Do we know if it fixed his yet?

Not yet, I’ll check out the cup tonight and see if I can find any blockage. If so I’ll clean it out and give it a test run.

I took the cup off and put a light under it. I could see light through each of the holes, but passed a wire through each one anyway. Re-installed, still beveled.

Then I rotated the torch 90 deg and the bevel followed. I’m going to order a new cup and I’m about due for a new set of consumables anyway.

Could you post a close up picture of your current nozzle.

Just as a idea, could you lower your amps to see if you get changes? I know when I lower my amps it thins my kerf, slightly.

Bob

Took some pictures with a microscope, did not come out as clear as I wanted.

Pictures 1& 2 are from the current nozzle.

Pictures 3 & 4 are from the start of these 1/4" test cuts.

Picture 5 & 6 are of a new nozzle.

Both sets of used nozzles were new when I started cutting the 1/4" pieces, all with bevel on one side. I have cut some other thinner material in between some of the test cuts, which is why they appear to be well used.

Is there a few different nozzle orifice sizes above?

I see some have The telltale shelf of a wider diameter orifice and some don’t.

And I’m sure it’s been asked or commented about somewhere above but you have a dry air source utilizing a desiccant cell?

Those are all 50 amp 1.0 nozzles from George.

Compressor is in a temp/humidity controlled shop. My current air filtration equipment is a Water Separator, followed by a 5 micron filter, followed by a 0.3 micron mist separator.

So you operate no refrigerated air dryer and do not operate a desiccant cell?

How do you deal with the rest of the water vapor in the airstream?

I believe those mist separators are for oil?

Correct. Technically there is another filter ahead of that coming off of the air compressor, but similar to the 5 micron filter.

The equipment listed above.

Correct, mist separator is for oil.

It’s probably not the cause of your bevel, but water vapor will destroy your consumables very quickly and lead to poor cut quality. At the very least, you need to add a 1 quart sized dessicant dryer and a motorguard filter in the line going to the plasma cutter.

I will have a very nice drying setup at some point… I have access to the equipment, I just have to wait until it is available to me.

I agree, I don’t think that is the cause of the bevel given how consistent it is on one side of the torch.

Hey Bob, I did try lower amps by accident. I didn’t adjust upwards after cutting thinner material. It resulted it poor, incomplete cuts I believe. 45-47 Amps seems to make very nice clean cuts, but bevel of course…

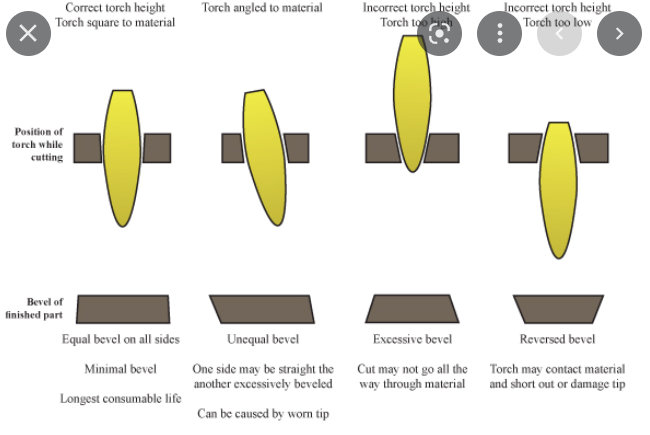

here is something that everyone needs on the wall of the shop…

this wioll help determine most causes of bevel…

you need to look at both sides of the cut to see what is going on

That’s post number two on this topic @toolboy ![]()

welll…sometimes people need to be told 2 times to get it right…ask my wife…she tells me that all the time…ahahahahah

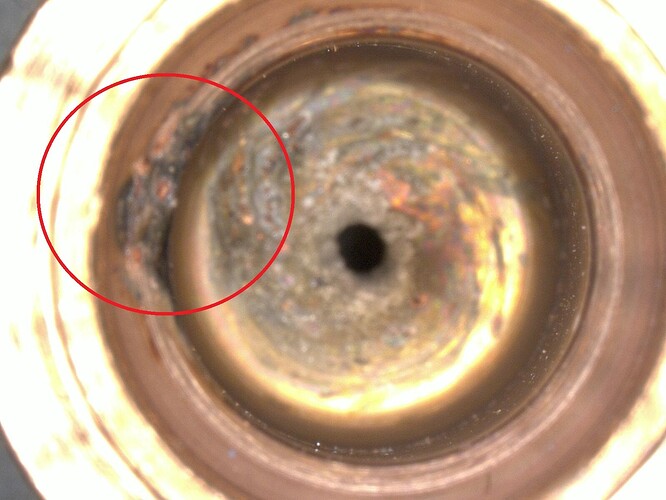

What does your swirl ring look like? this area shouldn’t look like that. The swirl ring covers that area. If i’m seeing the picture correctly. And you defiantly have a moisture problem.

Swirl ring looks new, That spot is actually inside the nozzle. Here is a better picture of the location

Ordered consumables and cup from George’s shop yesterday.