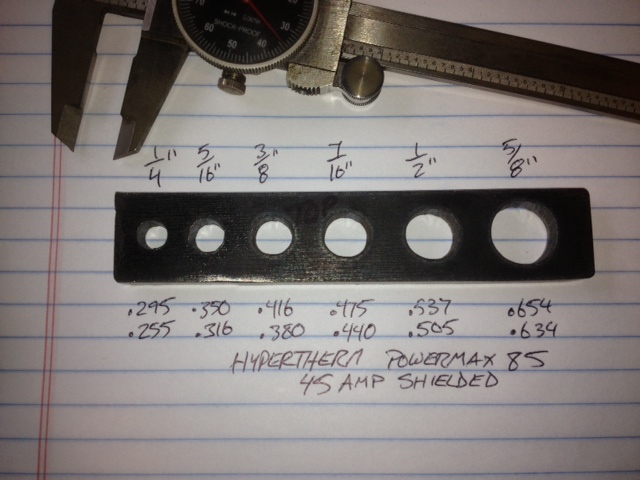

Here are some sample holes cut in 1/4" steel using a Hypertherm Powermax 45 amp shielded process. This shows the nominal sizes that I drew the holes in order to allow for a bolt to drop through. You will not get “taper free” cuts with any air plasma system, so you must understand how the process works in order to make the most of its speed and low cost per cut capability. Notice in this that there is more taper as the hole diameters get smaller, this is due to the taper of the arc as the torch makes a series of left hand turns while forming a circle. Note also that all holes must be cut in the clockwise direction to minimize taper, and the torch must be at the correct (from the cut charts in the operators manual) cut height. Higher height will produce more taper, cutting in the wrong direction will produce more taper. All outside cuts must be done in the clockwise cut direction. Jim Colt