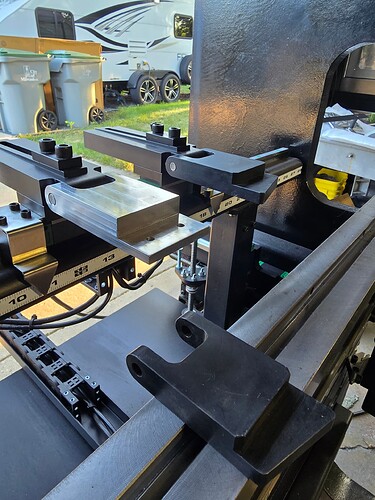

Almost have my flat fingers figured out. I wanted them to be direct replacements for the tapered stock ones. The second one was just a little out of spec for my liking so I’ll finish them up this weekend.

Looks nice. What’s your plan for the holes on the finger? Mounting point for other end shapes, or adding wear pads or something?

Yes they are for accessories. Mainly for a 1 inch flat bar to bridge the fingers. That way I don’t have to slide them back and forth to do multi step / tooling setups. Also going to make a set of thin extensions for getting real close to the tooling.

you could almost 3d print those with the right size reamer and some carbon fillament. fill a mint?

fil-a-ment like chik-fil-a?

That’s a legitimate idea right there. Probably don’t even need the reamer, and if you’re worried about the bores wearing you could press fit bronze bushings.

once I saw that pic I thought, this piece has zero use except to hold the part still that fraction of time before the press clamps down. so even if you had a crazy profile you could modify it accordingly to hold/locate the part. even create a back stop to hold it one position on one side for one bend and the other side for another bend. but I dont do this for a living so its just an idea.