FC froze today, no motion errors but a freeze which killed about 20 minutes to save the material. Beyond annoyed with it. Not only did I wait for moooooonths and bank on this setup, now I have an extremely unreliable boat anchor, yeah I can limp by but I am limited to what I can do. Iv spent way too may times on here and the back and forth is just ridiculous. Not to mention wasted thousands of dollars. Im just highly regretting this decision dang near everyday I cut there is an issue.

We are working very hard to solve the issues you are seeing. Our development team is focused on replicating and finding fixes for these issues specifically. Due to their inconsistent occurrence we are taking extra precaution before releasing.

I sure hope so. Iv tried and tried to have patience and knew there would be some things that we might have to deal with. I like FC and wanted to give it as much feedback as I could, and did. But this is just too much. I really thought reading all they hype about the XR that it would be way better. FC desperately needs tested at your facility bf releasing. Do you guys have a machine cutting for hours a day with different cutters? No, so we have to and we have to deal with the problems. I like seeing other companies actually cut parts for their machines on their machines. I know some things need laser cut but that right there would give you guys an actual taste of production cutting in house to see what is going on.

Lastly, better communication with me and or customers would be great. I had no idea you guys were still working on what? Are you working on FC? I just don’t know if its FC or my control box, PC etc.

I know you guys are always working on FC and talked about a Cad duo (hope you don’t do that) but maybe just a thought, after all these updates and freezes, maybe try some new programmers or engineers to get this solved. Easier said than done I know, I always give you guys the benefit of the doubt.

I don’t want to complain on here and hope others that finally get setup can come on here and share issues (or lack of issues). I hope things go smoother for you guys in the future. You’v helped me grow my biz for sure, appreciate that, but as I said I gotta move on. I will be transitioning to other tables this year.

Outgrowing a machine is a really good story. I hope we get there too.

Cheers!

Well you would be a giant step ahead of us if you started with the XR. I started on batch one of the crossfire. I ran that sucker with no water table for 6 months using a hyp xp 30. Got a water table (I live in cold region) so that was one issue, upgraded to the xp 45, no THC was available yet. Had plenty of warped steel, tip ups, lead screw issues and the works! But I got my feet wet real fast, made a ton of money off that machine, bought a back up, used the gantry to update my first table. Hesitated on the PRO but eventually got it, had alot of FC issues, still had some lead screw issues, but eventually it worked pretty good. Bought another PRO so I could run back to back machines, built a bigger water table, I also raised the Rails up. The first PRO lasted about a year and I got really bad issues with the X asis to the point where I couldnt’ get good cuts for the life of me. So I setup my new PRO at my new building and ran it a couple months till I got the XR setup. So I been cutting with LM for 3 years and am on 5th table and my third hypertherm. Cutting production is just not easy no matter what. I expect some problems but others that can be avoided would be nice to not have. Its a learning curve for sure. I look back and see how far Iv come each year and am blown away with what Iv dealt with. Its like working on cars, you won’t learn until stuff breaks or won’t work! But running a biz and depending on equipment you just need reliability.

I also kept coming back to LM bc of this forum. I just didn’t trust some other companies out there. Some that I do have my eye on are really expensive and if I can’t test it out I sure as heck don’t want to have another boat anchor in my shop. I also didn’t want change from one system to another. I liked FC layout besides the issues, so I wanted all my tables to run one system. But even now with PRO to the XR I have to change all my pierce delays, so reprogram them and or change them manually each time I open a file, which is what Im doing now. So eventually I’ll have a folder with about 50 files that are all for the XR and my 65 amp plasma. The PRO will be running my 45 amp. Its nice to have a complete running backup. Very important with running a biz.

did you ever figure out if it was a post processor error? i generated a quick program in fusion just to compare. i still think that G1 F50.0 is funky… my NC files always show a direction after the H1 line not just a speed like yours is showing. curious if LS ever said anything about it. if you send me a DXF id be more than happy to run it thought Fusions post processor for you to see if you have any better outcome…

No word yet on the motion control errors. However I inquired a while back that I was still using the THC module from my PRO, well there is a difference in them. The status bar will actually say what version of the THC firmware and it will say XR. So today was first day I ran that. No motion control errors and no freezes.

