H1

G1 X0.6933 Y3.5732 F40.

G3 X0.7934 Y4.0888 I0.05 J0.2578

G3 X0.6933 Y3.5732 I-0.05 J-0.2578

G1 X0.8224 Y3.7218

H0

M5

G0 Z1.

G0 X0.0984 Y-0.2078

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.12 (Pierce Height)

M3

G4 P0.75

G0 Z0.0625 (Cut Height)

H1

G1 X0. Y-0.0373 F40.

G1 X-0.0373

G1 Y4.5

G1 Y4.5373

G1 X5.

G1 X5.0374

G1 Y-0.0373

G1 X0.

G1 X-0.0984 Y-0.2078

H0

M5

G0 Z1.

M30

(PS40)

is there a set water level that’s supposed to be in the table? could to much water cause the voltage or arc to loose its sense?

The latest issue i just tried right now - Cut 2 holes that look like shit and started the line and arc voltage lost then those errors came up. (3/8 plate. 40ipm, .0625 cut height, .1 pierce height.

Nothing jumps out at me in the code.

What’s the current condition of your consumables?

new- i already tried that… lol

What is the thickness of the material you’re cutting?

And you have your work (ground) clamp directly on the material?

Is your air pressure keeping up?

Can you run a straight line cutting operation through fire control successfully?

Doing that would rule out whether it’s from Fusion 360 or not.

1 Like

Have you investigated this possibility?

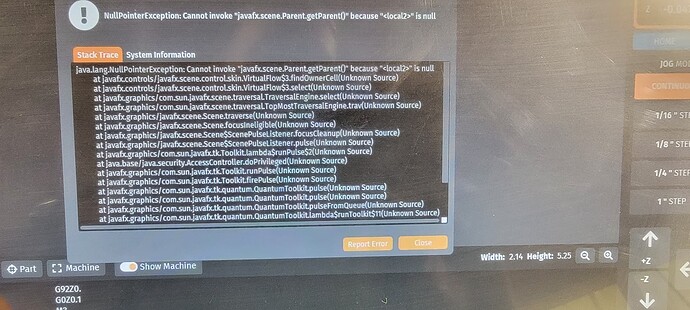

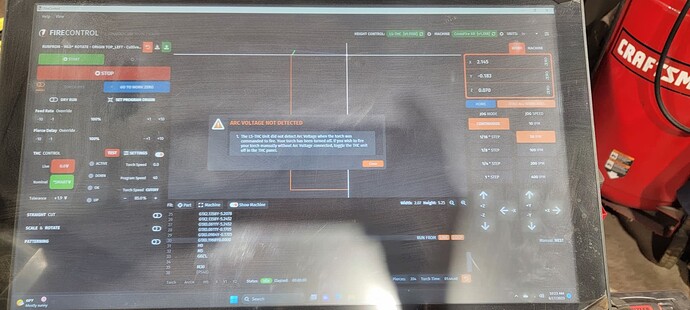

ha … another weird thing that’s

happening right now. sitting here not cutting just in “idle” this comes up on the screen:

no i can not. it runs about 1 inch and cuts off.

have you ever figured this issue out? we are having the same problem with “arc voltage not detected”

running miller 875 autoline