I downloaded a .dxf file file to sheetcam. Ran the program to generate the path and then post-processed . I have height control. While the path was followed the torch at one point read the height over an already cutout space and therefore lowered and dragged the material. I wasted some expensive material. Was this how this .dxf was designed or was it how sheetcam generated the cutout?

So in the program it is cutting areas that have no material in them? Or did the material already have missing areas?

Normally the arc would extinguish cutting on open area and fire control would throw a lost voltage error.

Can you post a picture, DXF or G-Code for context.

Have you had any successful cuts while running the THC in the past?

Are you clamping to the material?

This “already cutout space” was likely something that was cut out of the sheet from another program. If so, neither Sheetcam or the DXF are at fault.

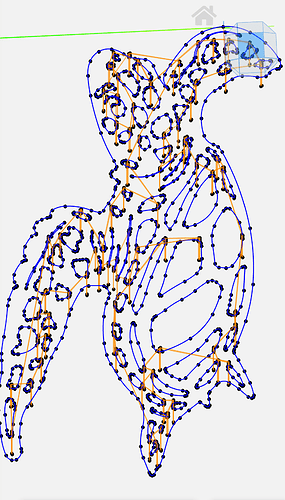

You have to make sure you have your part positioned in a way that the torch can touch down on metal at every pierce point. The start points for each loop are shown on the screen, so you can see where the torch will touch down to detect the material height. If you position your part too close to an already cut area, the torch may not hit metal and will dunk itself in the water until it runs out of travel or hits something. At that point, the program thinks that is the material height and tries to continue the program.

I bought this .dxf so please do not copy or use for anything other than diagnosis.

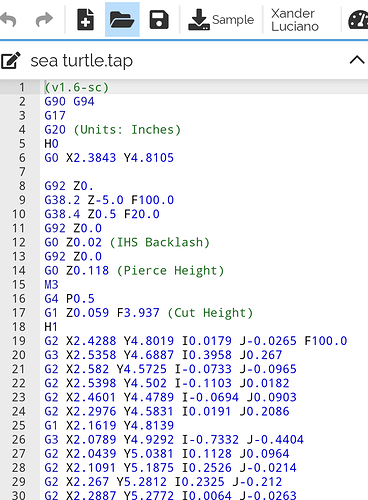

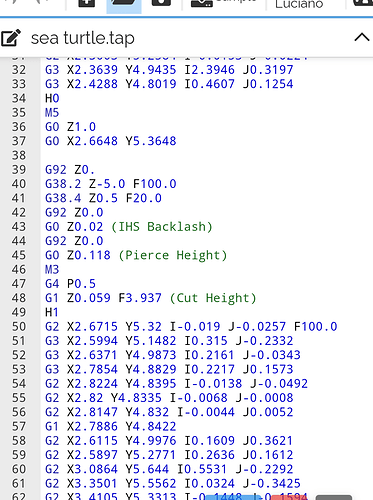

sea turtle.tap (120.0 KB)

Hope I uploaded this correctly. ![]()

I downloaded and ran the gcode thru ncviewer (ncviewer dot com) and the only thing i saw that needs to be changed is the cutting directions. the inside cuts should cut counterclockwise and the outside perimeter cuts should cut clockwise.

I didn’t see any overlapping cuts that would cause your issues.

It definitely we won’t pirate your image.

I’ll look at it more when I get back to a desktop but I’m just going to post the image in a few lines code.

Another thing I did was to use no lead-in or lead-out, as I got a warning. I still got the warning for some reason but ran the sim and it all looked good. Did a dry run also and looked ok.

THC has always worked great for me. It was a clean sheet of metal. I did a dry run to make sure it all fit.

Could you take a picture of the piece that was ruined.

Still can’t figure out why you ended up in the area with no material.

Are you having coupler slip?