Cletus could you send me one of you simpler job files? I’d like to load it and try to see if I get the same results.

Here yuh go

Hanger1.dxf (29.3 KB)

Hanger1.job.pdf (17.1 KB)

REMOVE THE .pdf FROM THIS ONE

I just cut one in 16g Galv Steel and will send front and back pics

Cletus, I didn’t have a chance to try the G-code tonight but I was looking at your photos and see the same divots that I’m getting in your cuts as well.

Maybe you could try a lead-out of 0.15" as well and/or lessen the pause at end of cut

Quick glance shows outside offset, that would put those divots in, you should have 3 inside offsets and pierces and 1 outside offset with pierce.

Also I noticed G40 which cancels offset, not used in FC

G53? That is machine coordinates

And G90 and G91 on same Line? Thought 1 was absolute and 1 incremental, different in plasma land? I don’t have both and figured it wouldn’t work with both.

Last bit is just an observation

What post processor are you using?

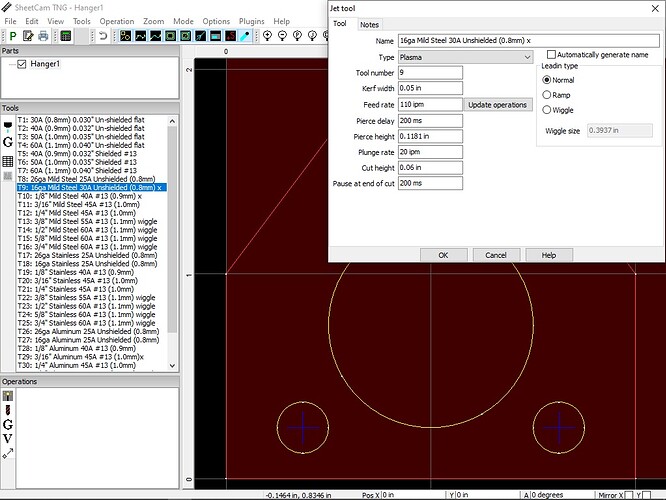

I am using the FireControl v1.6 post script, downloaded from Langmuir Systems website.

It seems much better adding a lead out. I will cut some more and post photos.

I had the same issue and I changed my consumables and it was perfect, I called them little blowouts but it was only at the beginning of the cuts. I only had a few cuts done prior to this happening too, but I live next to the ocean so I’m guessing the moisture killed my consumables, so I put a diy copper draining system. Change your electrodes and tip and try it…

Thanks Shane, I will try that since u just bought some consumables. Nice moose!

Curious Shane, copper draining system on what the water table?

oh sorry i should have mentioned that the copper setup was on the air line, because im new to this as well and i went through my tip in like 1 and a half sheets of 16 gauge, and i was reading post and seen that moisture in the lines might be the cause of the tips being ruined so fast, so i was thinking first it might be moisture in the lines, so i did the copper DIY setup for the airline along with the water separator, and they may help going ahead but my tip was already ruined. but i replaced the tips and it cut perfectly.