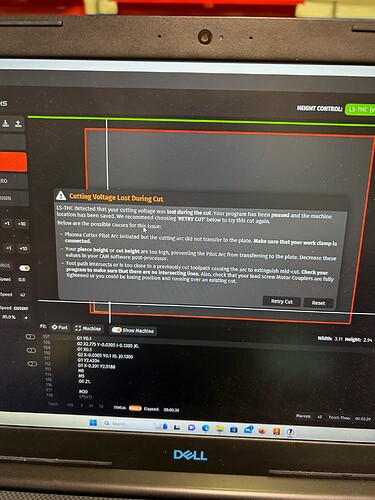

when I try to make a cut with my Hypertherm 45XP with machine torch it just scratches the surface and states Cutting voltage lost during cut photo attached I hope they open

Is there a chance you might have your hypertherms set to gouging mode?

What cut height are you doing?

What the thickness of material is that?

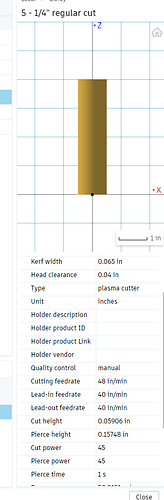

I see that you’re cutting at 47 in per minute

What amperage are you set for

trying to cut 1/4, not set in gouge, my xp is set to 45 amps, but it seems the THC is going high

@KSP227 Welcome to The Forum

What are you setting your cut height to in the program program?

On your VIM are you using the DVI input and DVI output connects to send the divided voltage signal to the langmuir electronics enclosure from your hypertherm?

You don’t need to use THC to cut…just FYI

here are my settings for 1/4" steel

i don’t cut a lot of 1/4" but when i do this seems to work good with my hypertherm 45XP

im using DVI input and DVI output and cut height is .059

This is the second time I have tried to cut new to it. First cut I made was 1/4 washer and it cut no problem now it just scratches the surface. I shut THC off and still same

Shut off THC & IHS and set your height manually and try to cut and see if that works.

Make sure your work clamp in on the metal.

Thanks for all the help, it was a ground clamp issue. The clamp got loose on the main XP 45 and was not getting a good connection

I usually use a grinder to get a good clean ground clamp point on a sheet

So I am suddenly having a similar issue. Tonight i was cutting 1/4" and the first piece made the interior cuts no problem but the torch would raise and only gouge surface after some inconsistent distance and eventually would stop cutting due tomloss of votage. Next piece (duplicate of first) cut fine, so did 3rd piece. Last piece acted like 1st piece, some areas on perimeter did cut all the way through, cut is severly beveled. After a few stops on 3th piece Ichanged consummables and it didnt make a difference. I moved and improved ground after 1st piece poor cut, thought I had fixed it then on 4th piece didnt seem to matter, i removed magnet clamp and c clamped ground to material. Still didnt fix it right away. I havent changed anything in terms of cable routing, moving the table, setting etc in over a year and I am getting 100 psi air at my powermax 85. I use the table weekly. Im cutting 1/4" at 45 ipm at 45A with 45A consummables and the hypertherm pierce delay and cut height, like I always have with good success. Any thoughts on solutiom? I should note i am on firecontrol 20.1 and have not done any updates since probably 2021, everything has worked so well i figured no reason to mess with it. I attached some photos.

And yes, i know the material looks really rusty but its really not that bad plus I have cut alot out of that scrap sheet in recent weeks with zero issue.

Go back and double check your settings just to make sure something didn’t get changed. Check to see if z axis isn’t binding on lead screw when going up/down. Make sure swirl ring isn’t damaged in torch and would double check air pressure. Do you have THC equipped table? if so look at voltage.

I doubled checked all my settings, absolute no differences. Yes I have THC on my table and my Z is not binding. Swirl ring has no visible damage. My air is very consistent at 100 to 105 psi (i have gage at back of machine and before water sepatator/filter prior to cutter). I went ahead and cut a few more pieces on that .25" plate and everything worked great. Went to cut some artwork on 14Ga 2 days ago and i lost voltage several times and the sheet of steel was clean. I somehow even lost steps in Y during a restart, seriously a disaster part, but I continued to see if it would continue but it just finish cutting with no issue. I cleaned the shield really well and changed out consumables (including swirl ring) and re-did part, did nothing to ground & it cut flawlessly like it always had before. Does it make sense if the shield is really dirty I could lose volaltage? Cant say Ive ever kept it real clean in the 3+ yrs of cutting and not having this issue.

When was the last time you replaced the o-ring, retaining cup and CNC shield on your torch?

Oring has been replaced once in the 3yrs ive had the torch but is pretty regularly lubricated. Retaining cap is original (never changed) but I have a new one on order. Shield for fine cut consumables has never been replaced but shield for standard 45A consummables has been changed within last few months. What gets me is the problem has now occurred on 2 different set-ups, different material, thicknesses, consummables, shields etc. It seems to be random but I think its electrical or ground. Replacing crimped end on ground cable this week.

You really need to change out those parts more. Like every few months as they are also consumables. Also change the swirl ring after every few tip and electrode changes.

I may be wrong but don’t think its your plasma cutter. I run a Thermal Dynamics machine and my Pro does the same thing from time to time. I always try to knock the fluffy rust off the steel with a wire cup and make absolutely sure there’s a good clean ground. When it happens I turn off the THC and reload the cut file. Works fine after that.