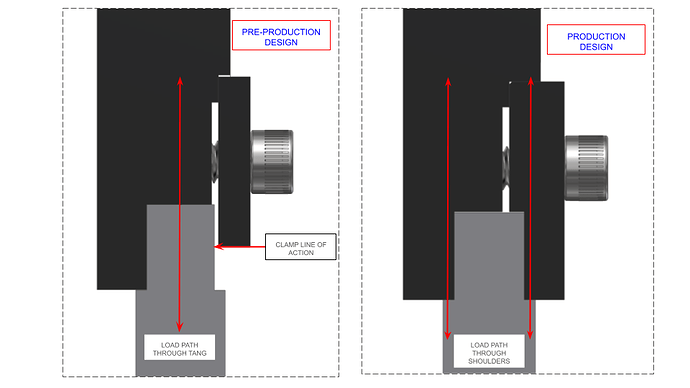

Hi all, based on customer feedback we have decided to make a change in how the punches are loaded when performing a bend. The original design was such that the load vector was through the centerline of the punch and through the end of the tang. Admittedly we went this route because it is more affordable to produce and our FEA did not show any adverse affects as a result. However, loading the punches through the shoulders is more appropriate and the way that American style tooling is intended to be loaded.

As a result, all press brake will come with the revision shown below:

7 Likes

Thank you for sharing the design development. Just to be clear, the pre-production version is the one you are going with? The production design could be problematic. Loads are shared between tang and clamp so the clamp is doing double duty, locking the punch in place and supporting load. From what I know of American style tooling, the loads only ever go through the tang, and in the European the load goes through the shoulder of the punch and the clamp does only one thing, clamp.

Thoughts?

The production design (image on the right) is what we are going with. Its hard to tell in the picture, but there is an airgap between the top of the tang and the corresponding surfaces on the ram and the punch clamp. Therefore the shoulders of the punch are taking all of the load and the tang itself is just there for locating purposes.

1 Like

Thank you for clarifying this

How will the 4 way bottom die be held on place? Looking at the available pictures it looks like it just sits on the base with nothing holding it in place. Am i missing something?

1 Like