You’re not going to be happy here and it will leave a bad taste in your mouth about the machine and machining in general. Hammer the concrete out and do it right - for the next guy you may sell it to, anyway. In a month from now you’ll be no worse off and have a better machine.

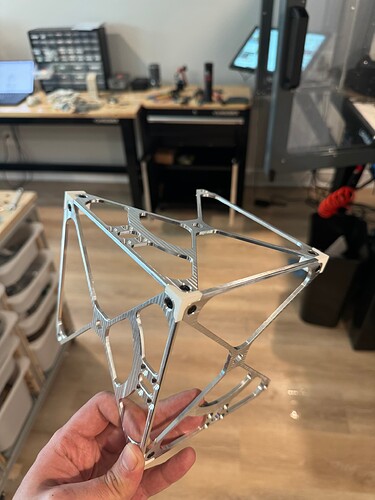

I truly respect all your opinions and I’m sure that I won’t have a machine with a performance that I paid for but “with that being said” I already completed building the machine last night, faced the build plate and it’s smooth like silk. I’m sure that doesn’t mean anything but I will be still happy to build stuff with it. If something catastrophic happens I will always have the chance to redo the base, even with some better options I saw in the forums. My first project will be building this thing out of steel and aluminum GitHub - willem-pennings/balancing-cube: A cube that balances itself in a corner or edge using reaction wheels . I will start posting my progress in the projects forum.

As a fan of a mid major basketball program who just lost their coach to 2x his salary at a bigger school…. This is triggering my PTSD from all the posts from players entering the portal chasing more NIL money. ![]()

![]()

Then you should definitely not watch the mr-1 assembly tutorial videos ![]()

Facing the built plate is a low MRR operation and doesn’t require a lot of rigidity, so I’m not surprised that it worked well. If you are okay babying the machine (a totally reasonable thing to do) then you’ll probably be okay. It will be interesting to see what harder cuts look like in practice for you, I’d like to see the finish that you get from something like 1/4" 4fl endmill in steel with 0.050" width of cut and 0.5" depth of cut.

I mostly do one-off work with my MR-1 and often run it below it’s MRR capabilities because time to finish isn’t that critical. I push the machine harder if I’m working on many of the same object and take the time to optimize my process.

Another way to look at it is that you probably downgraded the machine to something more like an Avid Benchtop Pro or another low-mass gantry mill that can do okay on aluminum but might struggle in steel.

I’m waiting the delivery for some bits to start the project I mentioned before (self balancing cube). It will have both 304 and 6061 pieces. I’m sure that I won’t have the chance to push the machine to it’s limits, but that will be fine for me. I know that I made a dumb mistake forgetting the stiffeners and I’m also aware that I made a dumber decision by not starting over, but that’s fine for me.

That cube is an intense project. Intricate and thin. If you are not already an expert machinist (sort of apparent given such disregard for the importance of stiffness and vibration dampening), I would recommend starting out with something less intricate and less expensive.

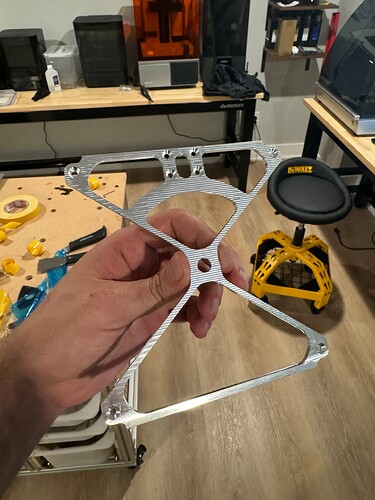

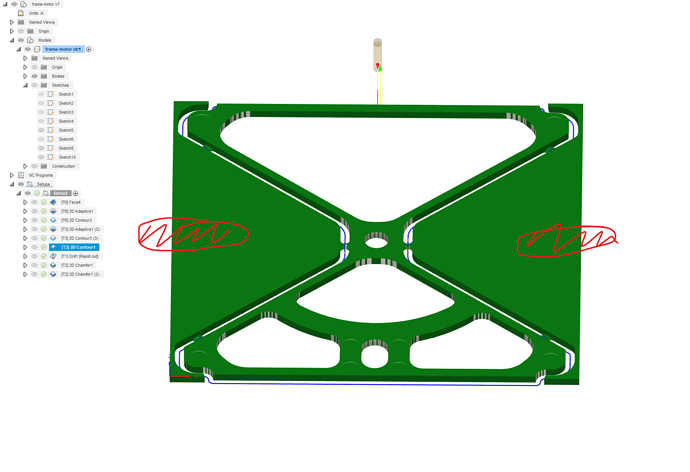

I’m a total newbie, but I believe it will be a great project to learn things. I started with the aluminum parts and I might use 303 instead of 304 for the steel parts. Aluminum parts are going well for now.

Nice! If you don’t mind me asking, how did you fixture those? Certainly those weren’t mounted up in a standard vise.

I clamped it to the baseplate on top of a scrap sheet at the red spots and used triangle tabs on the outer slot cut

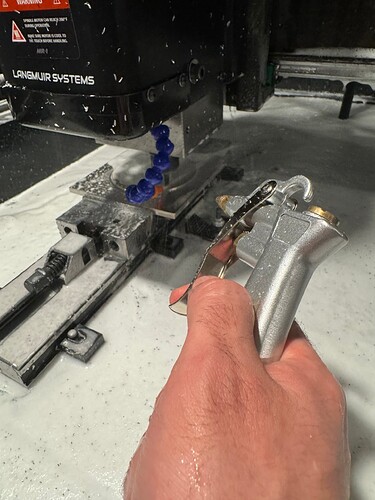

That’s also a perfect part for double sided tape or the blue tape/superglue trick.

I initially tried with double sided tape to speed things up but the coolant caused the tapes come loose. I never tried the superglue method and will definitely try it next time. Also for some reason my coolant become completely foamy just after a few hours and I don’t understand why.

Also, 303 stainless is the way to go. It machines so much more easily than 304. 304 has slightly better stainless qualities, but it still isn’t great…

I gotta hand it to you. You seem to be making limeade out of limes. Each step of adversity and you push on. I have been watching your thread to see how things work out. You are a renegade sir. Keep it up.

One question: Is that profile picture you? If not does it have some significance?

…just curious.

Hey, you made my day thanks! I got ADHD which makes me do silly mistakes, together with my absolute laziness, I have to create alternative solutions ![]() That profile picture is me taken 15 years ago

That profile picture is me taken 15 years ago ![]()

Btw I just started milling the first 303 part and the machine is cutting it like a butter ![]() The main problem I should be solving right now is understanding why this coolant become so foamy in such a short time.

The main problem I should be solving right now is understanding why this coolant become so foamy in such a short time.

What coolant is that? It looks like typical aeration. Do you have the hose tight on the barb, and the connection tight on your pump? If you are sucking air at that point, it will turn into a foamy mess with lots of coolants.

It’s fusion 2240 that came together with the coolant kit. I will check both right after the current operation. Thank you!

Any chance you cleaned part of the machine with soap that could have ended up in the coolant?