So I made my first cut today, AND EVER ON A CNC. I don’t know what possessed me to pick SS as the go to material.

The dross is worse on the top than the bottom. Almost none on the bottom. Also the cut has a tapper “V” shape.

Here is my setup:

Here is what I need help with:

The V shape cut. How to improve.

Are settings correct

Is the wiggle pattern in the text from the design, of is that an arc issue.

1 Like

The following atricle mentions that dross on top is too high IPM. See Step 6. Other great tips as well.

1 Like

nicaDd

August 8, 2020, 12:53am

3

The wavyness could be from loose couplers or loose lead nut mounting bracket on the X axis carriage

Use nitrogen not air and you will get a lot nicer cuts with SS

TomWS

August 8, 2020, 1:24pm

5

IMO, 230IPM @40A is way too fast for SS, my settings for 16GA SS are 35A, 58IPM but with a different PC so YMMV. However, I’ve seen that waviness before (in SS as it turns out). Check out Crossfire cut Quality issue - solved

I have not had the problem since modifying my slats…

1 Like

Okay, I’m back with an update.

All good advice and help, so thanks to all of you.

So here are the changes I made to drastically improve the cut quality.

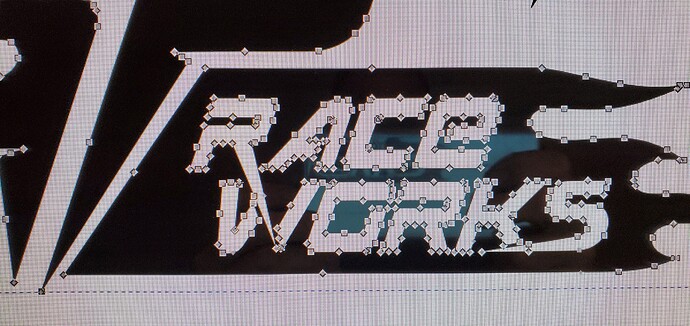

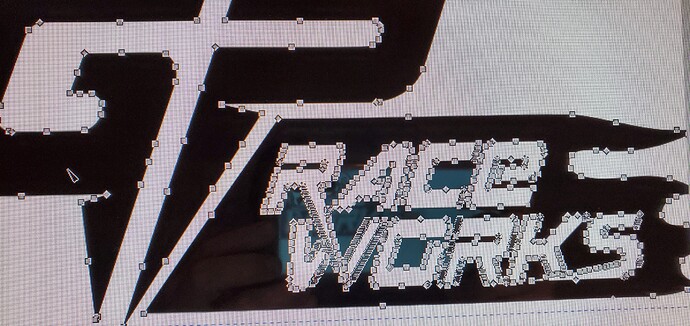

A guy on Instagram recommend cleaning up the file by reducing the number of nodes. This was the first huge fix. You can see the difference here.

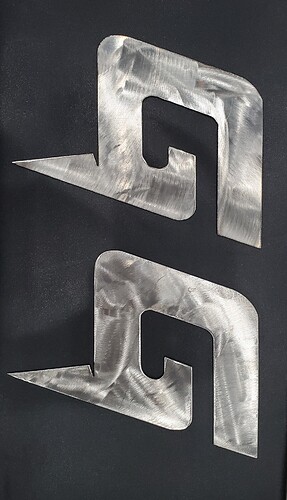

Adjusting the cut speed to 100imp completely eliminated the top dros, bottom dros was the same. But it also fixed the “V” problem.

Lowering the AMPs to 30 is also a big help also in line with #2 above.

In these images you can see the quality improve. A bit more fine tuning and it will be even better.

1 Like