Hey guys, this is my first forum post so apologies if it’s a little long or unclear. I have been having trouble with Fusion360 when it comes to generating a tool path for small holes. I have had my Crossfire XR for over a year and have been loving it, but the past few months have been extremely frustrating when it comes to small holes. When trying to generate a cut program, it generates as expected, but skips over holes smaller than 1/2 inch. I get the following error from Fusion360: Feature flags: inspection-in-pim (off) mfg-task-terminate-crashfix setup-sheet-viewer tool-library-v4-vendor-libraries

Does anyone have any suggestions? I’ve heard different things about lead in sizes and kerf widths, but all of last year I have cut similar parts and even smaller holes without any issue. I haven’t adjusted any of the tool settings, so I am confused as to why Fusion360 has all of a sudden decided to not generate small holes. Any help is appreciated!

@BeyondWelding13 welcome to The forum

Fread this post and see if it satisfies some of your questions.

@BeyondWelding13 I did some more research.

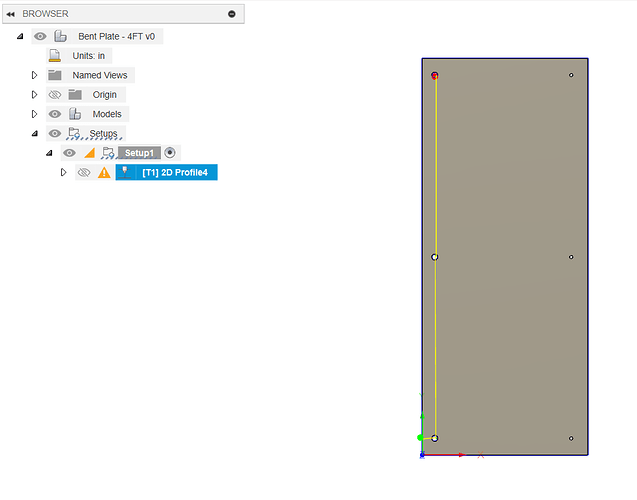

Try in the 2d profile menu to change “Outer corner mode” to roll around corner.

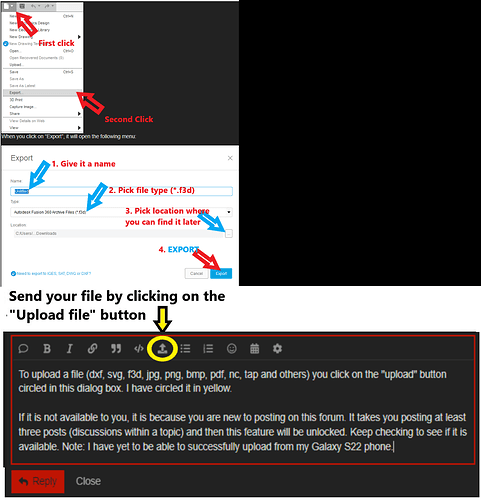

My account is still too new to upload any files, apparently. Once I am allowed, I will upload the file here so people can check it out. Thanks for the instructions though!

It looks like that option is already selected. I read that suggestion on a different site but unfortunately it didn’t help. I will keep searching through your videos to see if you have answered this problem already. I appreciate your help!

Go into your linking tab and check to see what your lead in length is. if you are in millimeters the default lead in length is 5mm reduce that length until the small holes are in the toolpath

Hey all,

I was finally able to get this problem solved. In the linking tab, I reduced my lead in distance as well as my pierce clearance a considerable amount, and it seemed to have fixed my problem. Thanks for all of your suggestions!