really like your set up I have a Everlast 52i thinking about upgrading at some point but it seemed to do well with the 1/8" steel.

before I got into CNC 16 months ago…I had the old Everlast 50…I could punch through the side of railway track steel…

I ran that thing hard…and then sold it before getting the 62i for CNC fun…

That’s cool!

Yes its worked good so far. Call me crazy but I ordered I x45 machine torch for and need to rewire it. My father is a electrical guy so working with him on it. Any tips on rewiring the razor weld machine torch for the Everlast are welcome. Hope I didn’t make a mistake I just like the beefy consumables and heat sink on them.

Thank you sir!

Sorry No idea on that lol, still waiting on my razor to show up. Was thinking about buying the mount and the machine torch as well, but I think I’m going to run the handheld for a bit and see how it goes for awhile.

yes the handheld worked fine for my first signs.

The Everlast 52i is a good plasma cutter capable of 1/2" metal cutting. My choice would have been the PTM 60 machine torch so you can get a full range of consumables for doing different thicknesses of metal and get more detail.

A lot of people are falling for the hype being posted about the HYP45/X45 torch’s thinking they are and use Hypertherm consumables.

Just a note here: If you want to do all your cutting with just ONE set of consumables you can do it with all plasma cutters and torch’s made.

The X45 torches that come with Razorweld plasma cutter that we sell are compatible with and frankly perform the best when used with Hypertherm powermax consumables.

Then why does Langmuir not sell Hypertherm consumables for the X45 torch???

If I have ever posted anything on this forum that was not true or misleading, I would really like to know about it.

Also anyone that wants to contact me can call me 8am to 9pm est .

What about the clearance issues people spoke of in this post?

We do not sell them because we do not have a business relationship with Hypertherm. If we did we would. The ONLY reason we order Razorweld plasma cutters with the X45 torch is so that customers can go down to their LWS and buy genuine Hypertherm consumables. Sure we sell Razorweld branded consumables, but i have cried far and wide that they are not as good as Hypertherm. You can search my history here and on the FB groups, i only ever recommend Hypertherm consumables. The only reason that we sell the RW brand consumables is because they are a cheaper option. Our business thrives on people getting good cutting results, and that is easier to do with genuine Hypertherm consumables.

Daniel, I have been in the plasma cutting and welder businesses for around 35 years. I do not recommend to anyone to use consumables or parts on their plasma cutters or welders that are not what the company that makes them recommends or uses.

If you want to recommend Hypertherm consumables on the X45 torch even if Hypertherm does not recommend it then do so.

I will still recommend the Tecmo consumables because Tecmo made the original TH70 that has been renamed by Razorweld as a HYP45/X45 torch.

Lookin good keep up the good work.

Thank you very much for your help!

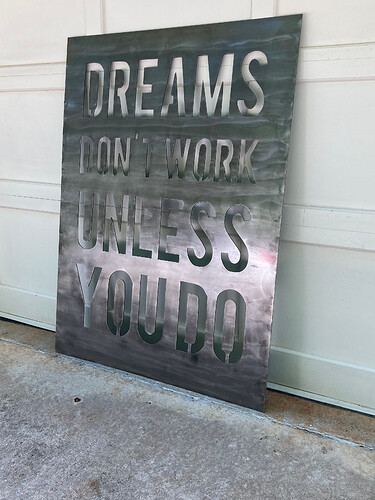

Experimenting with different metal finishes wondering if anyone had any tips. For example what do people use as clear coat that holds up outdoors. The finish I’ve been using is Penetrol.

reid913

Any tips on how you got that nice rust patina? Looks really good!

I have used auto grade clear coat on a lot of metal parts over the years (raw steel and painted) and also the high temp clear coat for engines with good success. I feel like giving it a prep wipe down with acetone or alcohol makes a big difference (assuming you don’t want rust that is).

When I use the high temp clear I throw it in my powder coat oven and bake it at 175 - 200 for 30 min or so and it seems to cure fast and hard.

Nice okay thank you very much! So my rusted patina has alot of copper in it. First I use a paint brush and apply muratic acid undiluted to my metal. And just keep applying till the mill scale is falling off. Then I rinse it off well with water and apply a mixture of muratic acid and coppersultfate and let sit for like 5 to 10 min. I also like to wear a respirator due to the fumes. I leave the acid copper solution on and then drizzle or drip hydrogen peroxide in different patterns on the metal usually letting it drip down hill. It only reacts with a certain amount so I keep dripping it on till im satisfied. and then rinse it with water. Sometimes dry with either a heat gun or a torch. But I try to put some sort of oil on it to keep it from oxidizing further. I have to do this quickly. Usually lineseed oil or something like that.