I also like an idiot figured out (after being asked about it) I had my two chokes on the two usb cables going into the mini pc. well turns out its best to have the chokes on the computer to control box cord, one on each end. So between these two things, Im hoping that will be a big help. I will surely keep everyone posted.

I have been in personal contact with Mike one of the owners.

As for the post processing, I have sent them files that I posted and actual work files. I just don’t see how after years of using sheetcam with the same post processor that it would be an issue. I use to use fusion long time ago and if I recall it generated tons more lines of gcode than sheetcam. That was a pain to sift through using mach 3. I much prefer using sheetcam on all levels.

I made about 900 pierces today. No freezes or MC errors. I did have the Z axis hang up twice today where it woudl fire about an inch or so higher than the sheet. At first I thought it was a program issue, but it could very well have been something in the lead screw. So I blew all that out. Iv had this issue many times on the pro also. the z axis just gets gummed up, needs cleaned and oiled. So hoping thats all that was.

I also restarted FC a few times today, one of which when it opened it would not communicate with the control box, so I shut down FC and opened it back up and it communicated.

That is great news! Intermittent errors are the worst. Keep us posted - you’ve provided some really good data points.

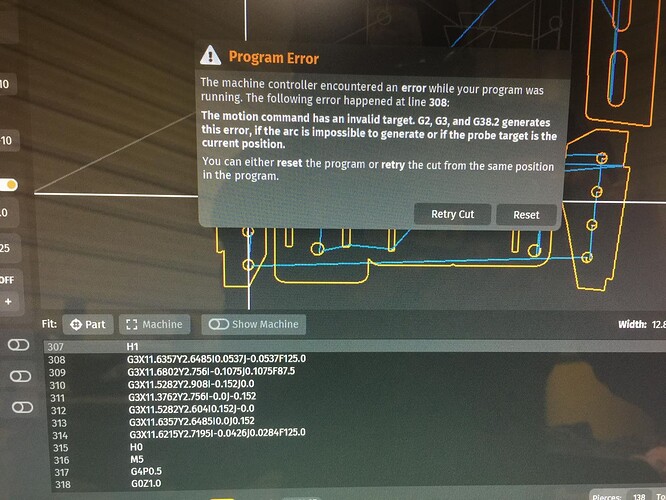

Well day next day cutting I ended up getting 3 motion control errors within about an hour of cutting, which is very rare. One of which was two holes back to back. Normally Id get one error I’d have to skip that hole and it would cut rest of file with no problems. Well this was the first time it had issues with two holes in one file. Thankfully no freezes but at this point I wouldn’t rule that out. I get about two good days with no issues at best and then something.

Mike says I need to download new firmware for the control board, so I have to take my box and pc home to do that bc I don’t have good cell service and or internet at shop yet. Or he said they would send me a new control board.

Did those 2 holes have that weird G1 with no actual coordinates?

they think they know what is causing it and apparently Im the only one having this issue. OF COURSE!!!

Iv unplugged the control box from the pc when the pc is sleeping bc it still keeps the control box lit up. they think there is some storage issue or buffering issue very small that builds up over time. So resetting the control box is what I gotta do for now, so we’ll see if that works. new firmware might work too but they said that is not 100% guarantee.

I also just noticed. On the pic I posted on feb 10th on here it says error happened on line 651, well that same line happened on the same file again yesterday. It would lead you to think it is a file or post process issue but again, why aren’t my dozen other files doing it, its only certain ones at certain times. Iv re post processed some of them also and they still give me the error.

If I can get this resolved great, really hoping to not see the freezing issue again.

I looked at some of my Sheetcam files and they have that G1 with an F(speed) line and no coordinates in some spots. I can’t figure out why it’s there, but it hasn’t ever caused an error on my Pro table

thanks good to know, yah I agree I been using these files since I got my PRO well over a year ago. Some days they work flawless on the XR.

We have addressed the 38.2 motion control issue in FC. It was due a rounding error in the way arcs are written in the GCode. To resolve this issue simply update your machine firm ware. With the PC connected to the internet open FC and click help in the upper left hand corner. Click update machine firmware, allow it to update, then simply close and reopen FC to complete the process.

Thanks Cam, I have been in direct contact with Mike for a while, its been helpful. I been dry running FC all day and it hasn’t given me any errors. Im going to be doing a production day cutting saturday, I’ll keep ya posted.