Hi Guys,

What kind of edge quality are you getting when you cut aluminum? The edges on mine are coming out “grainy” looking, rather than smooth, like with steel.

So, is this the nature of the beast, or do I need to do more tuning?

Appreciate your insight, thanks.

Ignore the chatter on the top left part, I was going WAY to fast. Top surface is actually angled ~5 deg and was stood up on its side so is technically an edge. 1/2” 4 flute 35 IPM 0.003” clean up. I’ve found surface quality seems to be pretty good up to 35-40 IPM with a <0.005” clean up pass.

That’s just how aluminum cuts with plasma. The edge looks more torn than cut and the dross is hard to remove without damaging the surface of the piece.

OK, thanks Dave.

Sorry WD40, I should have mentioned I was referring to plasma. Thanks for the reply though.

@curmudgeon Why no pictures?

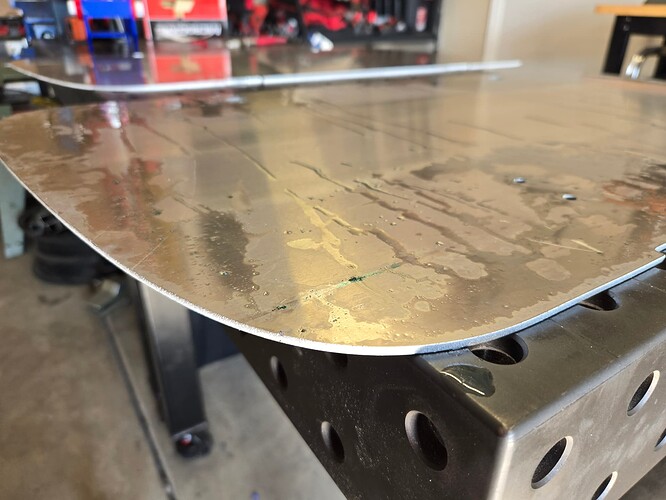

Here’s my aluminum fresh off the table - it’s grainy for sure but I use an air compressor too and no gas

At least it’s dross-free as those pictures are the bottom side

I was just playing around with some 3/32 I had, cutting random shapes when i noticed the big difference in edge finish compared to steel. I am getting some bottom dross, but it seems to knock off quite easily. Those cuts of yours look great!

I guess that’s the way aluminum cuts.

Aluminum only melts from the plasma heat and it conducts the heat faster than steel, hence a raggedly finish. Steel reacts to the plasma and actually burns so a much cleaner cut.

Yea, I guess it is the same as when oxy/acetylene cutting. The steel oxydizes and cuts cleanly (if done properly), whereas aluminum will just melt and get blasted away.

Should have realized that myself.

Thanks.