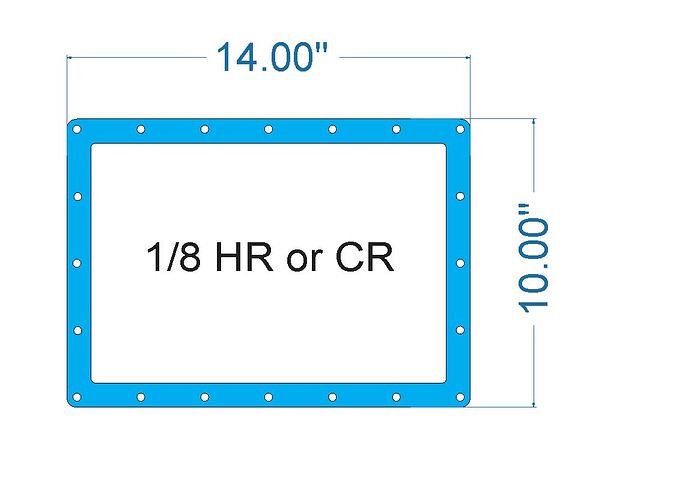

steel tank support frame.dxf (10.1 KB) Here is the DXF for the backer plate and gasket if anyone wants to perform this mod.

So you going to patent that repair? ![]()

