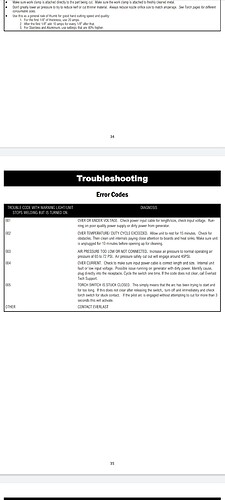

Bought a brand new Everlast 82I was working fine only cutting 10 gauge 35 A now I’m getting an EO4 code check voltage coming in 240 single phase

Any help would be appreciated thank you

Tom

I don’t have a everlast but sounds like the machine is not seeing the voltage at the receptacle it is looking for. Test and see what your voltage is at the receptacle/plug and see what it is

Thank you for your response I had check voltage at the receptacle and it is 244 manual says you operate at 240 v +or - 10% when I cannot find what does it mean when the red LED comes on along with EO4

Would take a picture of it but I can’t figure out how thank you

Thats good voltage. See what happens when its cutting. You may have a drastic voltage drop while its operating or when the compressor and plasma are working at the same time. E04 is over voltage. What red light is coming on? Maybe duty cycle or overheating?

I’ve had the same issue with my Everlast 62i. Seemed to work, then setting for a couple of weeks I’d get E04 when turning on the 62i. I found that the torch has two small spring loaded pins under the tip cover (bell shaped part) and on of the pins wasn’t extending. After cleaning and getting it to spring out when pushed, worked fine without error. I use a water table with mine, so had a second occurrence, but this time it was wet under the bell part. Looks like my anti-corrosive additive for the water tray (Pico Quenchguard) May have been getting to these little contacts under the bell. Rolled a rubber band over the bell so it dropped in the gap where the bell is just away from the black torch main body. Hoping this helps keep the small pins both dry and not gumming. This condition caused intermittent torch firing during the cut leaving uncut gaps.

Some silicon grease on the pins would help a lot. Also around the brass torch head were it goes into the plastic cover helps keep water out.