Well Dang. If this is the case, nobody try this. Thanks Tankueray

No problem. If you installed them, open the English 45xp shielded tool table and see if there are two weird entries at the bottom, they’re the code snippets. Delete them, then go to the rules and delete them all, they should be red (error indication) because you just deleted the two snippets. Then file - save tool library as - something that is not your default. That cleans up that particular English 45XP Shielded file only. I didn’t feel like messing with any of the others. However, open the tool table again and reference it against your manual, it does not match mine. If you’ve upgraded to a duramax torch, reference that table (from Hypertherm) instead.

Edit: I’m sorry, nevermind, uninstall them all and start from scratch if you have to. I just opened all four of the 45 and 65 shielded files in an editor, and they are way too much of a mess to think that editing the tools individually in Scam will work without issues. There are extra settings and g-code addons in many of the individual tools. It seems that AvidCNC spent a lot of time to dial them in for their machine, and I’m sure they’re lovely, just not for us.

Also, FYI all, if you have a Hypertherm without a duramax torch, they discontinued many of the consumables for the older torches last month. Stock up now, or you’ll be buying a replacement torch soon**. (That goes for other machines that use those consumables as well, Snap-On used to sell a plasma that was about the size of a tombstone welder that comes to mind.) **Another FYI, call your local dealer, Hypertherm has a torch trade-in credit for an upgrade to a duramax - get it now because they’ll probably stop offering it since it will be your only option.

Yup got it. I just loaded my old tool set in that i already had. Running a HT85 so im good on torches. this unit came with a hand held torch and the machine torch.

Looks like it’s not downloading again. Any way you can fix that again?

Works fine for me.

Had to right click, open in new tab to get it. Thanks!!

windows wont let me drop the “.dxf” or I’m doing it wrong. any suggestions?

Might be a dumb question here. I’m looking for the complete tool set that will work with SheetCam that feeds into Firecontrol we have the AHC as well. I have a Hypertherm 45 XP. I see a lot of links here and not sure which one to download. I’m trying to make the set I have work that I used with Mach3 but I need all the pierce info. updated it seems. I changed my tool set thinking it’s what I need and save the tool set only to get an error in Firecontrol of pierce delay should be 0.5. Not sure if it’s the file I’m using or the tool set. Very stressed out here. Can someone point me to the one I need to download that would be a complete setup please? Any help in getting me up and running would be greatly appreciated.

The parameters are all in the HT manual. But you’ll want to add a half second to the pierce delay. HT calculates it from when the solenoids click but the Crossfire doesn’t have that feedback so it calculates from when the command to fire is sent. There’s a delay between that and when the torch actually fires up so that’s what the extra half second does for you.

You can fuss with the extra half second - a qtr or slightly more will work on some machines & material but a half second extra works for most everyone.

I used the HT manual settings and I thought I was doing something wrong. I will try changing the pierce delay to each tool and try again. Thank you.

Morning James,

I have setup your tool set and added the 1/2 second pierce delay to each tool based on the HT manual and what you had. Did you need to do any adjustments to pierce height?

What we have going on: touch goes down, touches material, goes back up, then torch fires, goes back down to material and starts to move. It leaves a hole in metal. I’ve been working with lead in. Based on videos I’ve been watching they say to select ARC and set the measurement. What do you set your lead in at/ lead out? Do you change pierce height from manual settings? We’re just trying to get tools setup correctly.

HT45 machine.

We’ve been using 14g metal to test things.

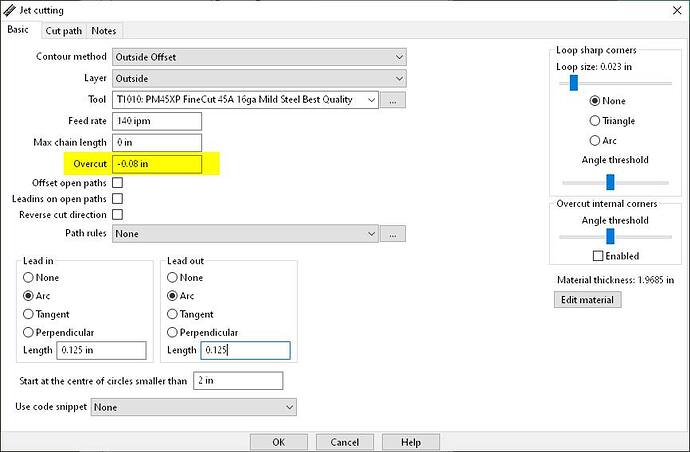

@Mert570 Yes, to keep the hole off your project use Lead In / Lead Out. This may sound silly, but it does work. Use a positive “0.125” - “0.25” lead-in and out, but with a “negative overcut”. Something in the “-0.08” range to start. This will almost eliminate the issue of seeing nipples or divots in your work!

This is what it creates using SheetCam. The red arrow points to the place that doesn’t actually get cut. In software, it should leave a little piece of metal there, but the pierce blows it out.

That’s working correctly. The 0.15 pierce height is so that the torch is protected from blowback on the initial pierce when it’s stationery. Later when it’s moving it will lower to the cut height (0.06).

I almost always use Arc as well. However, if the cutout is tight, sometimes a perpendicular entry is all that can fit. Arc is better because it’s going to make a smoother transition into the cutline than if you you perpendicular where it has to do a right angle turn to move from the lead-in to the cutline. But there’s not always enough room to do that.

I usually start at double my kerf (0.12" is my default) so it can depend on the material you’re cutting. But 0.12" is a good basic setting and doesn’t require a lot of room in the scrap side of the cutline. I will tighten it up for smaller cutouts where there isn’t enough room to swing in - I usually setup different paths based on what I’m going to use for lead-in values & type of cut (inside, outside offsets or no offset at all) in fact.

I don’t usually use a lead-out as the HT is good about extinguishing the arc pretty quickly so I don’t usually get any kind of ending divot. But if I do, then I’ll use the same settings for my lead-in so it’ll move aside before shutting off.

The link opens the Hypertherm Pdf manual ???

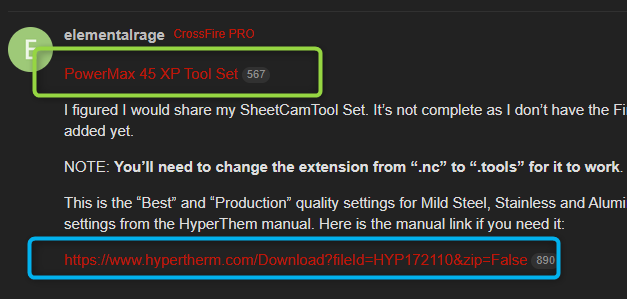

Click the link circled here in GREEN in the first post. The link circled here in BLUE is the manual.

@elementalrage

Thanks, and sorry for not reading the entire thread. I see you have had to answer the same question twice now!

I downloaded and installed the tools in SheetCam without any difficulty.

I’m, setting up SheetCam, and read your ToolSet offer. I don’t know how to change the extension from “.nc” to “.tools”

Also in the setup of SheetCam it asks for a “Post Processor”. I purchased the Razorweld with my Pro table Oct 2021, I went through all the entries but cannot find one close to a Razorweld or even Langmuir.

Do you have any suggestions?

I really appreciate your time and sharinng

post processor is here: Downloads | Langmuir Systems

I made a loom video of how to select the Post Processor in Sheetcam. The post processor is for Firecontrol, not the plasma cutter. The current version of Sheetcam should already have the Firecontrol post processor in the list. Loom | Free Screen & Video Recording Software

Thank you for this information. Saved me a ton of headache