Getting ready to install 220 line off of my 100a subpanel, what size breaker and wire shall I use?

Looks like it has. 6-50 plug looking at pictures online so you would need a 6-50R receptacle and standard in 6gauge wire, that what I just ran for mine.

30A for my hypertherm30 has not given me any issues on 220V

Since the 6-50 plug is rated at 50 amps, you should use a 50 amp breaker in case anything rated at 50 amps is plugged into it.

The VPC 30 is rated at 5.5kva at 230 Volts, a 30 amp circuit is more than acceptable. Depending on just how far you run the wire, 10ga is enough.

Would highly suggest if you install a 6-50 plug you wire it as a 50 amp plug with a 50 amp breaker and 6 or 8 wire. A 50 amp plug wired with a 30 amp technology is what burned down Cheryl’s She Shed! The difference in cost is not worth the risk. Just my 2 cents.

??? If you wired a 50 amp receptacle with 30 amp rated wire and 30 amp circuit breaker, and then plugged in a 50 amp rated plug on a machine that won’t draw 30 amps max. ??? The 30 amp will trip protecting 30 amps worth of wire. It’s not wise to over build a circuit. If you put a 30 amp machine on a 50 amp breaker and wire, the machines smaller cord would possibly catch fire and arc, well before ever getting to 50 amps.

True but then my question would be why does Razorweld put a 50 amp plug on a 30 amp machine?

Surprisingly sir, it’s even the same plug on their 45. Where’s the “shrug my shoulder, I don’t know” emoji, about now. Lol.

Truth is, it’s a good hardy plug that is connected to 12 AWG or if lucky, a 10 AWG cord. But know that a circuit breaker is there to protect a conductor, not a plug and there are common sense rules to follow when sizing a circuit in an electrical system. I personally use 50 amp twist locks on all my machines just because I like them but I only have 2 50 amp recepts in my garage that are sized for actual 50 (6 AWG wire/ Breaker) all the rest are 30 amp with the furthest having 8 AWG (75’ away) and the rest, closer to the panel are all 10 AWG.

Best, Steve.

I would wire the Amps according to the intended use…so if you only going to use a 30A machine, well let me rephrase this: if you’re only going to use a machine that actually draw up to 30A then use a 30A circuit and 30A wiring (based on length). If you don’t know, or think you might plug something that will draw more than 30 then bigger is better, you don’t wanna do it twice or constantly trip the 30A.

Your wiring might be good for say 40 actual amps, you still want the breaker to be less so that it pops first as a “sign” that you’re on your way to overloading things…I think that’s what everyone is saying too.

Definitely NOT a good idea to run a 30 amp circuit to a 50 amp receptacle. But if you think that’s all you’ll ever need, wire a 30 amp circuit, and change the plug out to a 30 amp plug.

That being said, much better just to pay for the bigger 50 amp circuit now. If you upgrade your plasma cutter, run a large air compressor, get a 220v welder, etc. , you will need the 50 amp circuit, and be mad you cheaped out.

You can put as small a load as you’d like on the 50 amp circuit, you can not put a larger load (over 30 amps) on the 30 amp circuit. And as you can see, the 50 amp plug is pretty standard, even on the smaller equipment. I see no advantage to running a smaller circuit, besides the slight cost savings.

6/2 wire should be what you need

I found this interesting myself. It looks to be common practice to put a 50 amp plug on a lot of equipment like this.

These are from my RW 45 a 50 amp plug but with 12 gauge cable I was like WTF but I get it.

Literally the cable that came on the machine.

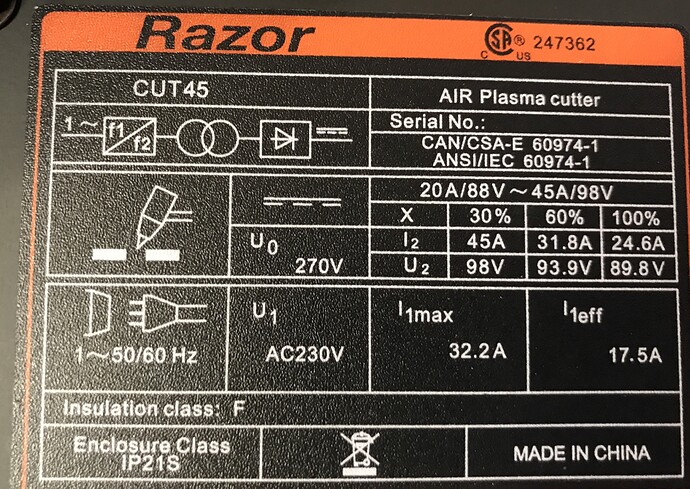

and the power label on the machine.

Now due to making things compatable with my electric brewing systems. I swapped my cable in my machine to a 30 amp molded plug with 10 gauge cable. Seems funny going to a lower amp plug with heaver gauge wire however I know I am more than good with my configuration.

This is what is the cord I installed on my machine but I already had several 30 amp recepticals in my shop.

https://www.amazon.com/gp/product/B00F17QD6W/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

Don’t be fooled by the wire that came with the machine. There is a ton of factors that go in to picking a wire for a certain application and also trying to keep price down. Not to mention the potential lawsuits a company could face if their product fails or causes a fire from their own negligence.

12 ga mtw (machine tool wire, which is most likely on your machine) at 90*C is rated for 30 amps. That’s just the wire and there are a bunch of other factors that could lower the amperage rating but you get the point.

Most of us think 12 ga is only good for 20 amps but that’s because of derating.

Also the machine label shows an inrush current of 32.2 amps and running current of 17.5 amps. So the machine running maxed out at 45 cutting amps would only draw 17.5 amps.