Looks very nice, I hope to find some free time and do the same thing

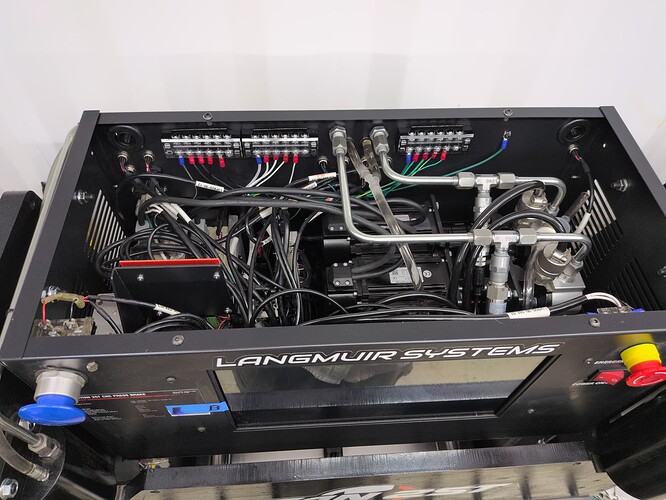

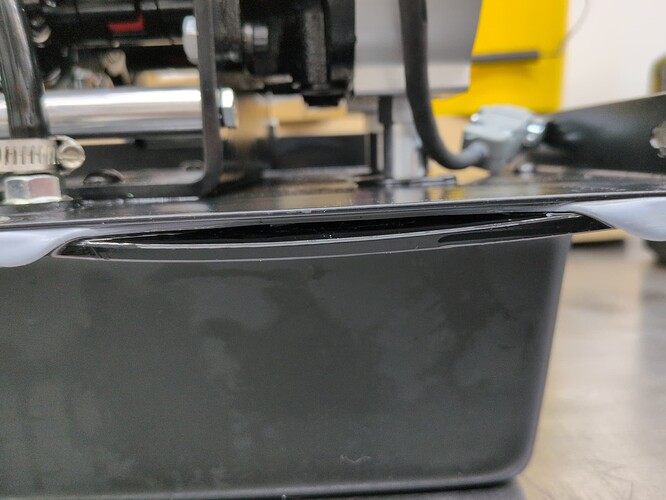

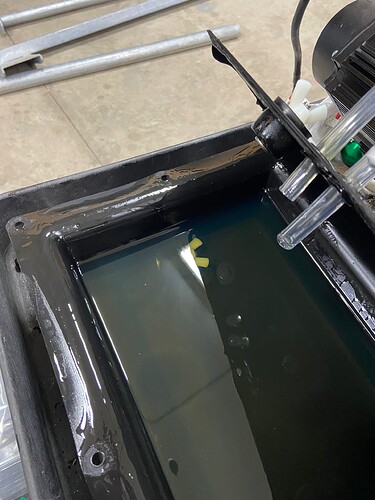

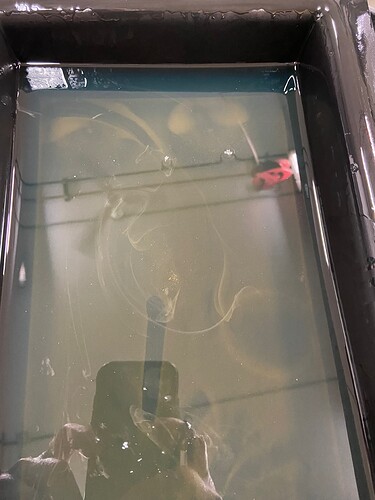

I’d like to see Langmuir do this mod to ALL machines before they get sent out the door…so no one has to suffer through this headache again. After it’s all figured out, it could be completed in 8-10 hrs. there are a few hard parts like getting the bolts out of tight spots and it takes 3 or 4 hose downs to really get all the oil out of the seams and electrical connections. I simply cannot tolerate oil leaking out of a brand new machine and the only way to get it to stop, is rip into it and get it done. all cleaned up and ready for service again - until the next problem rears it’s head ![]()

It’s the only way to really get all the oil out after a major dump like this.

The tank doesn’t have much churn during operation, so I don’t think your leaks are due to the tank. I would just start from the top of the hydraulics and feel your way downwards. Message me which of your parts that are wet is the highest up and I can help you fix up that issue. I wonder if this is just a loose plastic return line on the barbed intake. If that is the case some zip ties or a hose clamp would fix that.

Very impressive work there! The rubber gasket is a great solution.

Note that not all rubbers are suitable for hydraulic oil.

True

Materials That Offer Excellent Oil Resistance

Nitrile

Viton

Neoprene

I used Neoprene on this .063 thickness Amazon.com

I have used rags trying to find a leaking fitting and have not found anything that leaks. I even wrapped shop paper towels around the fittings and ran the machine and all of the towels are still dry. I’ll take a look tomorrow when I’m back in the shop and see if I can find anything leaking. I think I’m going to have to take it all apart though soon as oil is everywhere inside the electrical cabinet. It’s leaking all around the seam under the cabinet.

Sounds like it is just a rim leak. We might have over-filled your tank. The fluid doesn’t slosh around during operations so it shouldn’t continue leaking at this point. I’ve messaged you with some more suggestions on how to handle it.

Looks good!

This might explain why despite cleaning it well after the oil covered delivery I’m still getting some leaking oil out of my Titan. Further investigation may be warranted on my part.

If you have one of the machines sent out that has a tank with only 8 bolts in the top - it’s going to leak until you tear it all apart and fix it.

Same thing here

I see someone must’ve pushed the fill plug through the hole because when I pulled the top off, there was an extra one in there.

Also found a lot of sediment in the pan for what little bit of use this thing has had. Hope this isn’t the start of another problem.

My machine was delivered end of Jan 2025 - IDK when your machine was delivered, but every machine before mine, and many after, were sent out with this major design failure. I know there were at least two failed revisions for this issue since, with more bolts and ‘different silicone’ - neither of which really fixes the problem since the sealant does not stick to the Kydex vacuformed tank. The only correct way to repair this failure is with a gasket and fasteners every 3”. My tank also had the whiteish/grey sediment in the bottom of it, which I assume is the liquid sealant breaking down in the oil. I’m sure Sam will send you a new tank and lid, but that’s it - no gasket, no oil, no credit or reimbursement for your machine downtime, labor, trouble or effort cleaning up their mistake. LS should offer something for those who were delivered a machine with an obvious manufacturing design failure. They should also send out a warranty update to inform everyone who was sent a defective tank IMO. I’d like to know exactly how many bad tanks were delivered to date. The “fix’ they came up with isn’t really a fix at all - a bandaid at best. Notice how zero sealant was adhered to the tank? ![]() The “new silicone they sent also does not stick to the tank for more than 3 weeks which is likely the full cure rate. Well, at least you took the time and effort to fixing this the right way

The “new silicone they sent also does not stick to the tank for more than 3 weeks which is likely the full cure rate. Well, at least you took the time and effort to fixing this the right way ![]()

Why a new lid?

They added a few more holes in the lid and the tank to try and fix it - but it’s a pathetic attempt IMO, and not nearly enough holes. Also having to scrape all the old sealant off the old lid, and clean it all up in spotless condition for re assembly is a real pain, plus the powder coating is going to get jacked up in the process - I didn’t think he was going to send the lid, but i’m glad he did in the end, hopefully he sends you one as well.