I am running a prime weld cut 60 on a crossfire pro table I did the hook up threw the cbc port 1&2 and 4&6 are the pins the manual told me to use the two white wires that come out of the port I was wondering what port I hook them two one the thc control box thanks any help would be appreciated don’t want to crash the machine on the first cut thanks

if you want reliability with this machine you will hook it up using the raw voltage installation.

Only use the CPC port for the trigger (fire) circuit.

PrimeWeld Raw Voltage Cable Installation.pdf (2.3 MB).

Check out this step by step guide.

The pigtails from this installation will hook to the “clamp” with the red lead and to “torch” with the black lead.

Then from the “PV OUTPUT” connection on the VIM ( voltage input module ) to the Langmuir electronics enclosure.

As @TinWhisperer has stated raw voltage from inside the plasma cutter works best.

If your using a hand torch with the air flowing set it from 65 to 70 psi, machine torch should be set from 70 to 75 psi and at least 30 seconds post flow.

Thanks for

The info and the instructions I will hook it

That way and try it glad this forum is here thanks again

The two white wires should go to pins 1&2 and plug into the control box where it says “torch on/off”.

That is what fires the torch.

You already have some guidance for the THC voltage wires.

As soon as I plug in the pv output the torch fires without even turning on the torch in fire control

Or enabling it bare with me iam new to

This

Wrong wire, pins 4 and 6, not pins 1 and 2.

1 and 2 go right into the front of the control box with the barrel plug. It says torch on/off.

