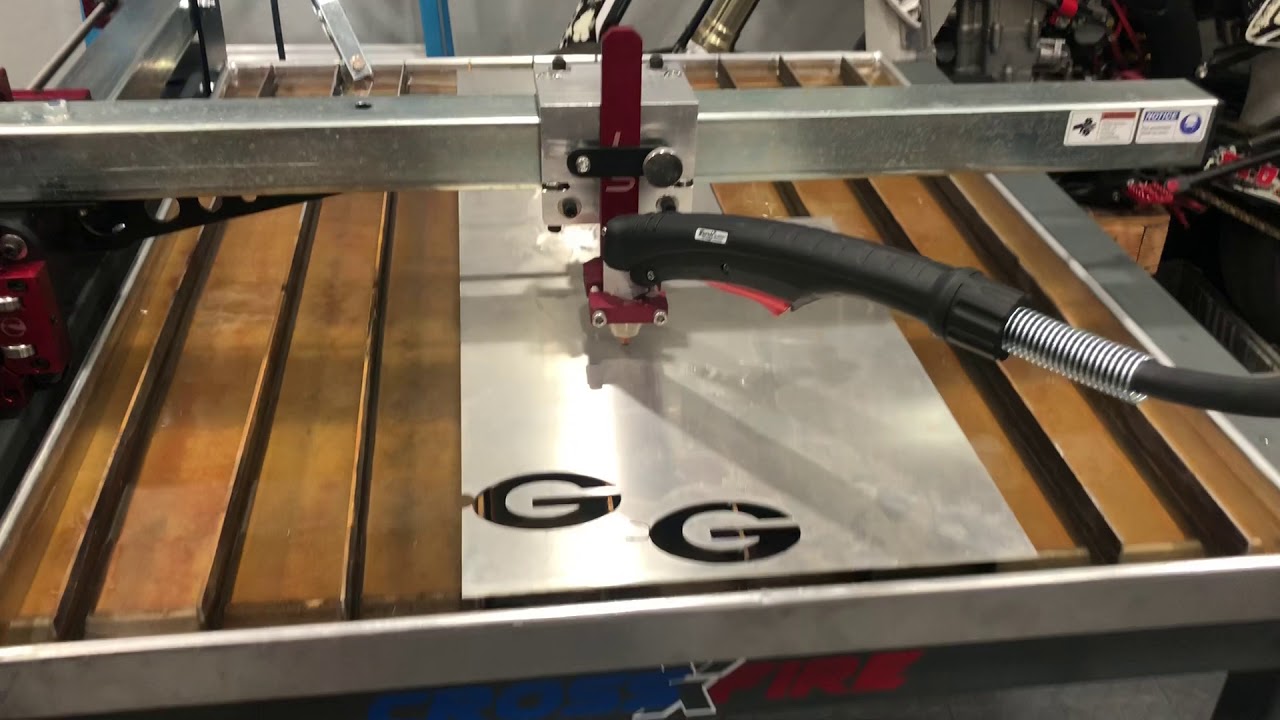

Wanted to start small so I cut out some 1” circles to finish a wine rack I started months ago. He’s a short video I posted on YouTube too.

Pretty neat wine rack design.

Thanks for the post.Cant wait!

Great job Brian- what material is that? The cut quality looks great in the picture.

Also, i cant tell from the video but are you using the ‘keep nozzle down’ function in Fusion 360? This arranges the toolpaths and rapid moves to avoid having the torch traverse across a previous cut section- thus minimizing the risk of colliding with a previous tipup.

If you’re needing more time to clear a tipup before the torch moves onto the next cut, there is a way to increase the delay in Mach 3. I’ll try to do a write up when i get some time.

You’re doing great! Excited to see what else you cut out.

No don’t think I did keep nozzle down was wondering why it kept jumping around so much. Had some issues with linking with this too. It wanted to cut the outsides before finishing the inside cuts.

did you upload that file from another program to make it a dxf file? Just curious how people are uploading logos, designs, etc…

This one I got the outline for the most part off a image online but all the inside work I mostly just free handed it in fusion 360 with circles and arc’s. I’m still very new to this and I am certain there’s got to be a better way to take stuff you see and import it into fusion 360 to cut. I have been trying to find a way to use adobe illustrator but am having some issues when it comes to cam tooling paths. Other people I think been using Inkscape but I haven’t really dug into trying that yet.

@bsulley22 very nice! the wine rack was a great idea. I’m super jelly, kI check my email a thousand times a day.

I suggest getting inkscape I’ve been playing around with it and so far have had pretty good success with tracing silhouette images off Google and adding texts that I convert to a svg image and then open in fusion 360. Plus there’s tons of tutorials on YouTube for inkscape

And Inkscape is free as well

Thanks for sharing your work. Do you mind sharing info on how you connected your 60i to the Langmuir system? I’m also getting the 60i and would be thankful for seeing what others have already done.

You can import graphics into Fusion 360 and trace those. When you import from an outside file format, you can end up with some weird lines that don’t connect the way you’d expect them to connect. When you draw it in Fusion 360 over an image that you bring in as a background on a face, your lines should all be nice and solid / contiguous.

Did you already order the thermal dynamics 60i? If you didn’t I would have to say pass on that machine it has a really annoying pre flow that delays the start of the arc. I have the Hypertherm 45xp and couldn’t be happier now

It’s already ordered. I wanted the higher cutting capacity. It was between the HyperTherm 60 or the Thermal Dynamics 60i. They both don’t have a CNC port unless you pay extra. The 60i has a few ways to tap into the start/stop signal and one of them might bypass that delay you’re talking about from what I’ve read. The HyperTherm 60 goes down to 20 amps. The 60i goes down to 10a, making it more versatile for me. I’ll deal with the delay in lead in offset. If I can bypass the delay by connecting directly to the control board inside, even better. Also there was about a $1100 or $1200 difference between them.

I would have loved to have both the 45 XP and the 60, but I don’t have an extra $4k burning a hole in my pocket.

Edit: I found out from Thermal Dynamics that they have an Automation Board Part# 9-8308 Available that adds the CNC port interface. Still would need to get a connector to plug into that, but I like the idea of having a factory designed CNC port instead of hacking together my own. (The schematic in the manual does give you some info on what signals are available straight from the control board even without the automation interface.)

I use Adobe Illustrator for all my designing and haven’t had any issues yet. You can export your art to .dxf files out of Illustrator and import those into Fusion 360. Hope this helps and let me know if you have any questions about the process.

If you could show me a walk-through of your process, I would be interested. I have been using adobe products for years and this would make things much easier for me.

Let me see if I can screen record my process later today and upload it to YouTube. I will post it here when completed.

id like to know were you read about tapping into other signal on control board

ill be running thermal dynamic 38 and im worry about the pre flow and delay

thanks

petr

I’m not sure if the 38 has the same kind of delays that the 60i does. The 38 has a very different control board. From looking at the schematic in the back of the 38 manual (available online: Do a google search for Thermal Dynamics 38 Manual, it should come up easily) it looks like you’d just have access to triggering the torch.

I contacted Thermal Dynamics to find out about an automation kit (P/N 9-8308) that they mention in the manual for the 60i. I ordered the part they told me which should arrive this week or next. I don’t think that they make an automation board for the 38. So that won’t be an option for you. I hate to say that you’ll just have to give it a try and see what the initial arc delay is, but that is likely the best bet.

Edit: Part number edited. Thermal Dynamics gave me the wrong part number. Now they say it is 9-8308 and I see someone else was given that same info from TD/ESAB as well.