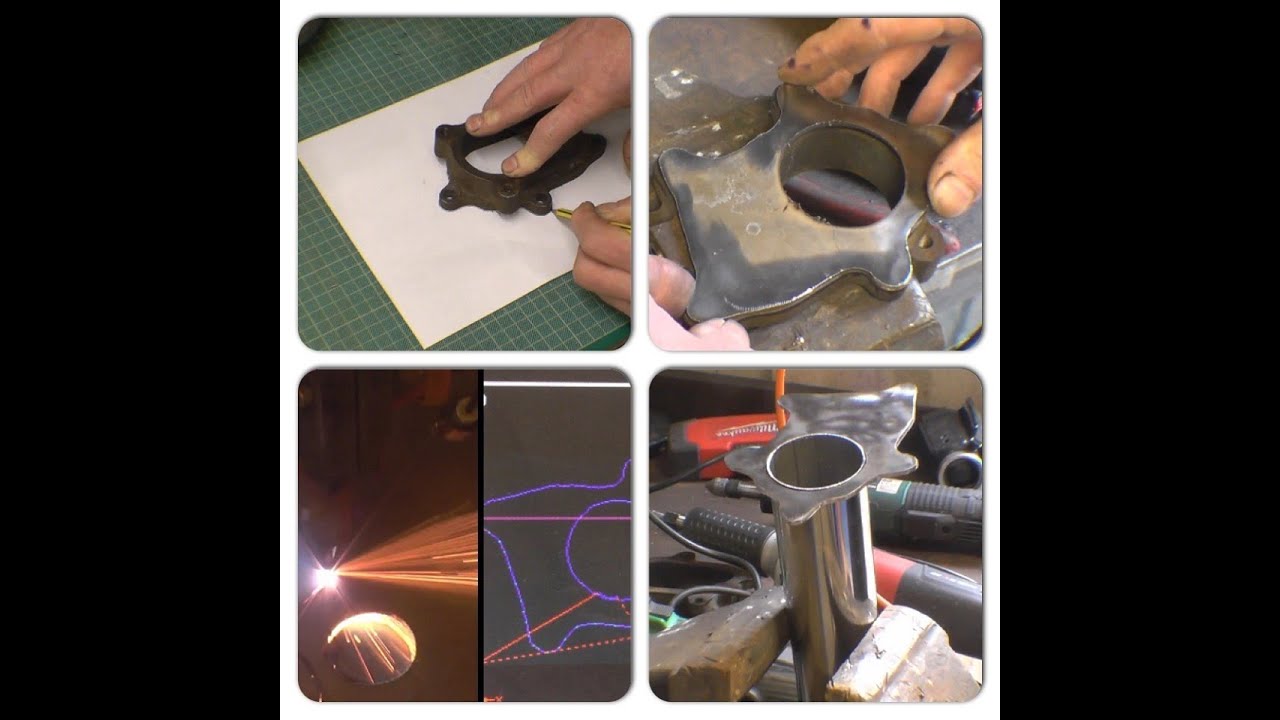

Are there any plans for a trace function in the works? Would be a great upgrade to fast track some of my custom non conforming brackets or duplicate my CAD (cardboard aided drafts). I could piece together the paper cut-outs and produce a one piece patch or unique nonlinear profile. Cad is great but sometimes pencil and paper fit the bill.

take a picture of your cardboard template next to a ruler and import into CAD of choice

this might also be an option

Yes I have done the photo copy and transfer method. Problem is at each step error is added. If the same hardware were to scan the item along with its eccentricities it would better represent what was intended with fewest tweaks needed. To elaborate, the same jagged curve would match the capability and resolution as the pro table. If the camera follows a path the torch could best repeat that path without extra accumulated error. I have seen doubleboost use the mach3 software and to be honest it’s still beta for sometime now. It is an option but having everything in one place even as like arclight a torch to camera swap and push a button. Sheetcam next is necessary but just putting it out there as a sales tool over the competition and the mach series.

I started watching those videos from doubleboost on YouTube, pretty cool.

I’ve used this method in fusion 360 but not really the same thing more just drafting over top of the picture.

if you have a scanner you can also use that. a 600dpi scan gets you a resolution of .002 which also happens to be the accuracy limit of the table

Yes, that is what I have been doing. Make my card board template, scan, stitch and splice. But I don’t want my fragile computer scanner in the plasma table environment, the barn. Also fabrication can be dirty and that’s the biggest issue. Will mach 3 or 4 work on our table? So could use scan anything .