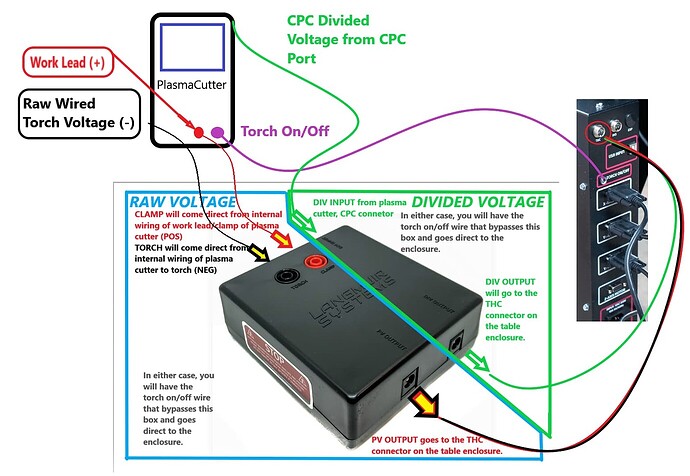

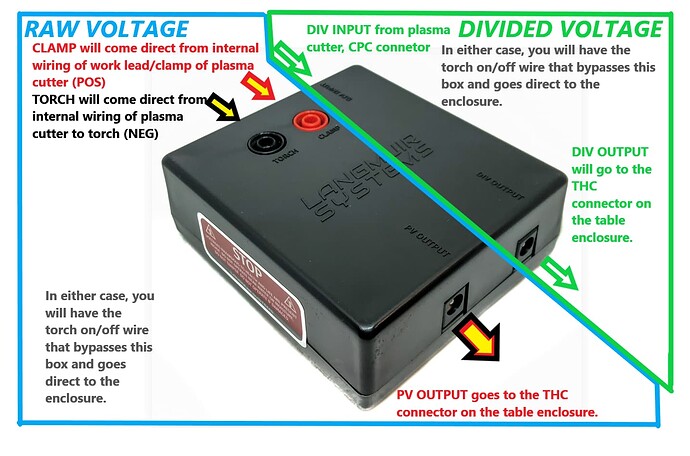

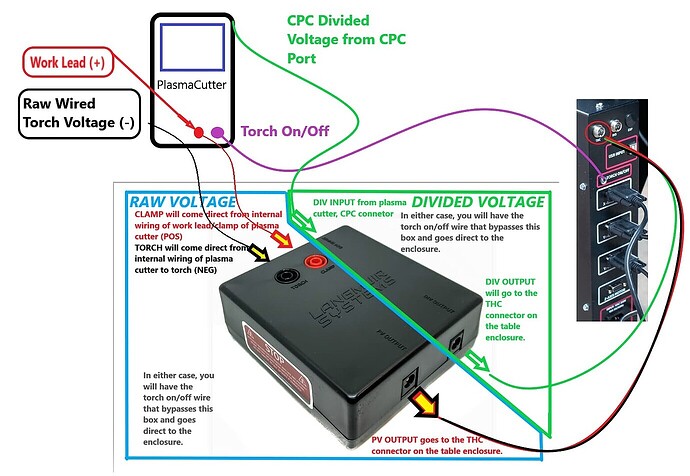

If you ran raw voltages, here is a diagram.

If you are still on divided voltage from the CNC port pins, follow the divided voltage illustration

I must ask if you have the red lead to the positive clamp? The black lead goes to the torch.

The black lead I hook to the torch side inside to plasma not threw the cnc port

And the red lead went to the ground side in side the plasma

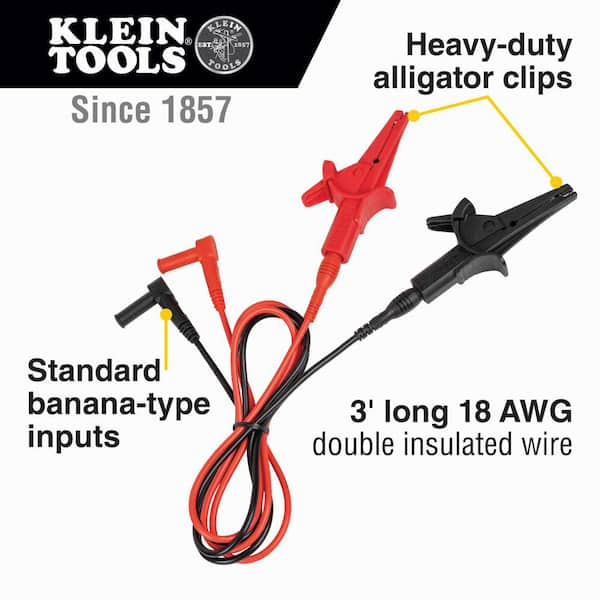

The clamp side is positive, and the torch is negative. But that’s good. Now, take the banana plug with the aircraft-style plug and plug it into the control box that says THC. Take the wires from pins 1 and 2 with the barrel plug into the control box that says torch on/off. Look at the illustration and make sure the banana plug is in the PV output slot on the VMI (black box). Not the Div output.

Then you’re plugging the wrong cable into the PV output.

The cable that is attached to pins 1&2 goes to the torch on /off port on the electronics enclosure that is bolted to the table leg.

Ok all go check I sure appreciate your help been welding and millwright work my whole life but not a wires or tech guy

Hopefully one more question I do have water in the pan but do I have to cut the end off the thc connection to hook the banana clip on to the thc original wire with the plug on one end and aircraft plug on the electronic enclosure

Think I have everything else changed just a little confused with the banana clip

You should have one already from Langmuir

These are the cables. Sorry mine has the banana plug but it looks like they changed the style. The one on the right goes from VMI box PV output. The one in the middle goes from your CNC port to the torch on/off on the control box.

Please use caution while the plasma cutter is operating not to touch those black and red wires from the inside of the plasma cutter.

If you connected to the torch and clamp inside the machine, you should have separate red and black wires. Those get plugged into the color matched ports on the face of the VIM( black plastic box). Then you need a cable from the PV output on the VIM to the THC port on the electronics enclosure.

No other ports on the VIM are used in this situation.

Got

It firing made a straight line cut for

Some reason the torch didn’t shut off at

The end of the cut tried it theee times

Same

Outcome but at least cutting thanks for the help

So far