Hi everyone had you tried oxygen gas for thin steel sheet for cleaner dross free cuts

if yes does you put only oxygen without air or both can together does the job.

I did search nothing find to test how does actually plasma works only with air compressor.

any suggestions would be appreciate. Thanks

NEVER EVER USE OXYGEN WITH A PLASMA CUTTER!!!

Welcome to the forum.

Yeah - I’ve only heard of nitrogen being used in certain rare situations.

Thankyou! I am thinking for one of LS table but our application needs clean cuts for stainless thin sheets. we have other options like laser but it is now very higher costs

As James said, Nitrogen works well but laser is what most are going with for thin SS.

I’ve heard of oxy on laser, but not plasma. You can get very nice cuts on plasma, but laser is more precise and much more expensive. Depending on what you are doing, plasma may be all you need, but you’d have to get some samples cut both ways and decide what’s acceptable to you.

we do make sign letters in stainless we need to put 1 inch of wall around edges with manual soldering if we have dross in bottom edge its very hard to cleaning in steel.

(edit . When I replied to this I thought it was a lot more recent than it was)

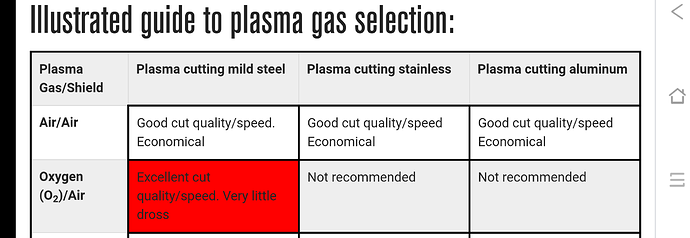

This article is one of the best I’ve found so far discussing all the different gases you can put through your plasma torch.

Hypertherm gas selection article.

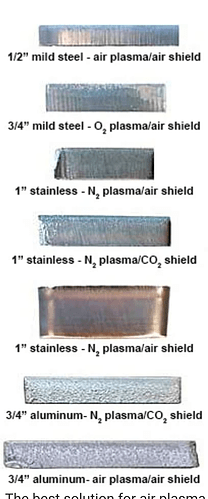

Pictures because everyone loves pictures.

from that article.

I have only tried compressed air so far.

Does anyone have any pictures of stainless they’ve cut with different methods straight off the table? Ugliness and all.