Hi I’m having some trouble guess I should have paid attention in computer class! Lol! First off I can’t seem to get my plasma cutter into the tool library in fusion?? Seems to be different software from what’s in the tutorial video for Langmuir? Next thing does the fire control need the internet to work?? I believe I have my hypertherm XP 45 hooked up correctly with the cable that’s available, THC is not connected in fire control and yes I have cpc port and mechanized torch?? I know it’s probably something simple but everything is supposed to be plug and play not so much here in CT Bergrider out! Thanks!

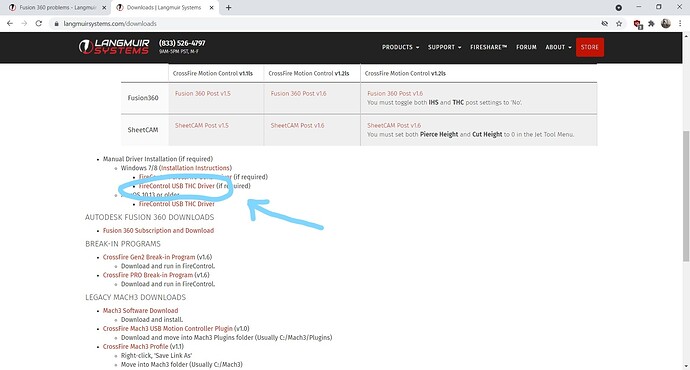

Install the THC driver from the Langmuir downloads page. The instructions really need to be changed, because it doesn’t install automatically in Windows 10 machines most of the time. The Green THC box in Firecontrol only means that the program can communicate with the THC board in the control box, through the USB cable. It doesn’t have anything to do with the THC being wired correctly.

No, the computer running the table does not have to be connected to the internet.

I don’t use Fusion, so I can’t help with that issue.

Ok thanks I forgot to ask does the plasma cutter have to be plugged in to trial run everything before I actually cut anything? I was thinking I could trial run everything before I go hot with the cutter

You can do a dry run without the cutter. Just toggle on the “dry run” button in Firecontrol. You must be connected to the table for Firecontrol to work.

Yes I can jog the machine XY and Z it’ just says THC isn’t connected?? Can’t put in any heights in for torch pierce or lead in and out? Not sure if the thc board is bad or something else is going on?

The THC connection has nothing to do with you being able to put in a pierce height or lead in/out. Those things happen in your tool setup in CAM.

If you are not showing a THC connection, it is because the THC module isn’t installed in the control box or you don’t have the driver installed in your computer. The most common cause is the THC driver is not installed in the computer.

The Z axis will work without the torch height controller. You can run the pro table with no torch height control and it will still use the Initial Height Sensing to lower down and sense the material height, then rise up to pierce height, pierce and lower to cut height. The only thing the torch height control does is read live cutting voltage and vary the torch height to stay the set distance from the material, if the material is warped.

Thank you sir I will check it out later tonight thank you

Do you think sheet am is easier to use than fusion ??

I do think that Sheetcam is far easier to learn and use than Fusion360 for creating toolpaths, but that is all Sheetcam is used for. You still need a design program to create and modify drawings. Fusion is an awesome design program, but parametric modeling is a steep learning curve and any program that uses sketches to model will require you to understand the basics of sketches and constraints.

I use FreeCad to do accurately dimensioned parts and Inkscape for art and lettering. FreeCad is not really any easier to learn than Fusion, as far as creating sketches and constraining them.

YouTube is a great resource to learn these things. Joko Engineering has some very good videos on learning the basics of FreeCad and several other modeling programs. Logos by Nick has videos on just about every aspect of using Inkscape.

This is my workflow:

- Design in FreeCad or Inkscape and export as a DXF or SVG file.

- Import that DXF or SVG file into Sheetcam, create a toolpath and post process into a .tap file. (once you have your tools set up for various metal thicknesses, this takes less than a minute)

- Import the .tap file into Firecontrol and cut.

Thank you for your time