It is the speed from pierce height (.15”) to cut height (.06”). I’ve used the same number from 20 ga to 3/16”. Hope it works out for ya.

Thanks for the explanation Jason. I’ll give it a go and see

And as a FYI to anyone making these. 11 ga is to thick to fit between the bottom of the cap and the glass lip. Learned that after handing out a few of them. Nothing a little time with a flap disc couldn’t handle but save you the time and embarrassment. Cheers.

Ray download the fbomb I fixed and let us know results, I think that is the one with overlapping. Def. Use .2 pierce and bump up to 100ipm feed rate atleast on 14ga 30 amps and internal regulator at 75pounds, comp at 125 or whattever is stock, 120/150ipm on 16 ga

Any chance you can get a video of it cutting one out?

Yes, I will try to get one tomorrow.

Maybe someone can send me a tap file that is known to work and I can try it on my machine?

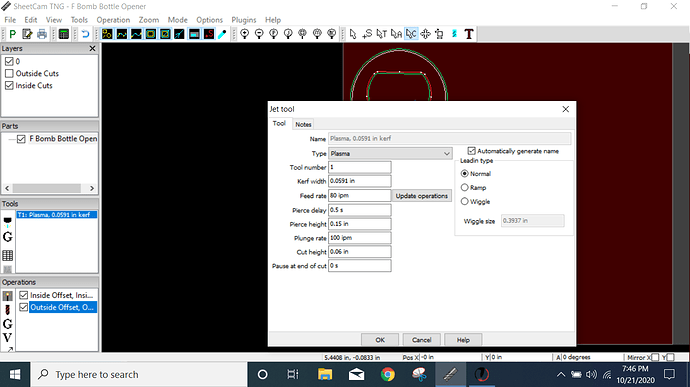

post a pic of the plasma operation also.

Also, you don’t need to create 2 separate operations for inside/outside cuts unless you are drilling/center punching holes or have straight line cuts that need no offset.

for your file for example, you can do 1 operation using outside offset, reverse cut checked and sheetcam will create the toolpath with the correct offsets for inside/outside cuts.

I was trying different approaches wondering if that would make a difference, it didn’t though.

The easiest thing is to zip up your .job file and post that. That will have everything in it.

No, that is the G-Code file. The .job file has all the SheetCam info in it and had, not too coincidentally, the extension ‘.JOB’. You’ll need to ZIP that up since it can’t be uploaded directly to this forum.

Ok. I’ll have to zip it with another computer the one that I’m using didn’t have the program loaded for zipping.

I have no idea (on vacation) what I use for cut specs/ ht etc it is whatever the FC post puts in.

However change peirce delay to .2 (.5 has it dwelling too long) feed rate bump up to 100ipm.

Also notice the lines of that fbomb on your screen? They are not straight or perpendicular, go to fireshare and download the one I fixed. I scale it at like 80%.

Let us know how the .2 pierce delay works, also def cut inside first and then outside.

I will check when I get home and see what kerf size I ended up with, it is w/I like .005 of cutting to size

This job file has five copies of the same operation which would attempt to cut multiple times. Delete all but one of them (right click on the operation and then select ‘Delete Operation’ from the popup menu).

As @GunTruck1776 says, the sides on yours are not orthogonal. You might want to try his fixed version.

I have changed all the parameters to the suggestions given but still getting the divots. What dimension should I put in for the kerf? I have set .030” and that has helped some I’m going to try taking it down further. What is a good cutting and pierce height?

I’m piercing at 0.118" and cutting at 0.060" my Kerf is 0.050"