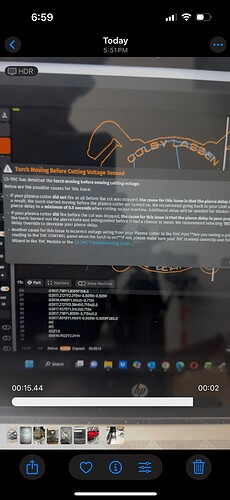

Any help here would be greatly appreciated. I’ve about had it haha. When running my cut in Firecontrol it will cut out a section fine and then pause and throw an error code saying “torch moving before cutting voltage sensed”. I then generate the next cut and it cuts out that part and then once again pauses with the error. Any thoughts? I’ve done the voltage test as well as messed with the pierce settings and get nowhere.

Did you follow the provided suggestion of increasing your pierce delay? The warning is trying to help.

What is your pierce delay anyway?

Pictures of consumables and torch mounting. Please confirm that the electrode can move freely up and snap down with your finger. You had that table a long time. Did this start with this design?

Started just recently after installing the THC. Has worked before but for some reason with this project it is struggling. Replaced the consumables last night thinking that could have been it with no luck. Also the consumable does plunge when pressing with a finger.

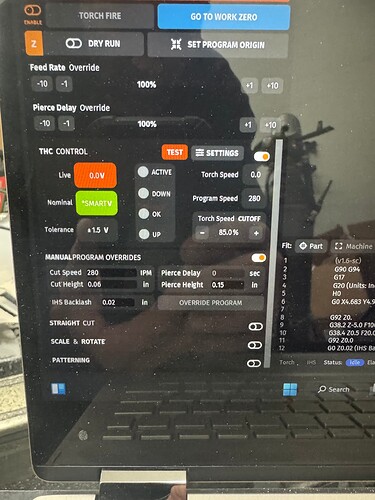

Those are your overrides.

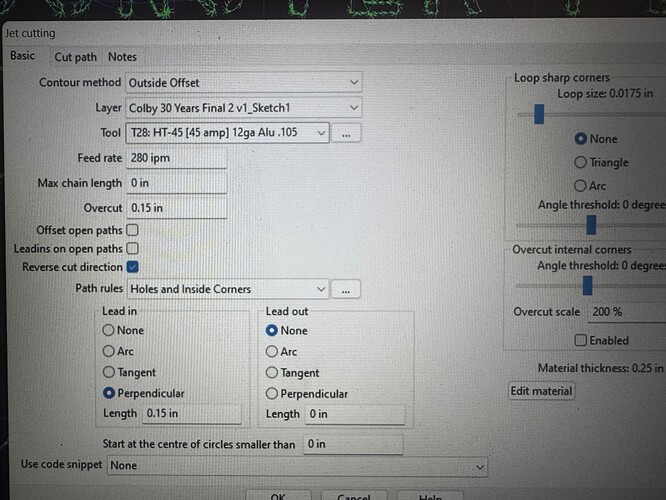

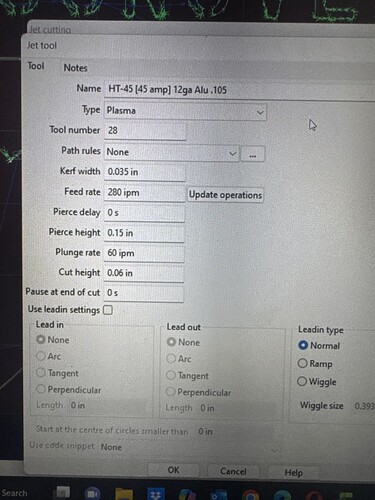

What are your settings, as in what are the values you input when you created your g-code whether it was Sheetcam or Fusion 360.

Also, that 0 second pierce delay immediately conflicts with the very warning you posted. The warning tells you to run a minimum of 0.5s and you did a manual override for 0.

These were just some settings I downloaded from a guy that posted his tools on this forum. I’ll post a pic of what sheetcam showed the settings. The zero pierce was grayed out in Firecontrol and it couldn’t be changed.

I’m unfamiliar with Sheetcam and don’t see your pierce delay in the phone picture you shared.

Where’s your pierce delay setting?

Pierce delay on this tool that I downloaded is a 0. I’ll try to manually make my own tool and see if it will change anything

Crossfire and crossfire pro you need at least a 0.5 pierce delay. Try adding a longer pierce delay first, if that dosent get you cutting we can work through it. That error just means that your torch isn’t staying lit. Fire control is expecting to read voltage for the torch height controller input and it isn’t getting voltage because your torch failed to transfer from the pilot arc to the cutting arc. FYI for future reference…. When you post a pic of your consumables take the pic from the top looking down into the orifice of the tip, and from the bottom looking up into the orifice. Remove the electrode from the tip and take a pic of the of the top of it.

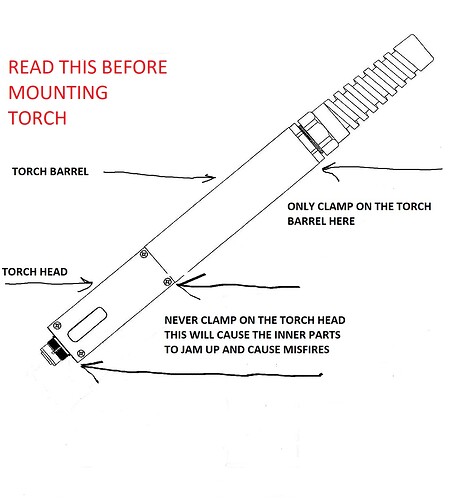

- Move the bottom clamp higher on your torch.

- 280 IPM is way too fast for .090 aluminum. It should be around 110 or so at 40 amps.

- You have no pierce delay. Set it to .5 or greater. I would use .7…

- I have zero experience with SheetCam so maybe someone can chime in.

- Put water in the table before you burn a hole in the pan.

- Make sure the work clamp is on the metal you’re cutting.

Everlast PowerPlasma 82i cut chart.pdf (47.1 KB)

This is for a Everlast but it should get you in the ballpark.

The zero pierce delay is definitely the problem here.

The Hypertherm chart that the tool originated from is based on a system that has feedback that tells it when voltage is received from the torch. The delay counter starts once voltage is sensed from the torch. In the case of a zero delay, it will begin to move once voltage is sensed.

Langmuir tables don’t use an “OK to move” signal from the plasma cutter. The delay starts the instant the signal to fire the torch is sent. Since it takes at least a few milliseconds for that signal to reach the relay on the control board, your torch is trying to move before the torch has fired. Time needs to be added to the Hypertherm chart delays, so that the torch will actually fire before trying to move.

For reasons unknown to me, Firecontrol always adds delay time to the first pierce. This is why people always have success with the first cut loop, but get an error on the next cut loop. Generating the cut again makes that next cut the first pierce in the program, so it works again for one cut loop.

Increase the delay and this problem will go away. You should always make your own tools based on testing.

Don’t worry about the torch mounting, The only moving part in a Hypertherm torch is the electrode itself. They are not like the Tecmo style torches that have an electrode that screws into a moving assembly that is part of the torch.

It was definitely the pierce delay. I was entering in .07 vs .7 thank you all for the help! Much appreciated!!!

‘Told ya so’