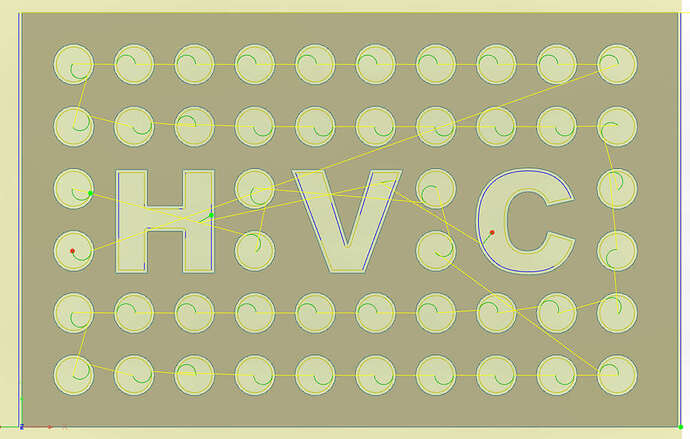

so, a few questions for those that have experimented or know better than i about the choices when setting a CAM 2D cutting profile, especially on thicker metals where the settings seem way more critical to getting a nice square cut. the first 3 tabs in the pop-up menu i think i got a good understanding of, they being Tool, Geometry and Heights… its the next couple that i have questions about.

- in the Passes tab:

a) what do you set the “tolerance” at, and how does changing this affect the cut?

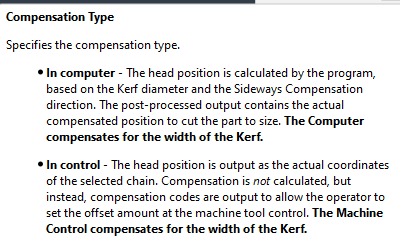

b)does setting the “Compensation Type” affect cuts

c) how much “Finishing Overlap” do you set? if you are cutting smaller bolt holes, is there a sweet spot to get the most circular hole possible?

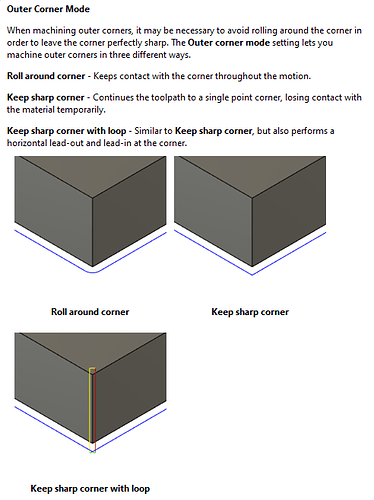

d) what do you set the “Outer Corner Mode” to?

e) do you select “Smoothing Tolerance” and if so, what measurement to you enter?

f) does selecting “Feed Optimization” make for better cuts, does it affect bolt holes, if you select it, what settings do you enter or how do you calculate what settings to enter?

2)in the “Linking” tab:

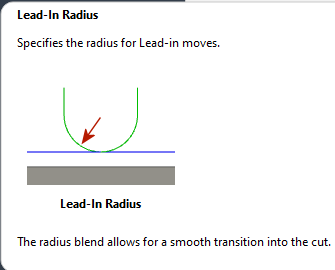

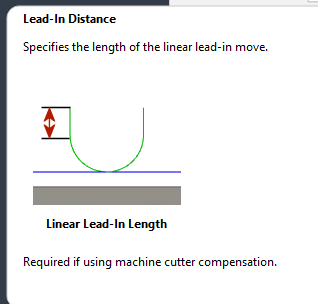

a)what “lead in radius” measurement do you enter?

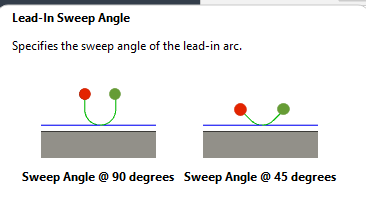

b)what “lead in sweep angle” works best

c)what “pierce clearance” do you set it at for the Razorweld 45?

d) what do you set the “lead out” and “same as lead in”?

thank you to all.