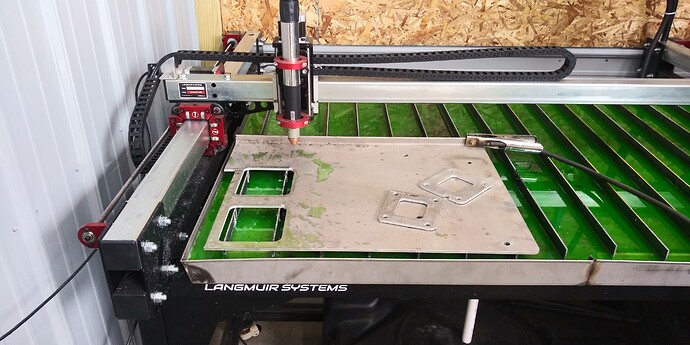

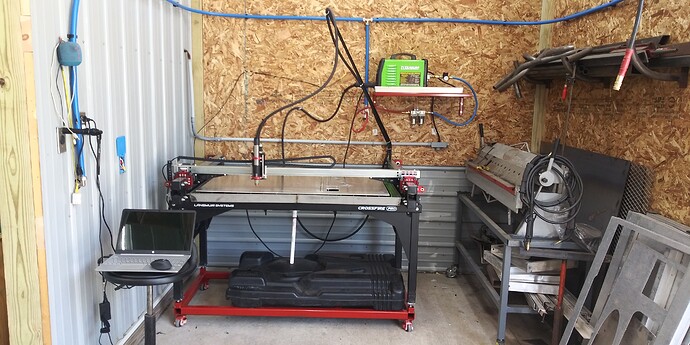

Well couldn’t be happier with my purchase of the crossfire pro. Finally got to do some cutting on it and it works flawless.

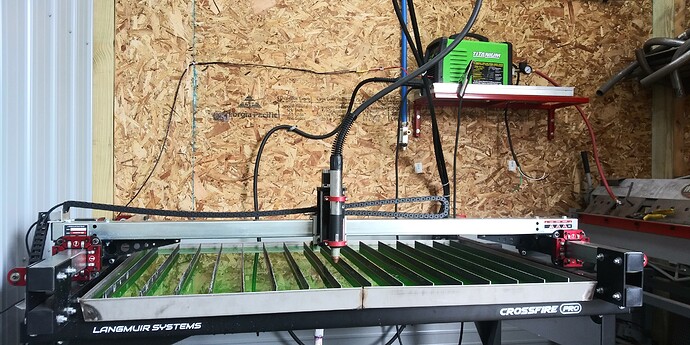

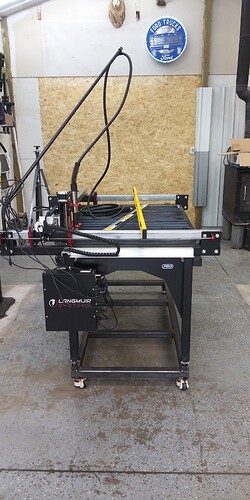

I installed drag chains, built a roller frame stand that the table sits on ( table adjusts at all four legs).Table is not attached to the roller frame it is free floating have adjusters sitting in square tube so table don’t slide off roller frame. Using a old portable basketball hoop base for water tank( 27 gallon capacity). greencut 9010 water additive. Titanium 45 plasma cutter with plasmadyn x45 machine torch. Purchased sheetcam and using inkscape .

I got a lot of these ideas from you people on this forum after hours of reading what has ben done.

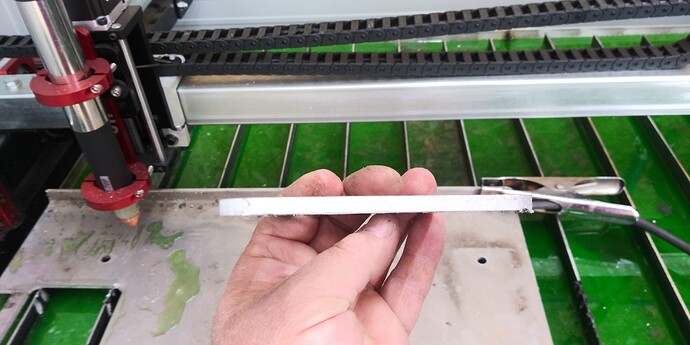

I have a little over two hours of cut time on table and 593 pierces so far ,cutting steel and aluminum cuts look great.

Still have a few things to finish up.

will load pics.

Sorry about pics guys ,ben busy tired…

clever use of the basketball hoop stand. perfect for holding the water. makes my ag sprayer tank look porky

Very cool!

Thanks guys.

thank you James, I see these old hoops every where being thrown out so I figure why not.

I will post pic with pump I’m using for now to fill table.

I have been planning on building a roller frame pretty much exactly like yours (metal is in the garage waiting). Do you like it? Anythings you would do different with your design?

Looks good

Thanks for posting the pics

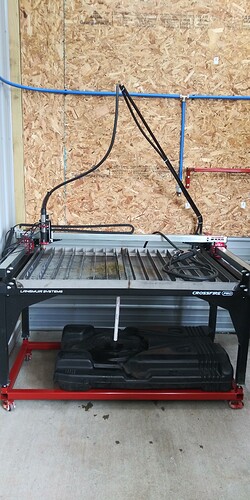

Hi Lanty , Yes I like the roller frame. It rolls easy and with table floating I don’t have to worry about torsional twisting on the plasma table. I used 1/2"x6" carriage bolts for table adjusters ,3/16" x 2"x2’ square tube for roller frame. Its rigid…

This is a great post, glad to hear it. I ordered my PRO last april for a summer Job I expected to get, but is was delayed into september. My plasma cutter is one that I need to mod myself to make it work as well. With all the negative stories on here, I basically have let it sit in the corner in its original boxes to this day, and have been thinking about selling it. I’m not that confident that I can save this place in this economy, and another half working project is not in the cards. But, with your success story I am more encouraged to put it together.

Thanks

Don’t let the negative story’s discourage you kw. This cnc plasma system is a new venture for me as well, and I am enjoying it as I learn new system and challenges. I have ben fabricating 40 years, stick welding, MiG welding, tig welding, oxy acetylene and hand plasma cutting.

I think a lot of problems with cnc cutting is bad wire splices for torch on/off at plasma machines and connectors not tight at firecontrol box ports and lose wire at pins inside of the after market machine torch( I had a wire not pushed in on plasmadyn pin ) easy fix works great on my pro table. don’t throw in towel yet…

The sub-frame roller is exactly what I am planning on doing, thanks for posting, pics help with design. Did you cut the legs down any to accommodate for the added height? Looks Great.

Also, what are the dimensions outside to outside of the sub-frame? length and width. I would like to do this first before I start to build my machine. Thanks again.

I did not cut table legs down , I wanted the extra table height. I will get measurements for you in morning.

Thanks for sharing, I can get started on my sub frame now.