I don t believe I ever encouraged you to use Fusion’s CAM. Fusion CAM has worked for me, I do like to keep everything in the Fusion Ecosystem.

While the existing post does not add the specific tool descriptions it does have two other locations where descriptions can to added, at the start of every new tool path and at the top of the g code general notes can be added.

Those can be add to the profile menu and natively forward along

I like this added reminder

This is interesting. The only time I have ever seen the plunge rate cause issues is with the default of 3.947 ipm in sheetcCAM being too slow. The default in Fusion of 100 ipm in fusion for the move of .09 in (.15-.06). With the time it take get up to speed I wonder if it even gets to 100ipm in the short length. The acceleration speed of the motor likely puts a cap of the actual speed of the plunge rate can achieve. The100 ipm default in fusion has never been a factor for me.

I’ll have to consider the reasoning behind modifying the feed rate to the lead in and lead out ?

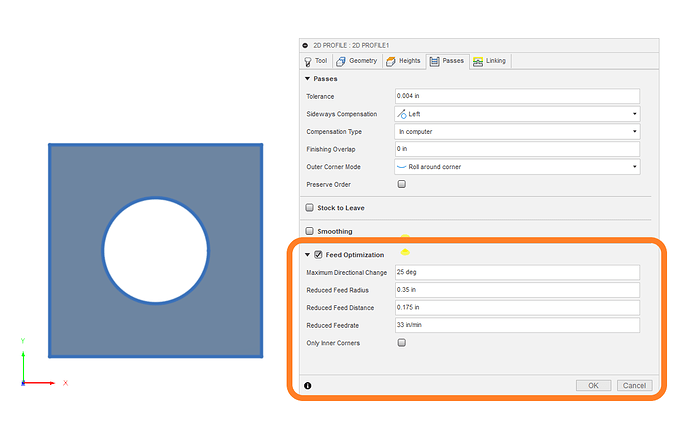

but as far as cutting feed rate modifying some options exist in the 2d profile menu under " feed rate optimization "

One of the options I have been hoping for in a future fusion update.

BTW to everyone, this is where feature requests are made to fusion so the more people that request the more likely it will happen.

In the meanwhile this post processor works great for center marks in Fusion

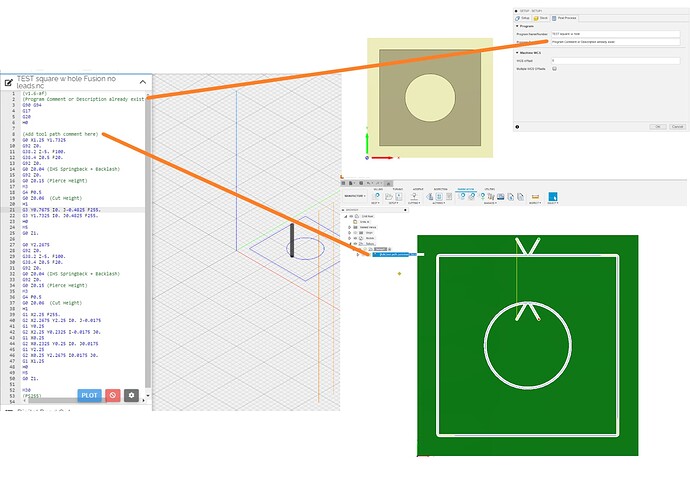

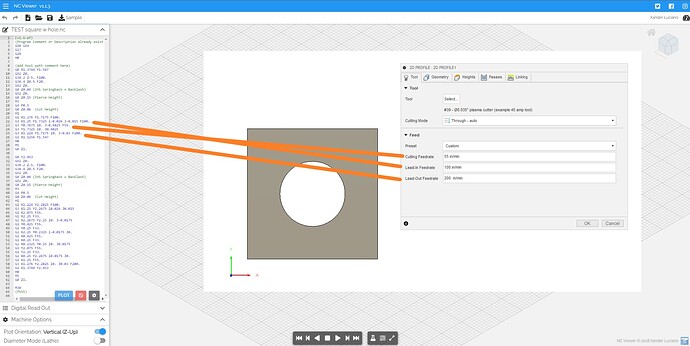

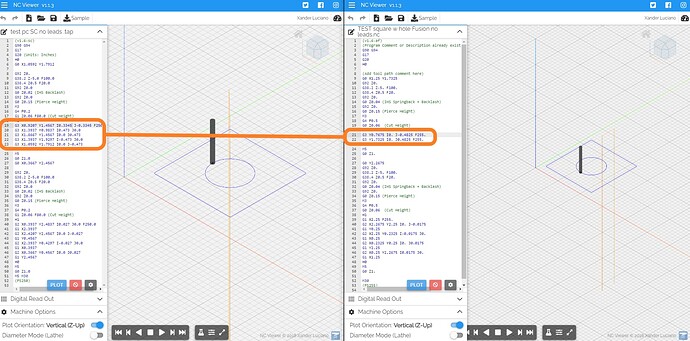

Here is a comparison of a test coupon, The left is SheetCAM the Right is Fusion. The highlighted section is the circle. Looks like fusion needs 60% less code to do the same circle . no leads.

I have limited experience with modifying the post processor but I’ll definitely be investigating the links provided . thank you.