first legit cuts i made, 75 IPM, 45amps, 1.1MM Tip 1/8" plate, basically just light taps with a chisel and dross fell right off.

4Can I ask why you guys chose the 50S over the 60S? Was it purely cost? or does the 50S have advantages over the 60S for cutting thin material?

It’s probably just what each person plans to cut. The 60s will obviously cut thicker but the 50s will cut 3/4”, and for me personally that’s more then I will ever need so a 60s would just be a waste of money

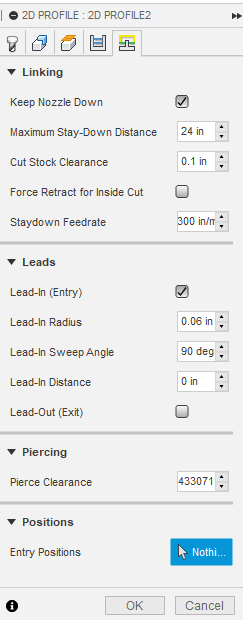

Whats Everyone setting their pierce time and linking too? I have been setting mine to .5 seconds for pierces on 1/8" plate and basically these settings for linking and leads…

I use the same for linking values but I customize the lead-in/out for the design I’m doing so I can adjust for different objects - some won’t work well with the settings you’re showing because they’re too small or convoluted.

could you give me an example? i have had an issue 2 times now with these settings where my first cut… is “delayed” maybe 1/4" and i have to pound out a circle or something… this is a cold cut where its the first cut after turning the plasma on.

I have been setting my pierce delay to 1sec, when I tried .5 I wasn’t getting good cuts on circles

That’s another issue. @oneupperformance is correct - your pierce delay for the initial cut is too small on startup (although it may be fine when it warms up). You can address that in two ways - either define 2 toolpaths, one for the initial one and one for all the rest. You’ll generate 2 TAP files for the project that way. The downside is you need to run 2 files in Mach 3 to do the job.

The other way is to increase your pierce delay. The downside to this approach is you’re leaving the head in position after the pierce is done and the arc established for your not-first cuts. That makes the pierce hole bigger than it needs to be and you need to adjust your lead-in parameters accordingly so that doesn’t create little notches because it overlaps with the cut line. But then you can do it all in one TAP file. (Pierce delay is set at the G-code generation level whereas kerf and other parameters are established at the toolpath level.)

The last way would be to look for the first pierce command in the G-code in Mach 3 (or a text editor) and change it from .5 to 1.0 - all the others would stay at .5 which you seem to be successful using for warmed up subsequent cuts.

Make sense?

This does thanks for the response, I have a file i can test this out on tonight, increase my lead in and pierce time. its a simple project for myself. I am trying to get some of this stuff dialed in before taking on customer projects. Thanks for the info guys

If you decide to modify the G-Code to slow down the first pierce and leave the rest, look for the first “G4 P0.5”. Change it to “G4 P1.0” and that will make the first one a 1 second delay but leave all the rest with whatever you specified in the pop-up window in the Fusion G-Code generator. It’s basically telling the machine to pause and hold the torch in position for a half-second. It comes right after the torch on command (M3). Changing the value makes the torch pause longer or shorter amounts of time.

increasing my lead in distance I felt like improved it overall cut a small part tonight… it was super clean and no lagged start. Thanks guys collaboration is the best!

Nice!!! What was your pierce delay?

Nice! Haven’t had to cut anything that thick yet. Thanks for the info!

What does the edge look like?

How much bevel?

Did you have you have to restart at all? If not you might want to check you set screws on the motor couplers.

im looking forward to watching this post. I have the 60s and will update my settings as I get them dialed in. I did however make a tap file with 9 separate boxes to test my amperages out on some lighter steel im working with. hope more people continue to jump on the Everlast and we share some good info. I set them up with ipm’s shown, figured ide pause between sets and change amperage from line to line to see what works best. it wouldn’t let me bring in the tap file, so I loaded as a dxf - download and change extension to tap did the same but for f360 as well changetof3d.dxf (93.6 KB)

.change extension to tap.dxf (3.0 KB)

I talked to everlast and they couldn’t give me a definitive kerf width, so I put a micrometer across the stock tips and came up with .06

Hell yeah, I’m surprised with the everlast too. Its night and day over the rw45.

Has anyone cut 1/4” aluminum yet? Planning on running some tonight…

Has anyone tried etching or gouging with their 50s? I want to adding in bend lines on some parts for an upcoming project.